Grab, Lift, and Tear.

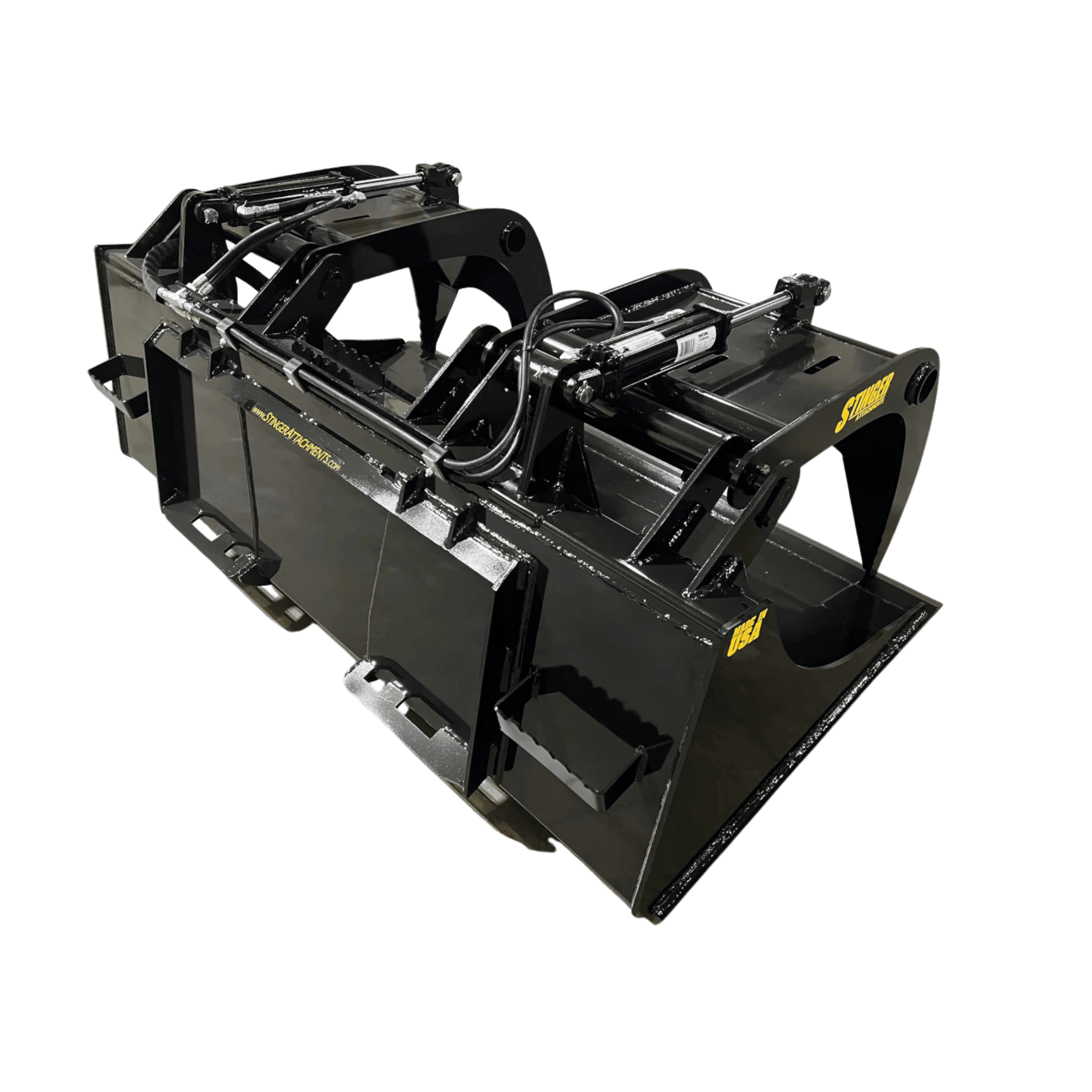

The Most Versatile Tool on the Jobsite. From sifting rocks to tearing down structures, a high-quality grapple is the workhorse of your fleet. Stinger Attachments are engineered to withstand the twisting forces of heavy demolition. We utilize Grade 50 High-Tensile Steel—30% stronger than standard mild steel—to ensure your tines don't bend when prying out concrete, stumps, or scrap metal.

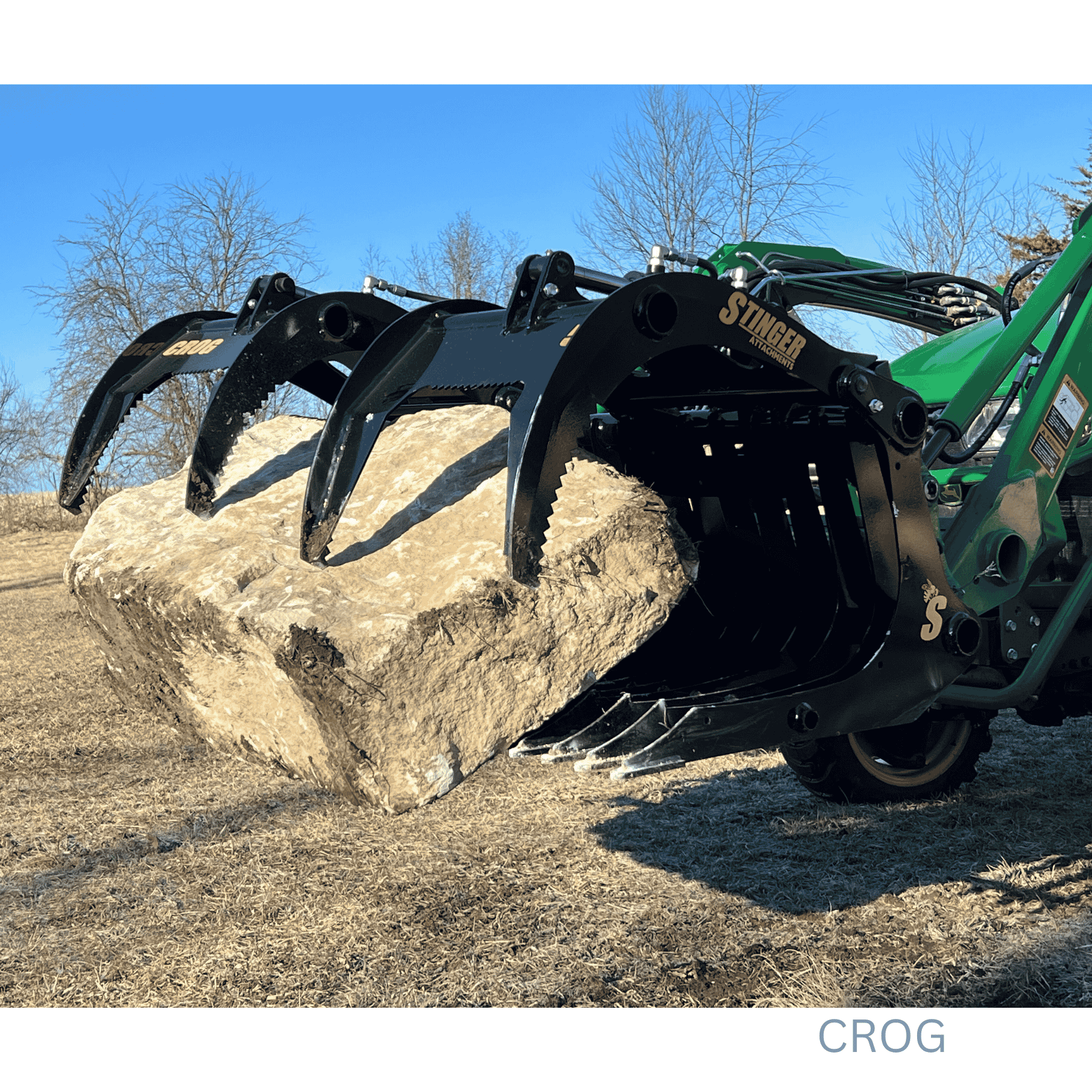

Our Clam and Root grapples feature massive jaw openings (up to 60") to maximize volume per pass when moving brush piles.

Hydraulic cylinders and hoses are fully guarded to prevent downtime from falling debris or rebar punctures during demoliti

Choosing the Right Grapple Style

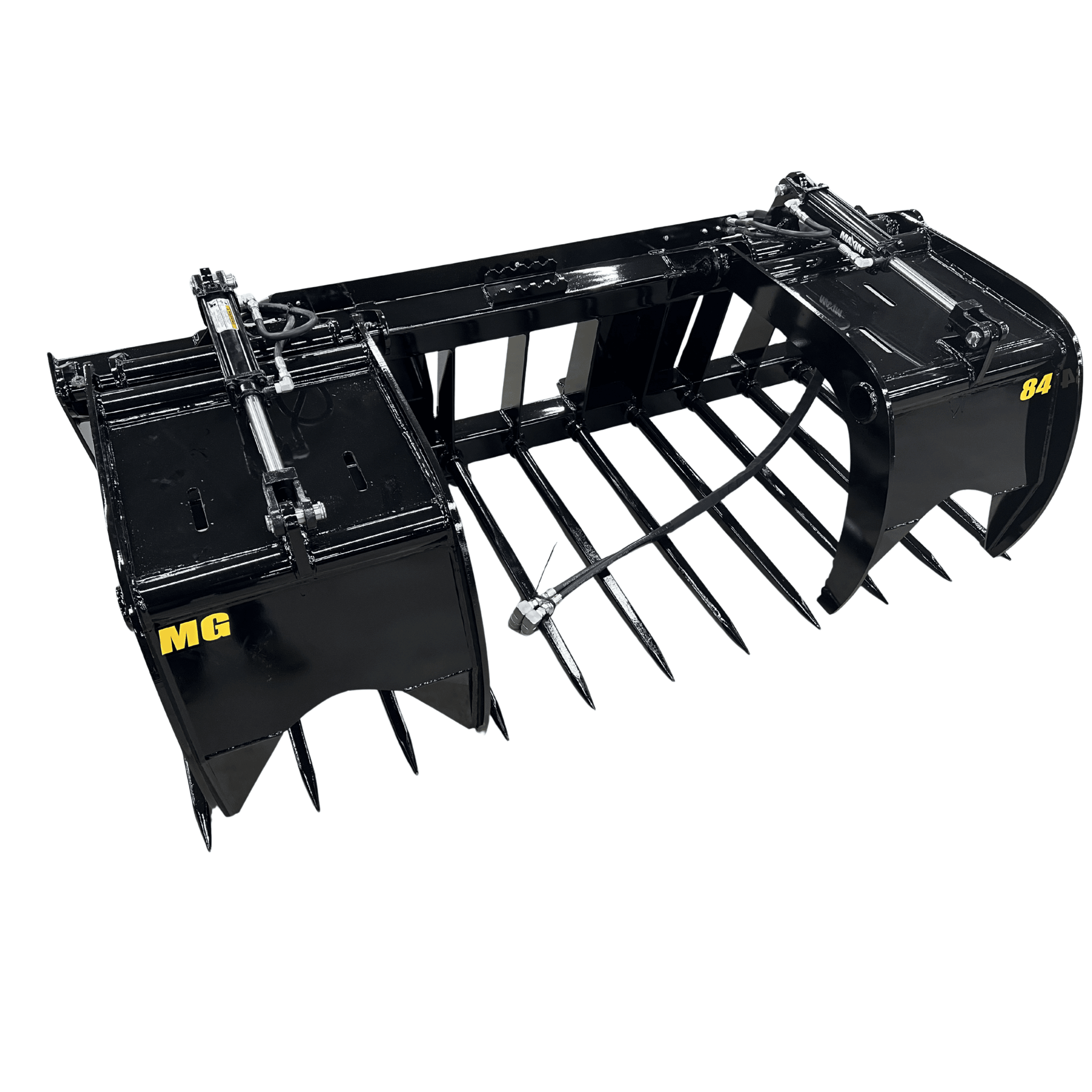

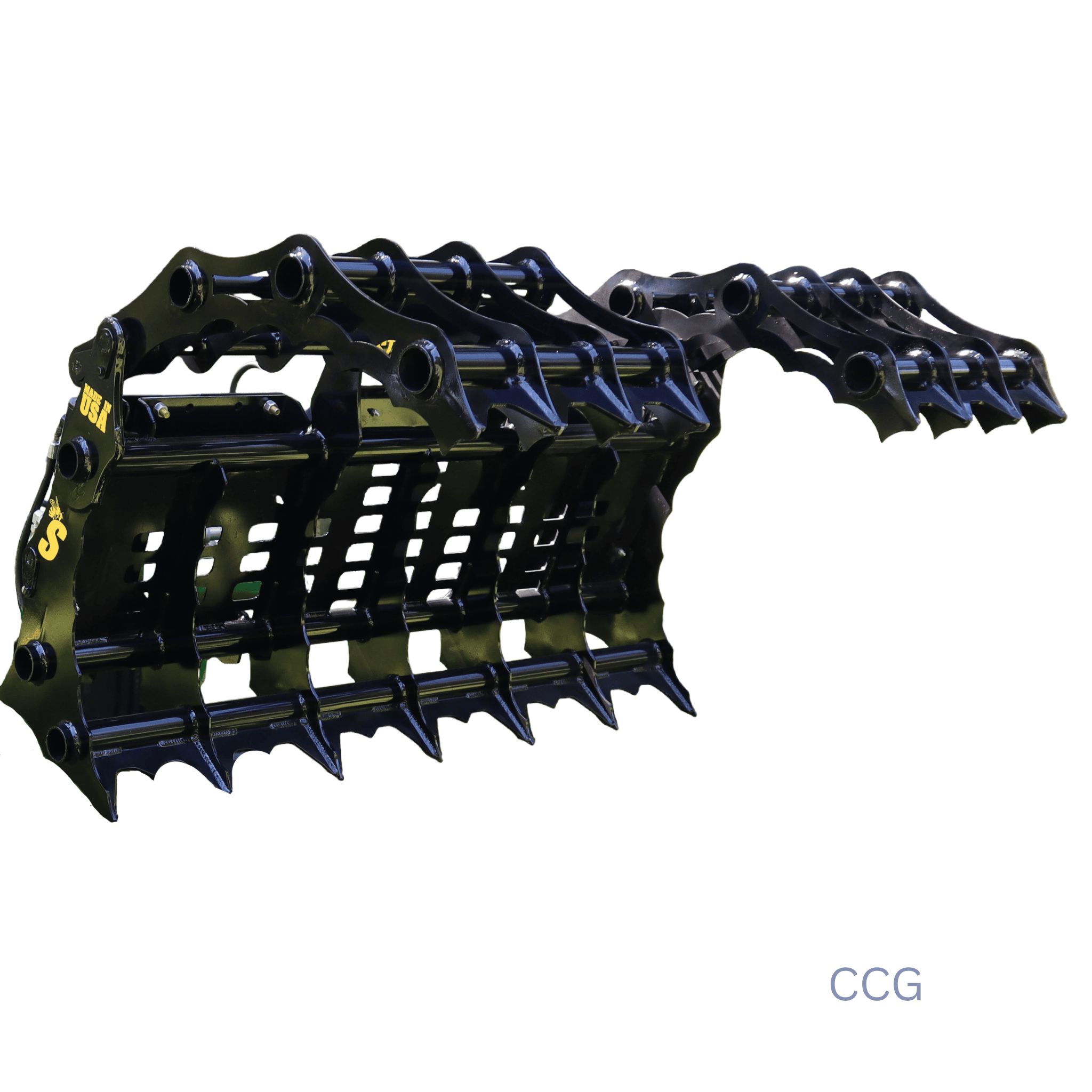

1. Root & Rock (Skeleton Style)

Best for: Land Clearing & Sifting. These grapples feature open tine spacing (typically 6"). This design allows dirt and sand to sift through the bottom while holding onto rocks, roots, and large debris. This reduces the weight of your load and keeps your topsoil on the ground where it belongs.

Models: RTG (Root), RRG (Root & Rock), RG Series.

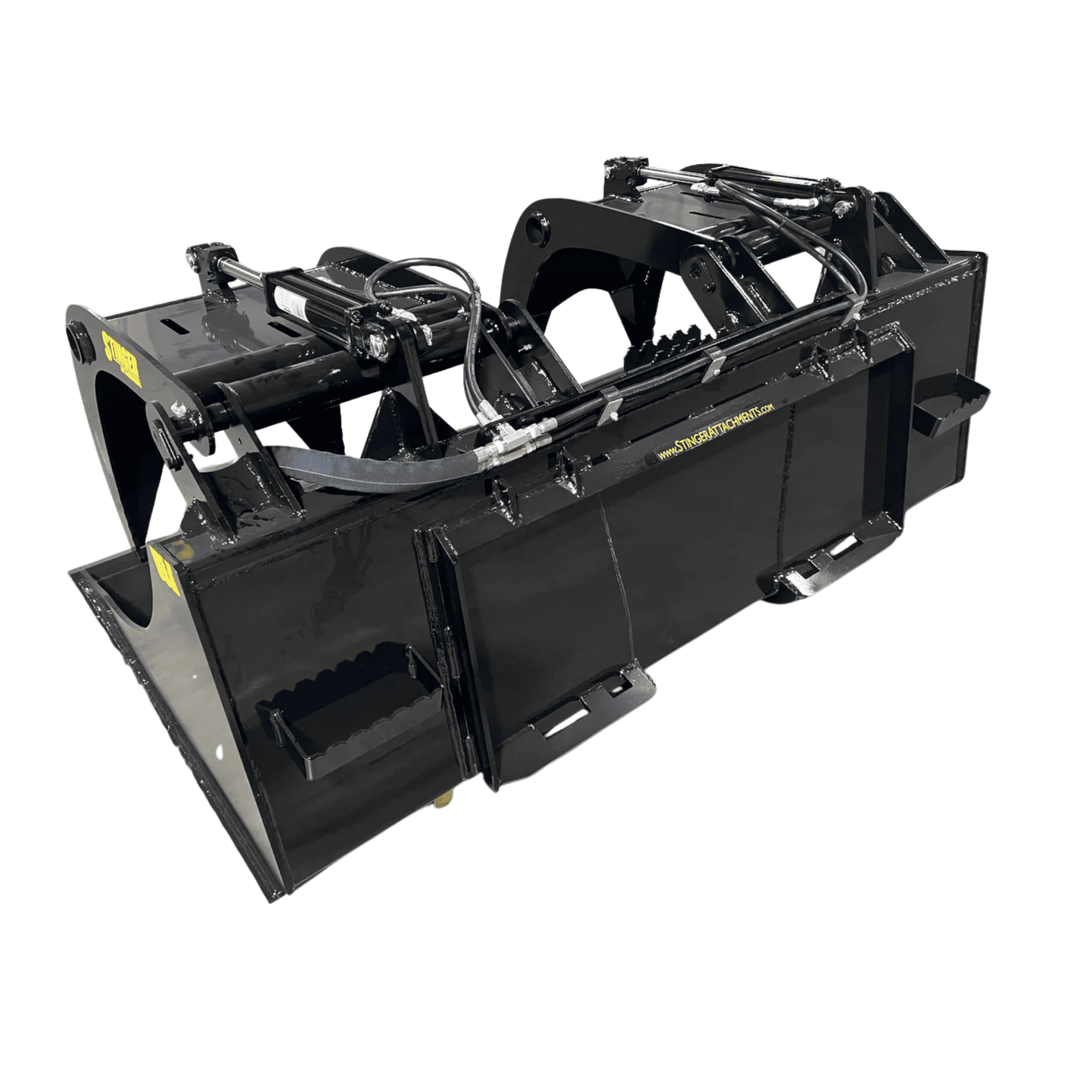

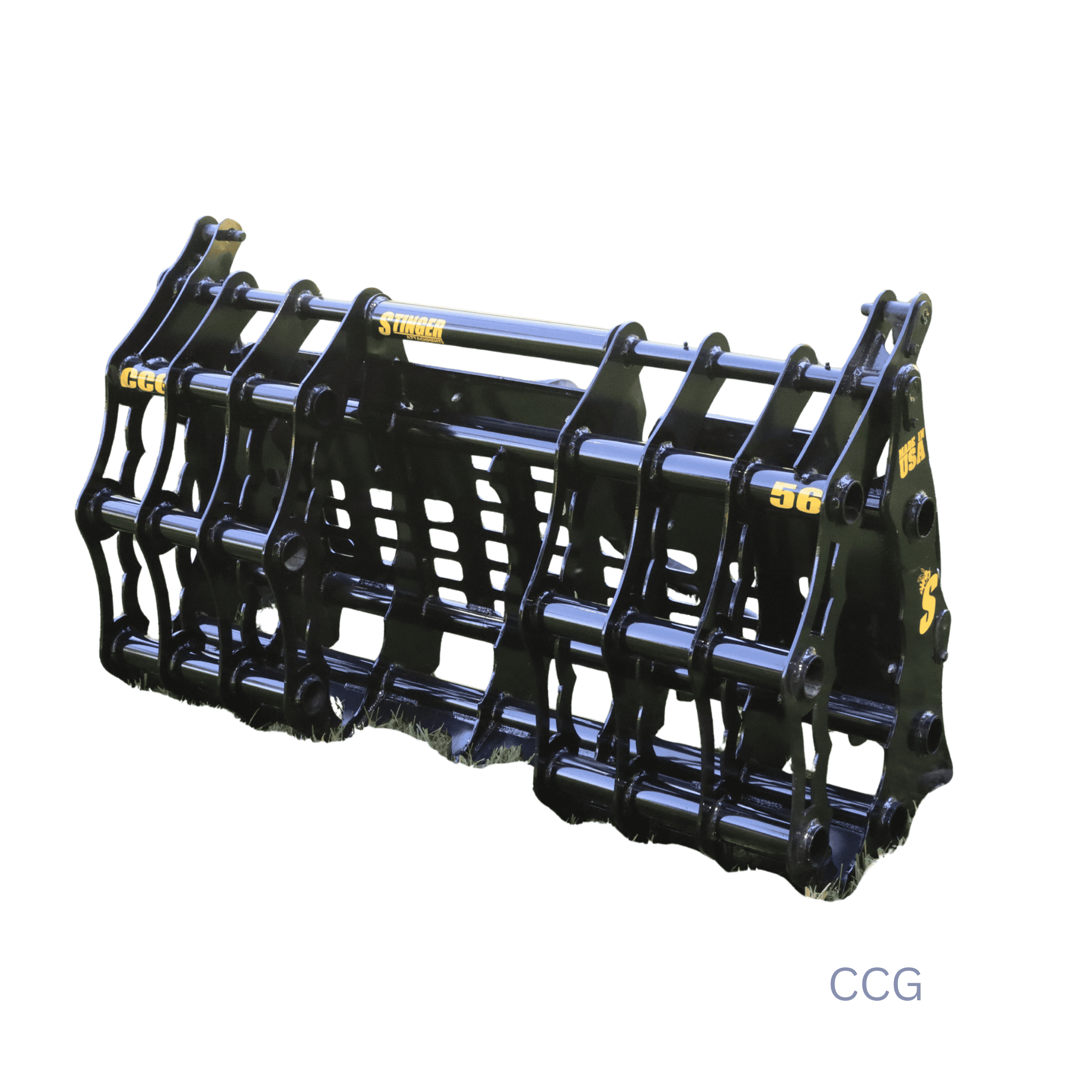

2. Scrap & Demolition (Solid Bottom)

Best for: Demolition, Trash, & Loose Material. Also known as "Grapple Buckets," these feature a solid steel floor. They are essential for cleaning up demolition sites where you need to capture small debris like bricks, shards, and gravel that would fall through a skeleton grapple.

Models: DG Demolition, ROG Open-Side.

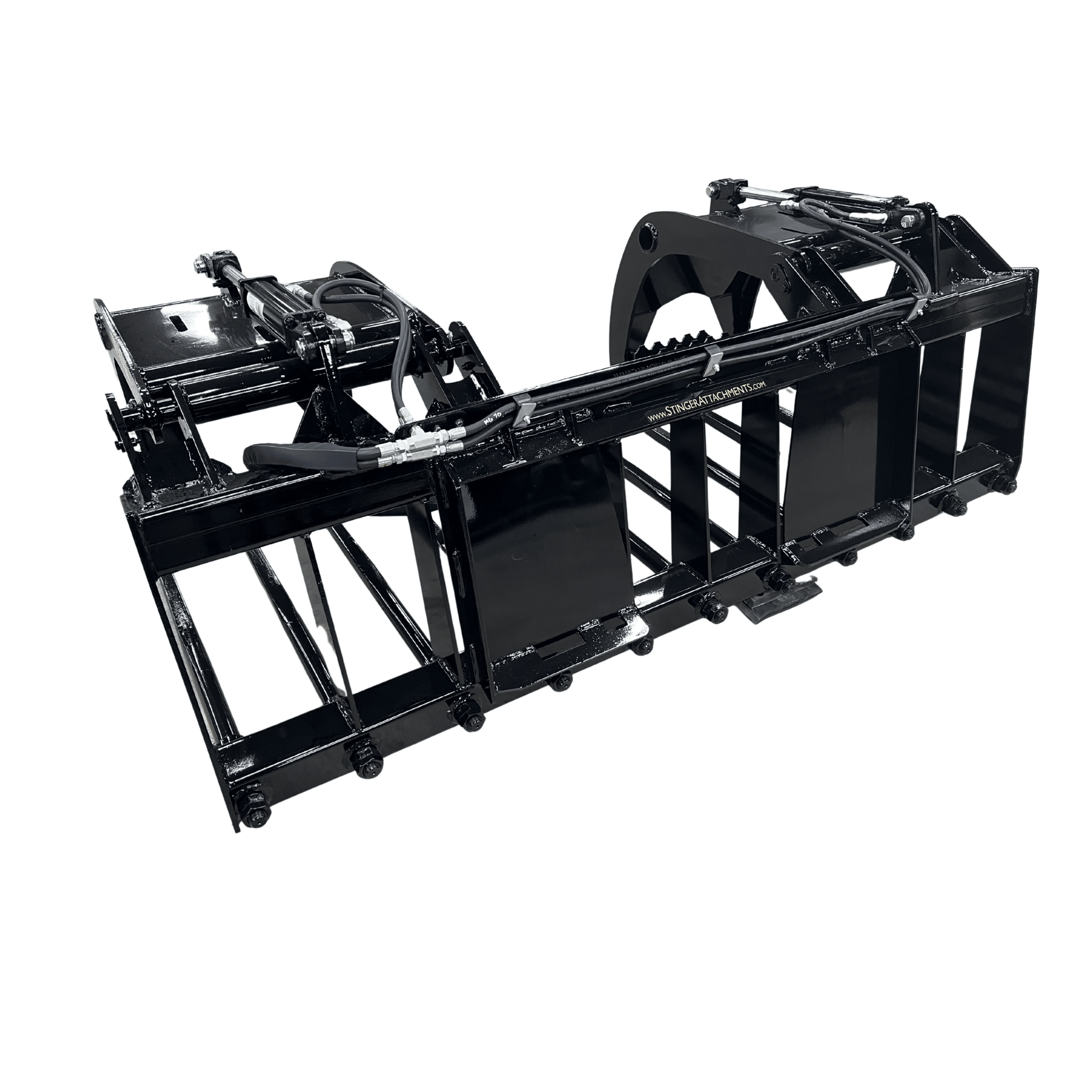

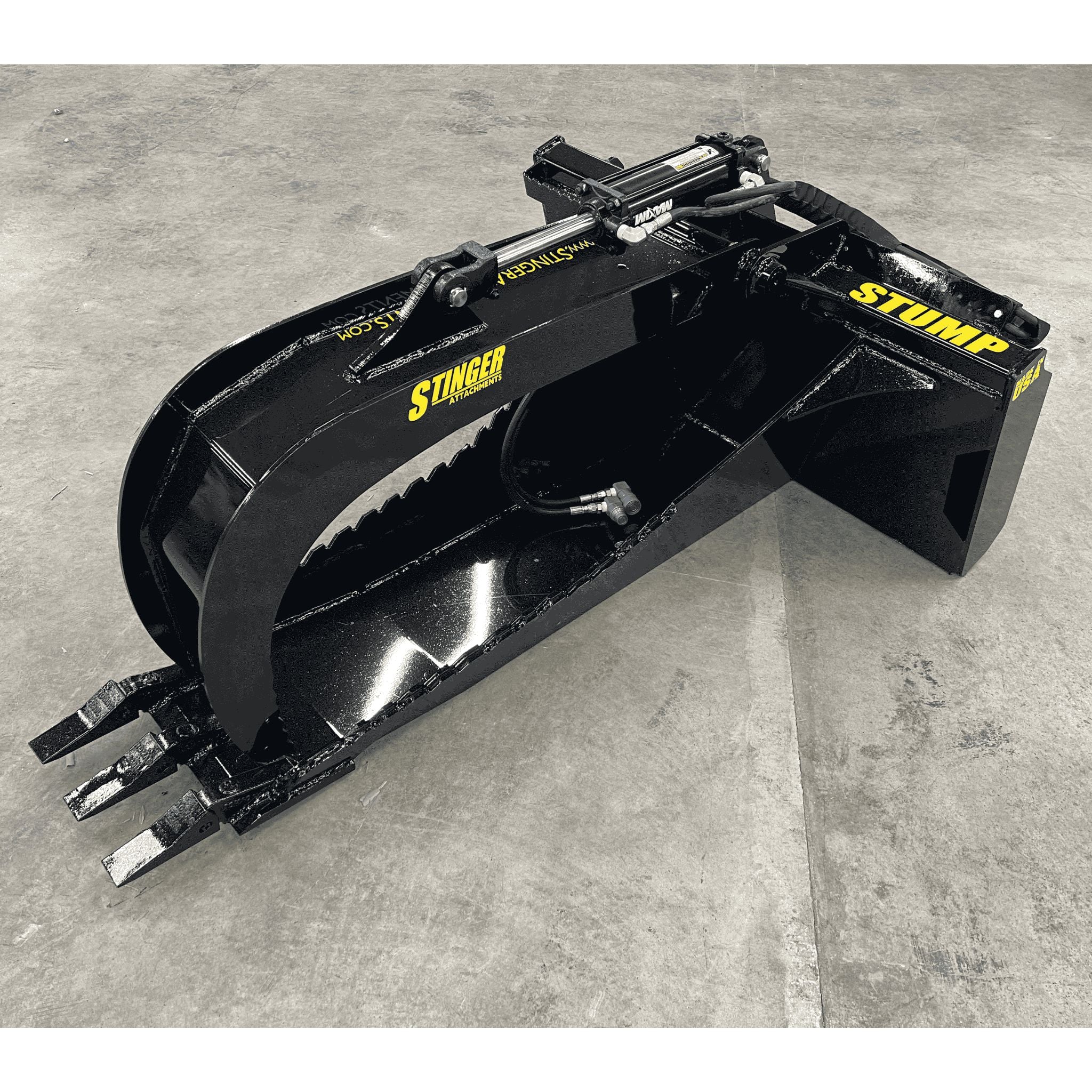

3. Forestry & Specialty

Best for: Logs, Brush & Odd Objects. For specific tasks, standard buckets don't work. The Clam Grapple acts like a hand, pinching logs and brush piles vertically. The Stump Grapple is a narrow, focused tool designed to dig and rip roots efficiently.

Cover Your Tracks: Always select a grapple width that is equal to or wider than your machine's width (measured outside of tires/tracks). This ensures you clear a path for your machine, protecting your tires from sharp debris and punctures.