Description

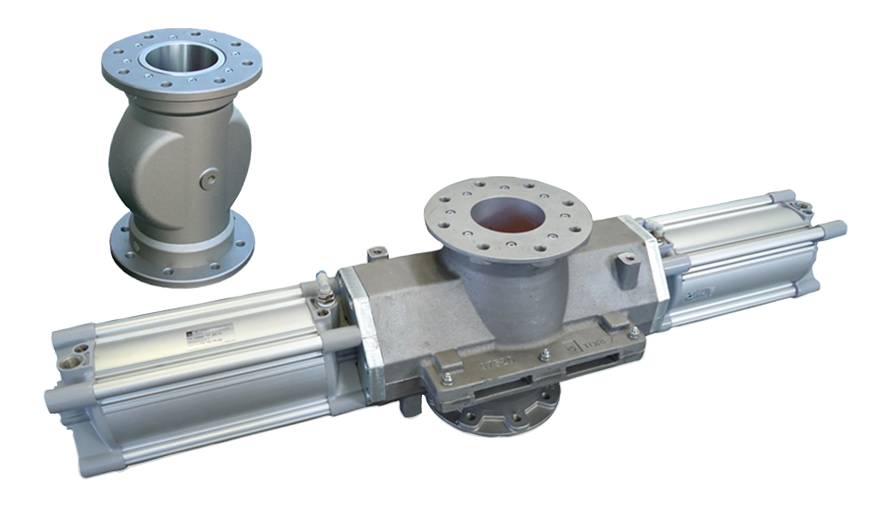

The WAM VM/VMM Series Pinch Valves are engineered to provide precise control over the flow of dry bulk materials, particularly those that are abrasive or corrosive. These valves are a crucial component in various industrial applications, including cement processing, mining, and chemical industries, where the handling of tough materials is essential.

Key Features and Functions:

-

Pinch Valve Design: The unique pinch mechanism utilizes a flexible sleeve that compresses to close the flow path. When the sleeve is released, the material is free to flow through the valve. This design is particularly effective for controlling the flow of materials that are prone to abrasion or corrosion.

-

Abrasive Material Handling: The flexible sleeve is the only part of the valve in contact with the material, making it ideal for handling abrasive substances such as cement, aggregates, and minerals. The design reduces wear and tear on other components.

-

Corrosive Material Handling: The sleeve material can be selected from various elastomers and polymers that resist corrosion, making the valve suitable for handling aggressive chemicals or other corrosive substances often found in cement processing.

-

Full Bore Opening: The valve provides a full bore opening when fully open, which reduces pressure drop and maximizes material flow, increasing operational efficiency.

-

Various Sizes and Configurations: Available in multiple sizes and configurations to cater to different material flow rates, silo capacities, and industrial application needs.

-

Manual or Actuated Operation: These valves can be manually operated or controlled by pneumatic or electric actuators for automated systems, enabling seamless integration into automated bulk material handling systems.

Applications:

-

Cement Processing: The VM/VMM valves are specifically designed to handle the tough, abrasive materials typically found in cement processing, offering controlled discharge from silos, hoppers, and bins.

-

Abrasive and Corrosive Material Handling: Suitable for applications involving abrasive materials such as cement, aggregates, lime, and fly ash, as well as corrosive chemicals and additives used in cement production.

-

Conveying System Control: These valves also regulate the flow of materials within pneumatic or mechanical conveying systems, ensuring smooth and efficient transportation of bulk materials.

Specific Relevance to Cement Silo Processing:

-

Abrasive Material Control: The pinch valve design ensures minimal wear on the valve components, even when handling highly abrasive materials like cement and aggregates. This extends the valve's lifespan and reduces maintenance needs.

-

Corrosive Additive Handling: The flexibility of the sleeve material makes it highly effective for controlling the flow of corrosive additives or chemicals used in cement production, ensuring reliable operation and longevity.

-

Silo Discharge Control: These valves are effective for managing the controlled discharge of cement and other materials from silos, ensuring a consistent and efficient flow of bulk materials.