Description

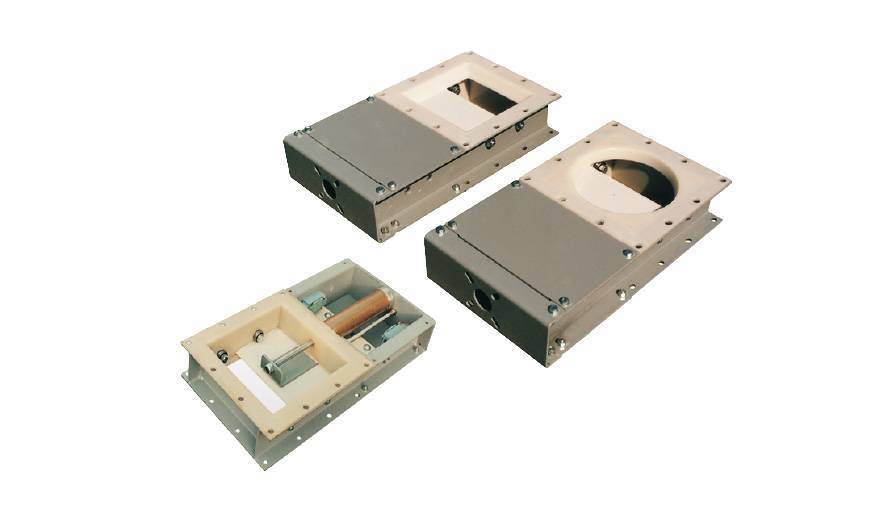

The WAM VL Series Slide Gate Valve is specifically designed to manage the controlled opening and closing of bulk materials within silos, hoppers, and storage containers. Its application spans various industries, with cement processing being a key area of use. This valve ensures precise material flow regulation, enhancing operational efficiency.

Key Features and Functions:

-

Slide Gate Design: The VL valve employs a sliding gate that moves horizontally, which allows for easy and effective regulation of material flow. This straightforward design is highly reliable for managing bulk material discharge.

-

Modular Design: The modular nature of the VL series provides flexibility in terms of configurations and customization, making it adaptable to various material handling systems and specific operational needs.

-

Robust Construction: Built to endure harsh and abrasive materials commonly found in cement processing, the VL series is constructed using durable materials that provide long-lasting performance in industrial environments.

-

Various Sizes and Configurations: These valves come in a range of sizes and configurations, enabling them to accommodate different flow rates, silo capacities, and application requirements.

-

Manual or Actuated Operation: The VL Series can be operated manually with a handwheel or lever, or automatically using pneumatic or electric actuators for integration into automated material handling systems.

-

Dust-Tight Sealing: The valve's design ensures tight sealing during operation, which helps minimize dust emissions during material discharge. This reduces environmental impact and enhances workplace safety.

Applications:

-

Cement Processing: Primarily used for managing the flow of cement, the VL Series ensures consistent and accurate discharge, enhancing the efficiency of cement silos.

-

Handling Powdery or Granular Materials: Also suitable for handling other materials like lime, fly ash, and similar bulk powders.

-

Material Discharge Control: Ensures a metered and steady flow of material during silo discharge, contributing to smoother and more controlled operations.

-

Automated Material Handling: The option for pneumatic or electric actuation allows for easy integration into fully automated systems, enhancing precision and reducing manual intervention.

Specific Relevance to Cement Silo Processing:

-

Silo Discharge Control: The VL valve is ideal for controlling cement discharge from silos, ensuring the material is discharged in a controlled and consistent manner.

-

Environmental Benefits: The dust-tight sealing minimizes dust emissions during discharge, which is critical for maintaining a safe and clean working environment, as well as reducing environmental impact.

-

Easy Installation and Maintenance: The modular construction allows for easier installation and simpler maintenance procedures, reducing downtime and associated costs.