WAM

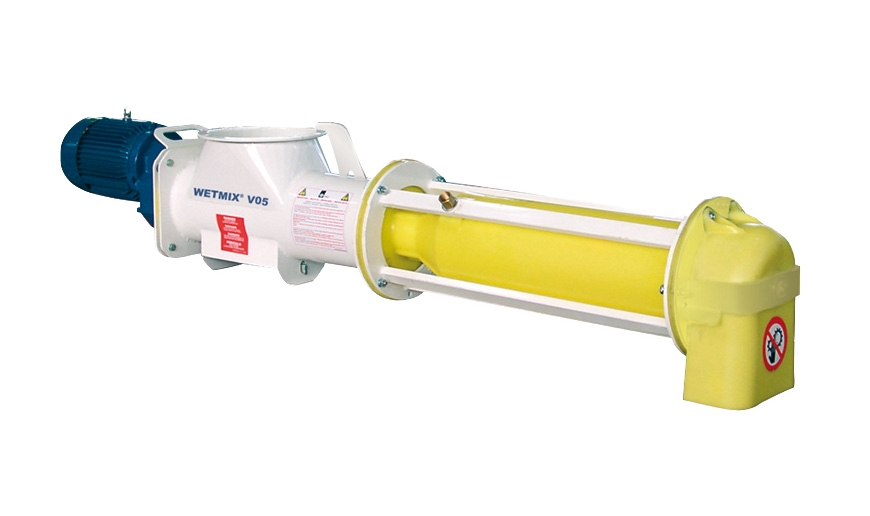

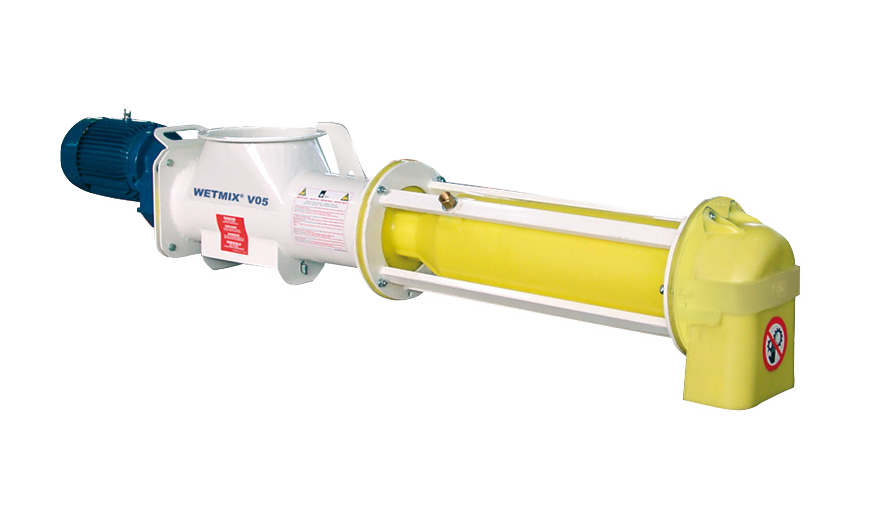

WAM WETMIX Continuous Screw Mixer (WETMIX V05)

WAM WETMIX Continuous Screw Mixer (WETMIX V05)

The WAM WETMIX V05 is a compact and efficient continuous mixer designed for preparing dry premixed mortar or concrete on construction sites. Its modular design and ease of handling make it a valuable tool for concrete production, especially in applications requiring continuous mixing and a compact footprint.

Key Features and Benefits

-

Continuous Mixing

Ensures a steady flow of fresh concrete, ideal for continuous pours like shotcrete and grouting, eliminating batch mixing delays. -

Precise Mixing Control

Accurate control over water addition ensures consistent concrete workability and minimizes variations in mix quality, improving structural integrity. -

SINT Engineering Polymer Construction

The mixing chamber and rotor are made of durable SINT engineering polymer, reducing material buildup, simplifying cleaning, and extending the mixer’s lifespan. -

Modular Design

Easy to transport, install, and integrate into existing setups, offering flexibility for various concrete production projects. -

Compact Footprint

Perfect for confined spaces and easy to move on-site, optimizing efficiency in tight areas. -

Gravity Flood-Feed System

Simple loading of dry mix from silos or hoppers, streamlining the mixing process and reducing labor. -

Self-Washing Function

The mixer features a rapid self-cleaning cycle, minimizing downtime and maintenance efforts. -

Consistent Output

Provides a continuous, reliable output of mixed material for improved productivity.

Technical Specifications

-

Mixing Capacity: 40 to 100 liters per minute (1.4 to 3.5 cfm)

-

Power Supply: Electric motor (customized voltage and power ratings available based on application)

-

Materials: SINT engineering polymer for the mixing chamber and rotor, steel frame

-

Dimensions: Contact for specific model dimensions

-

Weight: Contact for weight details based on configuration

-

Water Supply Connection: Standard hose connection

Applications in Concrete Production

-

Shotcrete: Continuous supply for spray applications.

-

Grouting: Ideal for grouting applications that need consistent quality.

-

Concrete Repair: Perfect for on-site mixing for repairs.

-

Precast Concrete Production: Continuous mixing for smaller precast elements.

-

Foundation Work: Ensures consistent pouring for large foundations.

-

Slab Construction: Continuous supply of concrete for large slab pours.

Operational Considerations

-

Material Compatibility: Ensure compatibility with concrete mixes.

-

Water Control: Precise water addition is essential for optimal workability.

-

Maintenance: Regular cleaning and upkeep will ensure longevity and performance.

-

Safety: Follow safety guidelines for handling electrical equipment and mixing materials.

Important Notes

-

Consult the official WAMGROUP documentation for the most accurate and up-to-date specifications.

-

Ensure the correct water-to-cement ratio to achieve the desired mix quality.

-

For detailed configuration and product recommendations, please reach out to your local distributor.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...