WAM

WAM VW Series Diverter Valve

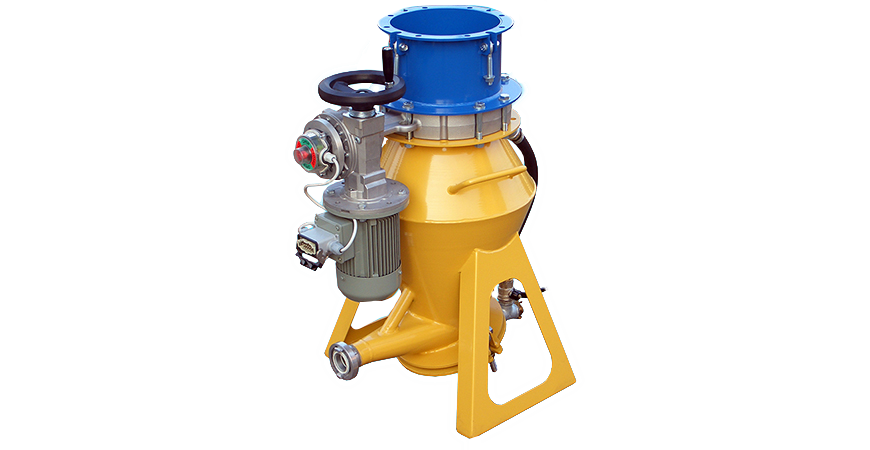

WAM VW Series Diverter Valve

The WAM VW Series Diverter Valve is designed to manage and redirect the flow of dry bulk materials, particularly in pneumatic conveying systems. It is widely used in industries such as cement processing, where materials need to be routed to different destinations within the production process. This valve plays a crucial role in improving efficiency by controlling material flow to different silos, hoppers, or processing equipment.

Key Features and Functions:

-

Diverter Valve Design: The valve features a rotating diverter mechanism that directs the flow of material to one of multiple outlets. This allows for precise control over the material's destination within the system.

-

Pneumatic Conveying: Specifically designed for use in pneumatic conveying systems, the VW valve efficiently manages the flow of materials that are transported using air pressure, making it ideal for powdery or granular substances.

-

Robust Construction: Built from durable materials, the VW series valve is capable of withstanding abrasive and challenging environments, making it suitable for industries like cement processing.

-

Various Sizes and Configurations: The VW series is available in different sizes and configurations to accommodate various flow rates and system requirements.

-

Manual or Actuated Operation: The valve can be manually operated or equipped with pneumatic or electric actuators, offering flexibility and integration into automated control systems for better control and efficiency.

Applications:

-

Cement, Lime, and Fly Ash Handling: The VW series valve is primarily used to divert cement, lime, fly ash, and other powdery or granular materials in pneumatic conveying systems.

-

Material Routing: It helps route materials to different destinations within a plant, such as silos, hoppers, or processing equipment, enhancing the flexibility of material handling systems.

Specific Relevance to Cement Silo Processing:

-

Efficient Material Routing: The VW valve is crucial for directing cement or other materials to different silos or processing equipment, allowing for optimized routing in a cement plant or concrete batching plant.

-

Flexible System Design: The valve’s versatile design enables a flexible system layout, ensuring that material handling and routing are carried out efficiently.

-

Automated Control: The option for actuated operation ensures that the valve can be integrated into automated control systems, offering precise and reliable material routing based on real-time system requirements.

-

Dust Reduction: With its enclosed design, the VW valve helps minimize dust emissions during material diversion, improving working conditions and reducing environmental impact.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...