WAM

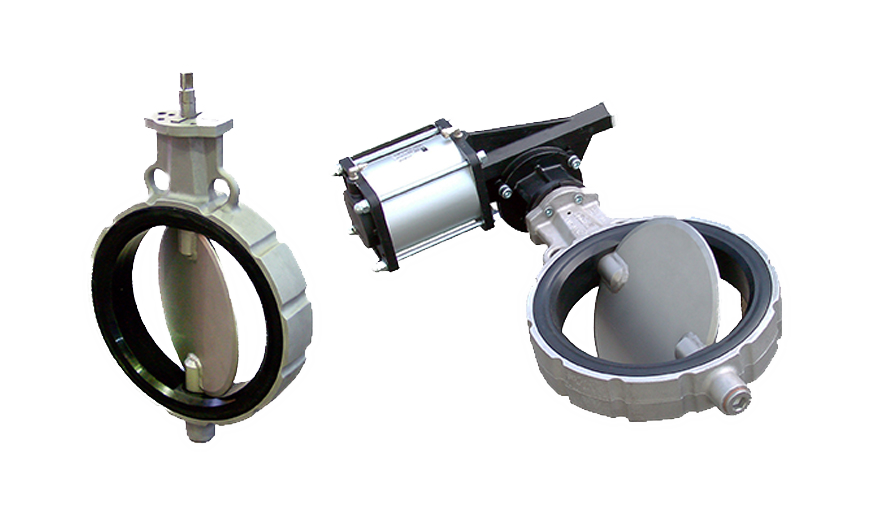

WAM VW Series Butterfly Valves

WAM VW Series Butterfly Valves

The WAM VW Series Butterfly Valve is designed to effectively control the flow of dry bulk materials, especially in pneumatic conveying systems. These valves are particularly useful in industries that handle powdery or granular materials, including cement processing. They provide precise control and efficient operation in material transport systems.

Key Features and Functions:

-

Butterfly Valve Design: The valve features a rotating disc inside a circular opening to control the flow of material. This design allows for quick and precise regulation of material flow.

-

Pneumatic Conveying Systems: The VW butterfly valves are specifically designed for pneumatic conveying systems, where materials are transported through pipelines using air pressure.

-

Robust Construction: These valves are built with durable materials to endure the wear and tear from abrasive materials commonly found in industrial environments like cement processing.

-

Various Sizes and Configurations: Available in multiple sizes and configurations, the VW butterfly valves can be tailored to meet different flow rates and system requirements.

-

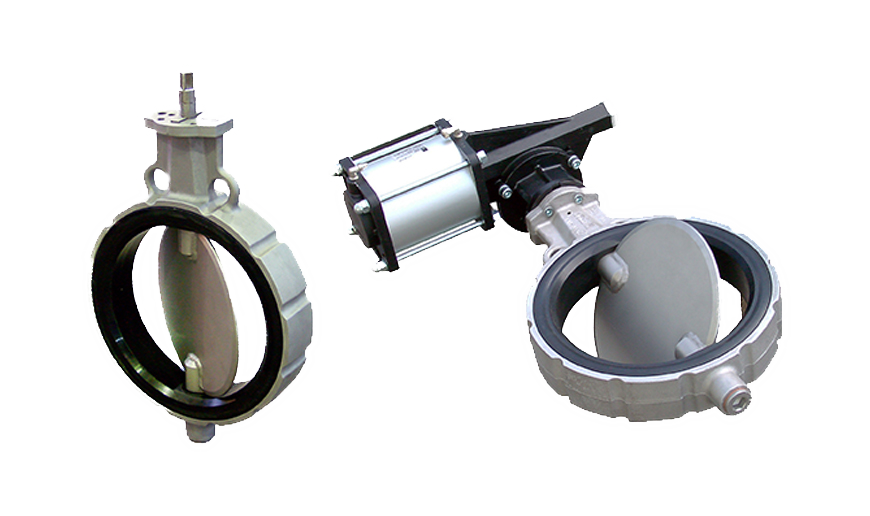

Manual or Actuated Operation: VW valves can be operated manually or automatically through pneumatic or electric actuators, providing flexibility for integration into automated systems.

Applications:

-

Cement, Lime, Fly Ash Handling: The VW butterfly valve is commonly used in controlling the flow of materials like cement, lime, and fly ash, as well as other powdery or granular substances in pneumatic conveying systems.

-

Flow Control in Pneumatic Conveying Systems: The valves ensure the controlled and reliable flow of materials within the pneumatic conveying system, a critical function for maintaining system efficiency and preventing material blockages.

Specific Relevance to Cement Silo Processing:

-

Material Flow Control: The VW valves are integral in controlling the flow of cement or other materials within the pneumatic conveying systems, providing precise regulation over material transport and distribution.

-

Dust Reduction: The enclosed design of the VW butterfly valves helps minimize dust emissions, contributing to a cleaner work environment and reducing environmental impact.

-

Automated Control Integration: The option for actuated operation allows these valves to be integrated into automated control systems, ensuring accurate and reliable material handling with minimal human intervention.

-

Efficient Material Transport: By providing consistent and controlled material flow, these valves help ensure efficient and effective transport of materials throughout the system.

The WAM VW Series Butterfly Valves are a dependable and efficient solution for controlling the flow of dry bulk materials in pneumatic conveying systems, especially in cement silo processing and other industries dealing with granular and powdery materials. Their robust design, flexibility, and dust-reducing features make them a valuable component in material handling systems.

Would you like to explore more about WAM products or other equipment used in cement silo processing?

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...