WAM

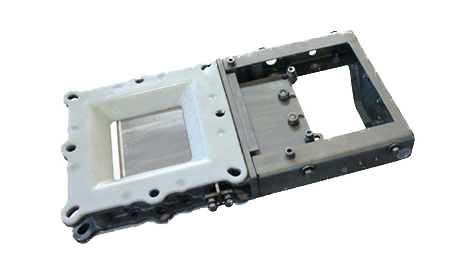

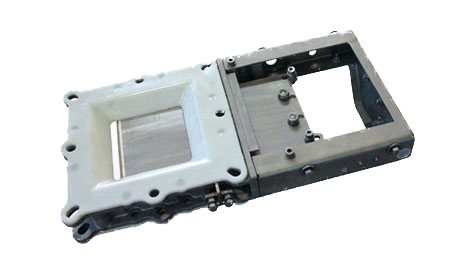

WAM VIB Series Slide Gate Valve

WAM VIB Series Slide Gate Valve

The WAM VIB Series Slide Gate Valve is designed to control the flow of bulk materials in silos, hoppers, and other storage containers. It is commonly used in industries like cement processing, where precise material handling and flow control are crucial for operational efficiency. The valve utilizes a sliding gate mechanism to regulate the discharge of materials, ensuring smooth, controlled operations.

Key Features and Functions:

-

Slide Gate Design: The valve features a sliding gate that moves horizontally to open and close the flow of material, offering simple yet effective regulation of bulk material discharge.

-

Robust Construction: The VIB valves are built from durable materials that can withstand harsh conditions, including abrasive materials commonly found in industrial environments.

-

Various Sizes and Configurations: Available in a wide range of sizes and configurations to accommodate different flow rates, silo capacities, and specific application requirements.

-

Manual or Actuated Operation: These valves can be operated manually using a handwheel or lever, or can be automated with pneumatic or electric actuators, offering flexibility and integration into automated systems for precise control.

Applications:

The WAM VIB Series Slide Gate Valve is used for handling a variety of powdery or granular materials, including cement, lime, and fly ash. It is ideal for controlling material flow during silo discharge, batching, and material transfer operations in various industries.

Specific Relevance to Cement Silo Processing:

-

Silo Discharge Control: The VIB valve is particularly useful in controlling the discharge of cement from silos, ensuring a consistent and metered flow to prevent overloading or underfeeding.

-

Dust-Tight Sealing: The valve’s design and high-quality sealing materials help minimize dust emissions during material discharge, improving working conditions and reducing the environmental impact of cement processing.

-

Easy Installation and Maintenance: The modular design of the VIB valve, combined with its robust construction, makes it easy to install and maintain, minimizing downtime and maintenance costs.

-

Automated Control: The valve’s actuated operation option allows for seamless integration into automated control systems, enabling precise material handling and improving operational efficiency.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...