WAM

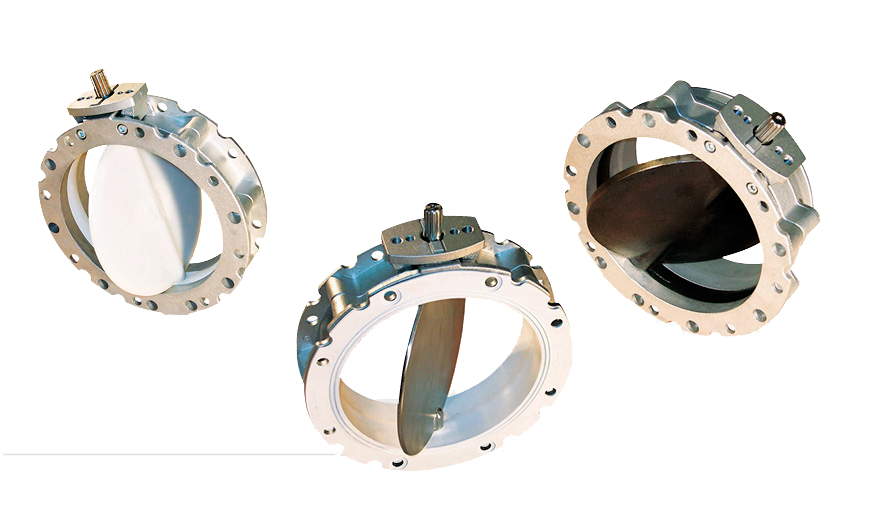

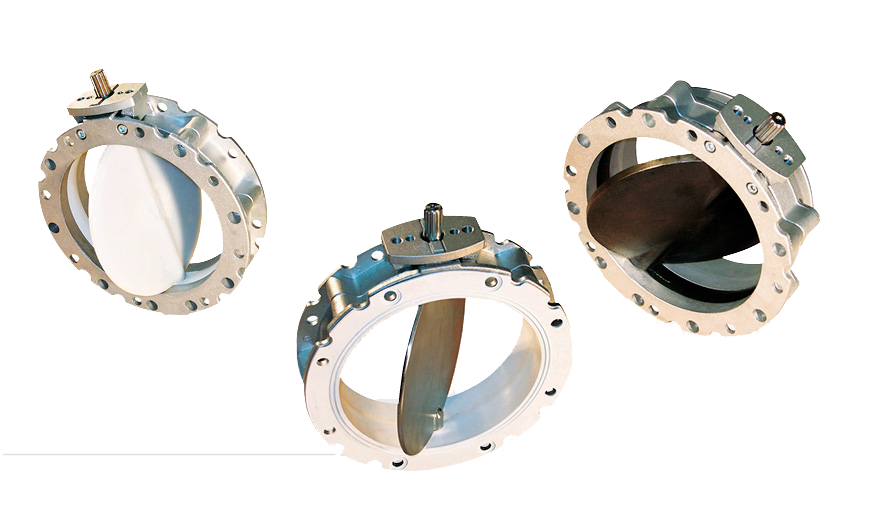

WAM VFS Series Butterfly Valve

WAM VFS Series Butterfly Valve

The WAM VFS Series Butterfly Valve is a versatile and durable valve designed for controlling the flow of dry bulk materials from silos, hoppers, bins, or other storage containers. It is commonly used across various industries, particularly in cement processing, to efficiently regulate the discharge of materials.

Key Features and Functions:

-

Butterfly Valve Design: The valve features a disc-shaped design that rotates within a circular opening to control the material flow. This simple yet efficient mechanism offers smooth and reliable operation.

-

Modular Design: The VFS series employs a modular design, enabling flexibility for different configurations and customizations tailored to specific application needs.

-

Robust Construction: Built with durable materials such as cast iron or aluminum, the valve can endure the demanding conditions of industrial environments, ensuring long-lasting performance.

-

Various Sizes and Configurations: The valve is available in different sizes and configurations, allowing it to accommodate varying flow rates and installation requirements.

-

Manual or Actuated Operation: The VFS series can be operated manually or with pneumatic or electric actuators, offering automation for enhanced material handling control.

Applications:

The WAM VFS Series Butterfly Valve is primarily used for controlling the discharge of materials such as cement, lime, fly ash, and other powdery or granular materials from silos, hoppers, and bins. It helps in ensuring smooth and precise material flow during industrial operations.

Specific Relevance to Cement Silo Processing:

-

Silo Discharge Control: The VFS valve is crucial for controlling the flow of cement from silos, ensuring a consistent and metered discharge of material to downstream systems.

-

Dust-Tight Sealing: The design and sealing materials used in the VFS valve minimize dust emissions during material discharge, enhancing safety and reducing environmental impact.

-

Easy Installation and Maintenance: The modular design allows for straightforward installation and maintenance, ensuring minimal downtime and ease of service.

-

Automated Control: With the option for actuated operation, the valve can be integrated into automated control systems, enabling precise and reliable material handling.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...