WAM

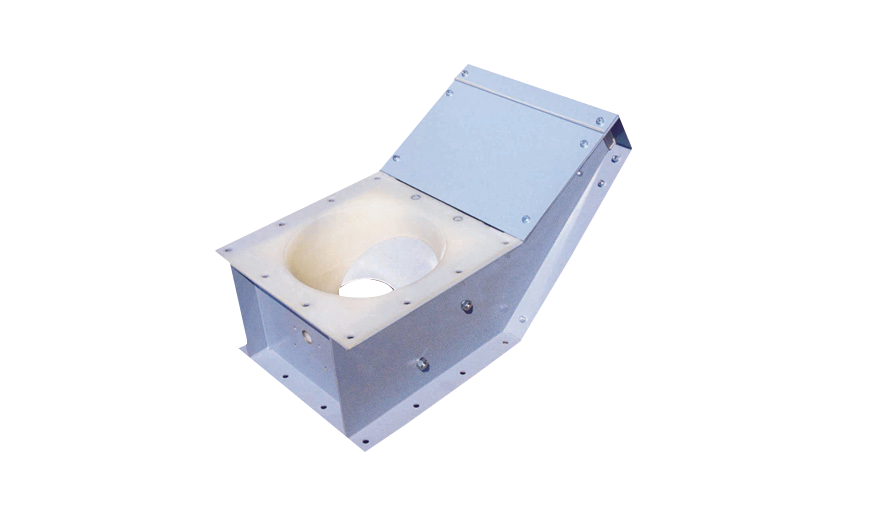

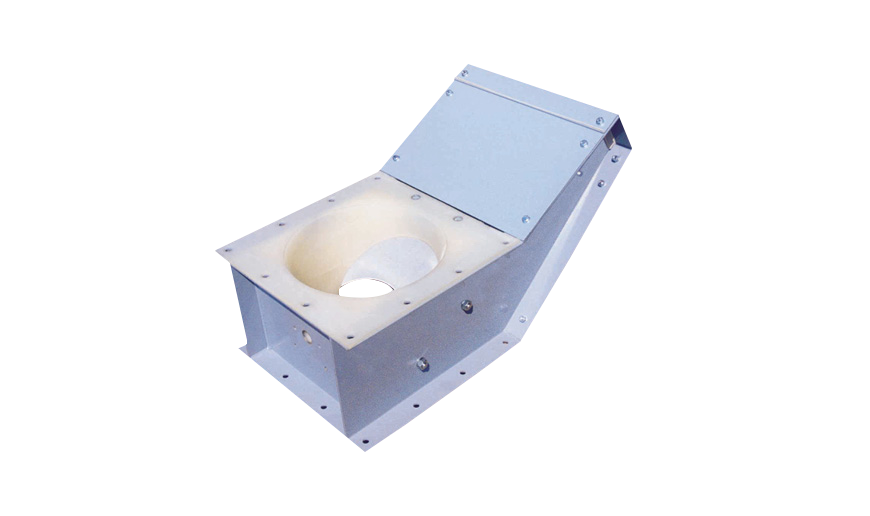

WAM VDI Series Inclined Feeder Valve

WAM VDI Series Inclined Feeder Valve

The WAM VDI Series Inclined Feeder Valve is designed for the controlled discharge and feeding of powdery or granular materials from silos, hoppers, or other storage containers. This valve is particularly useful in industries handling bulk solids, such as cement processing, where the space constraints or specific material flow requirements require an angled discharge. The inclined design provides a space-saving and efficient solution for material handling systems.

Key Features and Functions:

-

Inclined Design: The valve features an inclined body, which allows for angled discharge of materials. This feature is especially advantageous when a vertical discharge is not suitable or when space constraints require a different discharge angle.

-

Controlled Material Discharge: The valve regulates the material flow, ensuring a consistent, metered discharge rate. This feature is important for maintaining precise control over material handling operations.

-

Robust Construction: The VDI valves are built with durable, high-quality materials to withstand abrasive materials and harsh industrial environments, ensuring long-lasting and reliable performance.

-

Various Sizes and Configurations: Available in a variety of sizes and configurations to accommodate different flow rates and application requirements, the VDI valve is highly versatile.

-

Applications: Primarily used for handling bulk materials such as cement, lime, fly ash, and other powdery or granular substances, which are often encountered in industries like cement manufacturing.

Applications:

-

Material Discharge Control: The VDI valve is used to regulate and control the discharge of cement, lime, and other bulk solids from silos and hoppers, ensuring accurate and consistent material flow.

-

Feeding into Conveying Systems: The valve is ideal for feeding materials into screw conveyors, pneumatic conveying systems, or other transport equipment, particularly when an inclined discharge is needed.

Specific Relevance to Cement Silo Processing:

-

Silo Discharge Control: The VDI valve ensures that cement or other granular materials are discharged from silos in a controlled manner, improving batching accuracy and operational consistency.

-

Feeding into Conveying Systems: When an angled feed is required, the VDI valve is used to feed materials into screw conveyors or pneumatic conveying systems, which helps to optimize material flow and transport.

-

Batching Accuracy: By providing a controlled material flow, the VDI valve contributes to more accurate weighing and batching in concrete production, ensuring consistency in the final product.

-

Material Handling Efficiency: The VDI valve improves material handling efficiency, particularly in situations where space limitations or the need for an inclined discharge dictate its use, enhancing overall system performance.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...