WAM

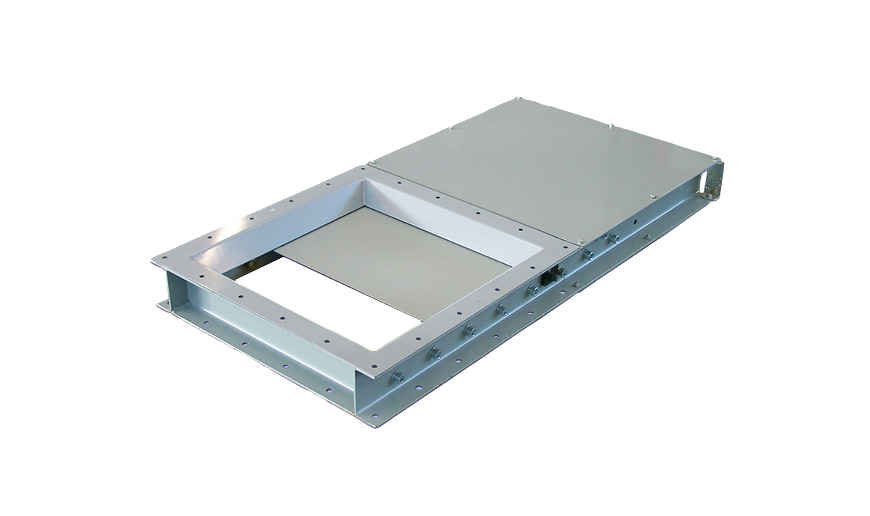

WAM Slide Gate Valve

WAM Slide Gate Valve

WAM Slide Gate Valves are industrial valves specifically designed for regulating the flow of dry bulk solids in gravity or pneumatic conveying systems. These valves are widely used across various industries, including cement, construction, plastics, food, and animal feed processing.

Key Features and Characteristics:

-

Sliding Gate Mechanism: The valve features a sliding gate or blade that moves across the flow path, allowing it to open or close the passage. This straightforward design is efficient for controlling material flow.

-

Robust Construction: WAM Slide Gate Valves are typically made from durable materials like carbon steel or stainless steel, making them suitable for abrasive and demanding industrial environments.

-

Various Sizes and Configurations: Available in a range of sizes and configurations, WAM Slide Gate Valves can be tailored to fit specific application needs and pipe sizes.

-

Manual or Actuated Operation: These valves can be operated manually using a handwheel or lever, or automated with pneumatic or electric actuators, offering flexibility in operation.

-

Tight Sealing: The design ensures a tight seal when closed, preventing material leakage and promoting efficient flow control.

-

Easy Installation and Maintenance: The valves are designed for quick and easy installation and require minimal maintenance, reducing operational downtime and costs.

Applications in Cement Silo Processing:

In cement silo processing, the WAM Slide Gate Valve plays an important role in several areas:

-

Discharge Control: The valve regulates the flow of cement from silos into trucks, mixers, or other processing equipment, ensuring efficient material handling.

-

Material Isolation: It is also used for isolating specific sections of the conveying system for maintenance or repair without disrupting the overall system.

-

Batching and Weighing: The valve helps control the flow of cement, contributing to accurate batching and weighing during the mixing process.

-

Dust Control: The tight sealing mechanism helps prevent dust emissions during material transfer, enhancing safety and environmental conditions.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...