WAM

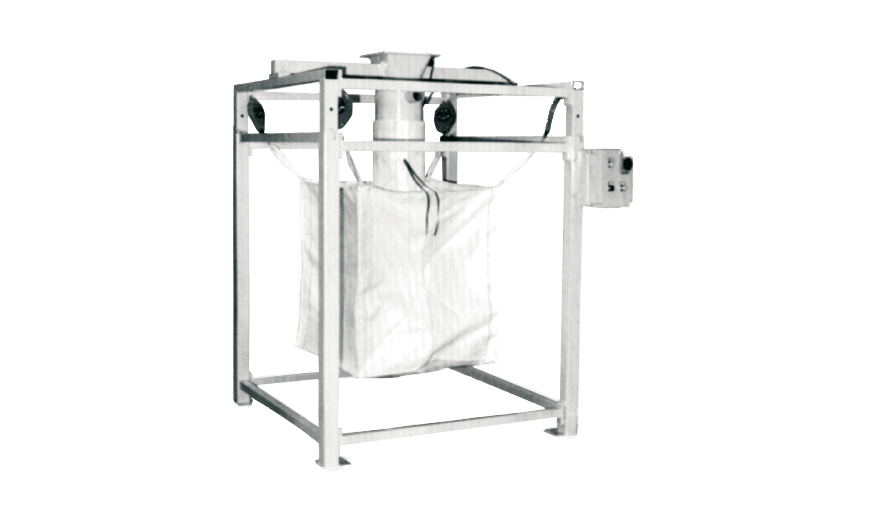

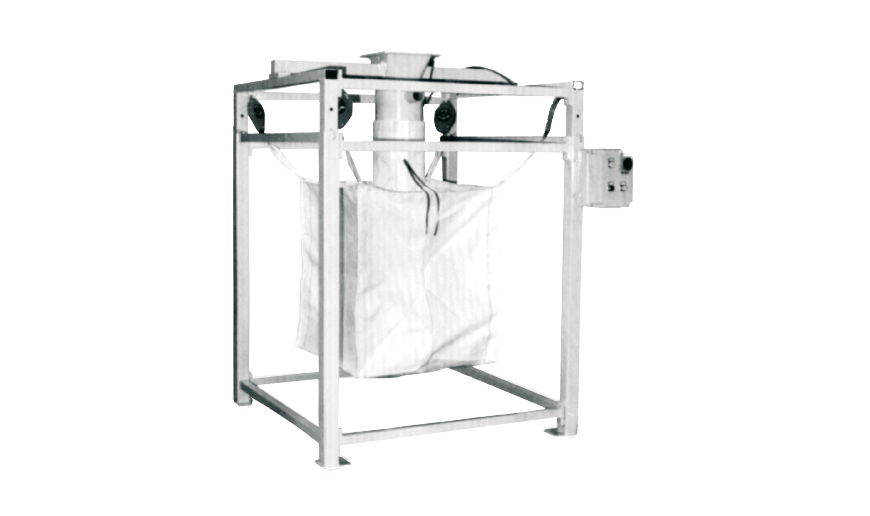

WAM RBB FIBC Filling System

WAM RBB FIBC Filling System

The WAM RBB FIBC Filling System is designed for the efficient, accurate, and dust-free filling of large bags, also known as FIBCs or "big bags," with dry, powdery, or granular materials commonly used in concrete production. This system ensures precise handling of bulk materials such as cement, fly ash, aggregates, and additives, optimizing the filling process and minimizing material loss.

Key Features and Benefits in Concrete Production:

-

Accurate Weighing:

The RBB system integrates precise weighing systems to ensure that FIBCs are filled with the exact amount of material, which is vital for maintaining consistent concrete mix proportions. -

Dust-Free Operation:

Designed to minimize dust emissions during the filling process, the RBB system helps maintain a cleaner and safer working environment in concrete plants, which is essential for regulatory compliance and worker health. -

Efficient Filling:

The system enables rapid and efficient filling of FIBCs, significantly reducing loading times and enhancing overall productivity in concrete production facilities. -

Material Waste Reduction:

By ensuring accurate weighing and minimizing dust loss, the RBB system contributes to material waste reduction, optimizing resource use and reducing operational costs. -

Versatility:

The RBB FIBC Filling System is highly versatile, capable of handling a wide variety of FIBC sizes and materials, including cement, fly ash, aggregates, and various additives used in concrete production. -

Safety:

Built with robust safety features, the system protects operators and minimizes the risk of accidents during operation, ensuring a safe working environment in the concrete plant.

Applications in Concrete Production:

-

Filling FIBCs with Cement:

Ideal for storing and transporting bulk cement in FIBCs for easy transfer to concrete batching plants. -

Filling FIBCs with Fly Ash:

Efficiently handles fly ash, a supplementary cementitious material, in FIBCs for effective storage and transport to concrete production facilities. -

Filling FIBCs with Aggregates:

The system facilitates the storage and transportation of fine aggregates (sand) or coarse aggregates (gravel or crushed stone) in FIBCs for convenient transfer to batching plants. -

Filling FIBCs with Additives:

Used to handle dry additives like pigments, fibers, or chemical admixtures in FIBCs, ensuring their safe and efficient storage and use in concrete production.

The WAM RBB FIBC Filling System is an essential solution for bulk material handling in concrete production, offering precise, efficient, and dust-free filling of large containers. By optimizing material management and minimizing waste, this system enhances the efficiency and sustainability of concrete production operations.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...