WAM

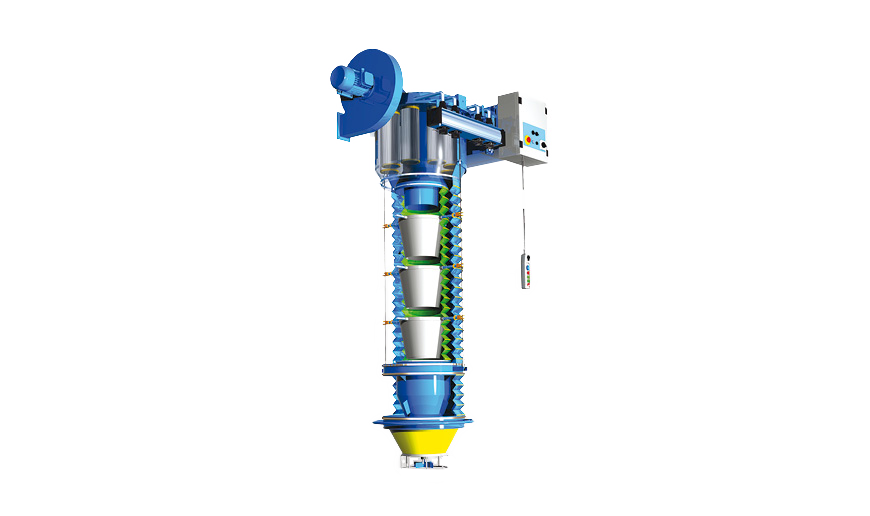

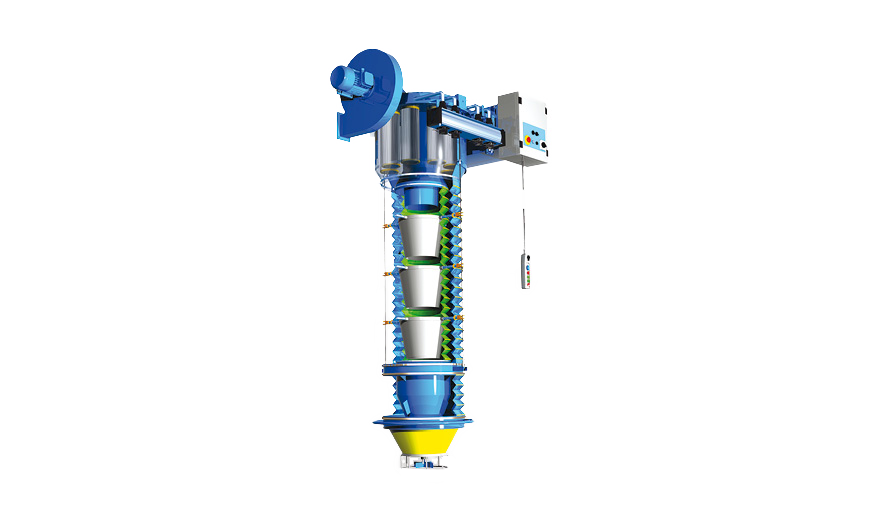

WAM Telescopic Loading Spout ZA

WAM Telescopic Loading Spout ZA

WAM Telescopic Loading Spout ZA

Description (Relevant to Concrete Production):

The WAM Telescopic Loading Spout ZA is engineered for the dust-free loading of dry, powdery materials into open trucks or railcars at concrete production facilities. This spout is a vital component for ensuring a clean, efficient, and environmentally responsible material handling process during the transfer of bulk materials such as cement, fly ash, and aggregates.

Key Features and Benefits in Concrete Production:

-

Dust-Free Loading:

The telescopic design and built-in dust collection system efficiently contain dust generated during loading, promoting a safer and cleaner working environment. This is crucial in concrete plants where large volumes of dry materials are handled. -

Precise Material Placement:

The telescopic action allows for accurate positioning of the spout within the truck or railcar, ensuring even material distribution and minimizing spillage. This helps improve loading efficiency while reducing waste. -

Efficient Loading Operation:

The ZA spout is designed for high-speed loading, reducing truck turnaround times and optimizing the overall productivity of concrete production processes. -

Material Waste Reduction:

By minimizing dust and spillage, the ZA spout contributes to significant reductions in material waste, offering both cost savings and better resource utilization in concrete production. -

Environmental Compliance:

With its dust-free operation, the ZA spout helps concrete plants meet stringent environmental regulations related to dust emissions, ensuring sustainable and eco-friendly operations. -

Adaptability:

The ZA spout is versatile and can be adapted to various truck and railcar sizes and loading requirements, making it an ideal solution for different loading needs in concrete production facilities. -

Durability:

Built with robust materials, the ZA spout is designed to withstand the abrasive nature of concrete ingredients, ensuring long-lasting performance even in the harsh conditions of concrete plants.

Applications in Concrete Production:

-

Loading Cement:

Efficiently filling trucks with bulk cement from silos for transport to construction sites or batching plants. -

Loading Fly Ash:

Handling fly ash, a common cement replacement byproduct of coal combustion, for transport or storage. -

Loading Aggregates:

Facilitating the loading of fine aggregates (sand) or coarse aggregates (gravel or crushed stone) into trucks for delivery to batching plants. -

Loading Other Dry Additives:

Managing the transfer of other dry ingredients, such as pigments, fibers, or chemical additives used in concrete production.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...