WAM

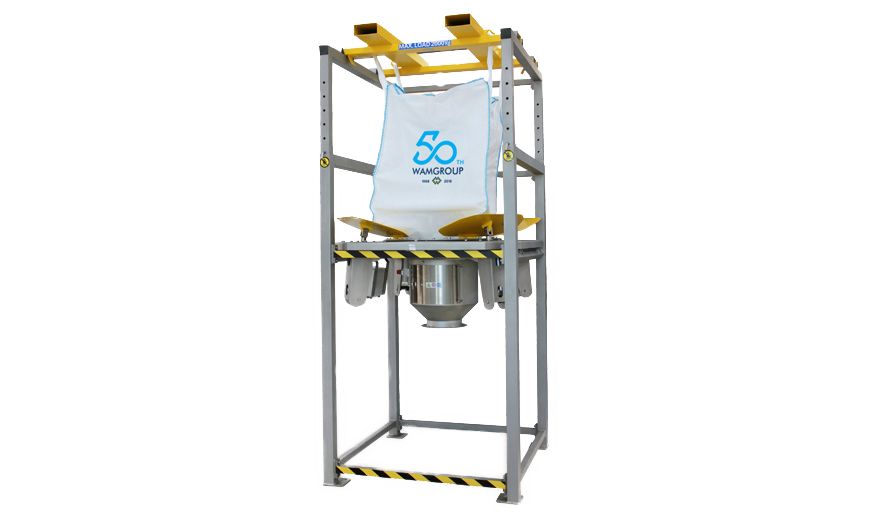

WAM SBB HFF Series FIBC (Flexible Intermediate Bulk Container) Discharging Station

WAM SBB HFF Series FIBC (Flexible Intermediate Bulk Container) Discharging Station

The WAM SBB HFF Series FIBC Discharging Station is a specialized system designed for the efficient, controlled, and dust-free emptying of bulk bags (FIBCs) containing powdery or granular materials. It plays a vital role in industries handling bulk solids, particularly in cement processing.

Key Features and Functions:

-

FIBC Support Frame: A robust frame structure designed to securely hold and support the FIBC during the discharging process.

-

Discharge Hopper: Positioned beneath the FIBC, the hopper collects material as it is emptied from the bag.

-

Dust-Free Discharging: Integrated features minimize dust emissions, ensuring a cleaner and safer working environment. This includes sealed connections and dust collection systems.

-

HFF (High Flow Function) Design: The "HFF" designation indicates a specific design optimized for high flow rates or efficient handling of materials with particular flow characteristics.

-

Vibration System (Optional): Vibration helps promote material flow from the FIBC into the hopper, ensuring complete emptying and preventing bridging or clogging.

-

Adjustable Height (Optional): Some SBB HFF models may offer adjustable height to accommodate various FIBC sizes.

-

Discharge Outlet: The hopper’s discharge outlet connects to a conveying system or collection container for further processing or transport.

-

Control Panel: An electrical control panel provides easy operation and monitoring of the discharging process.

-

WAMGROUP Branding: The image displays the WAMGROUP branding, confirming the manufacturer of the system.

-

50th Anniversary Logo: The bag in the image displays a "50" logo, marking WAMGROUP's 50th anniversary.

Applications:

-

Primarily used for emptying FIBCs containing materials like cement, lime, fly ash, and other bulk solids.

Relevance:

-

Efficient Emptying of Bulk Cement Bags: The SBB HFF discharging station efficiently empties FIBCs containing cement into downstream processes.

-

Dust Reduction: Cement dust is a significant environmental and health hazard. The SBB HFF machine’s dust control features minimize emissions, contributing to a cleaner and safer working environment.

-

Improved Material Handling: The SBB HFF streamlines the FIBC emptying process, improving ergonomics and reducing the need for manual labor.

-

Controlled Material Discharge: The hopper and discharge outlet ensure a controlled and consistent flow of cement into downstream systems.

-

High Flow Rate Capability: The HFF design allows for efficient handling of large volumes of cement.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...