WAM

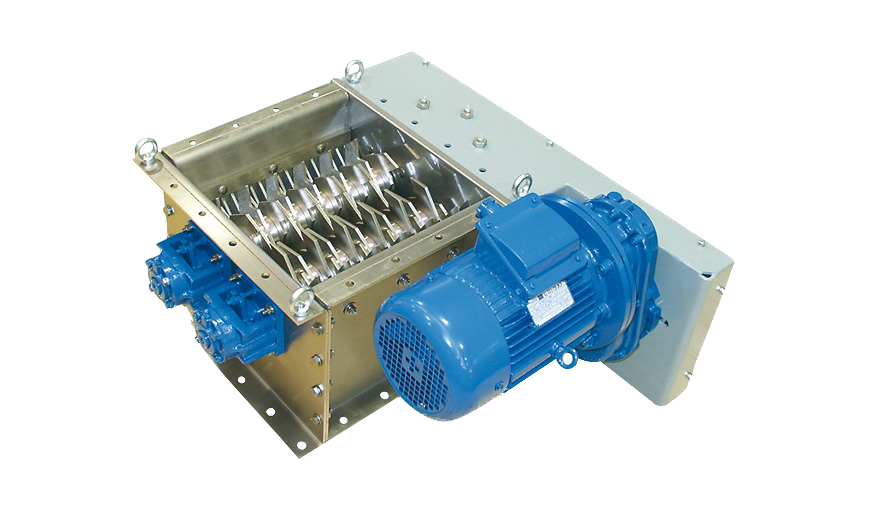

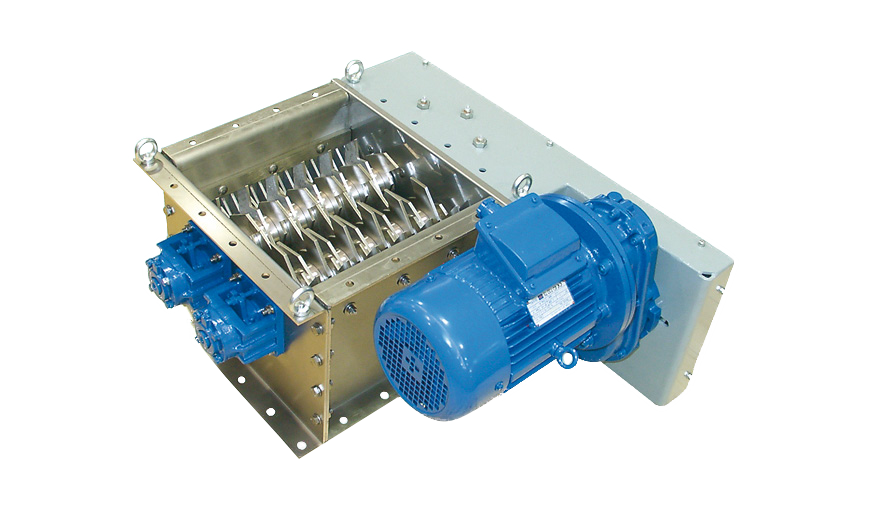

WAM DLP Double Discharge Lump Breaker

WAM DLP Double Discharge Lump Breaker

The WAM DLP Double Discharge Lump Breaker is designed to break down lumps and agglomerates in dry, granular, or powdery materials, such as cement, fly ash, aggregates, and other additives commonly used in concrete production. By preventing material blockages and ensuring consistent flow, this lump breaker plays a crucial role in optimizing material handling, thus contributing to smoother and more efficient operations in concrete plants.

Key Features and Benefits in Concrete Production:

-

Lump Breaking:

The DLP effectively breaks down lumps and agglomerates formed in materials like cement, fly ash, aggregates, and additives during storage or transportation. This ensures the proper consistency and flow of materials. -

Consistent Material Flow:

By eliminating lumps, the breaker ensures a continuous and even material flow to mixers and other processing equipment. This results in a more uniform and reliable concrete mix, which is essential for high-quality production. -

Reduced Blockages:

The DLP prevents blockages in conveying systems, silos, and other downstream equipment, significantly reducing downtime and maintenance costs associated with clogged systems. -

Improved Material Handling:

With the DLP breaker, handling and processing of materials become more efficient, leading to smoother operations and reduced material wastage in the concrete production process. -

Versatility:

Capable of handling a variety of materials used in concrete production, including cement, fly ash, aggregates, and various additives, making it a versatile solution for different material handling needs. -

Durability:

The DLP Lump Breaker is built from robust materials designed to withstand the abrasive nature of concrete ingredients and the challenging operating conditions in concrete production environments.

Applications in Concrete Production:

-

Breaking Down Lumpy Cement:

Ensures smooth and continuous flow of cement from silos to mixers, preventing disruptions in the mixing process. -

Processing Lumpy Fly Ash:

Prevents blockages in fly ash handling systems, ensuring the uninterrupted flow of this important supplementary cementitious material. -

Breaking Down Agglomerated Aggregates:

Ensures the consistent flow of fine and coarse aggregates (sand, gravel, crushed stone) to mixers, maintaining a uniform mixture. -

Processing Lumpy Additives:

Facilitates the efficient handling of dry additives like pigments, fibers, or chemical admixtures, which are often prone to lumping.

The WAM DLP Double Discharge Lump Breaker is a key piece of equipment in concrete production, ensuring that materials flow smoothly and efficiently without interruptions. By breaking down lumps, it helps maintain a high-quality concrete mix while minimizing equipment downtime and maintenance costs.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...