WAM

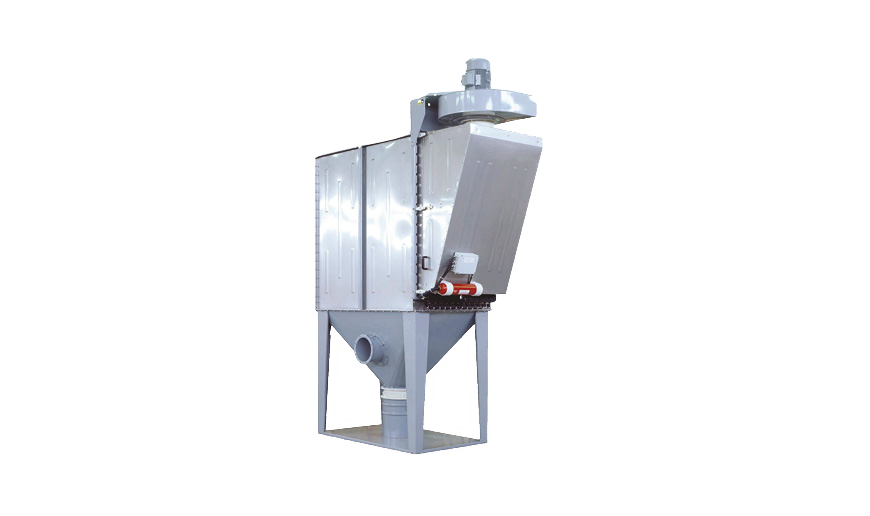

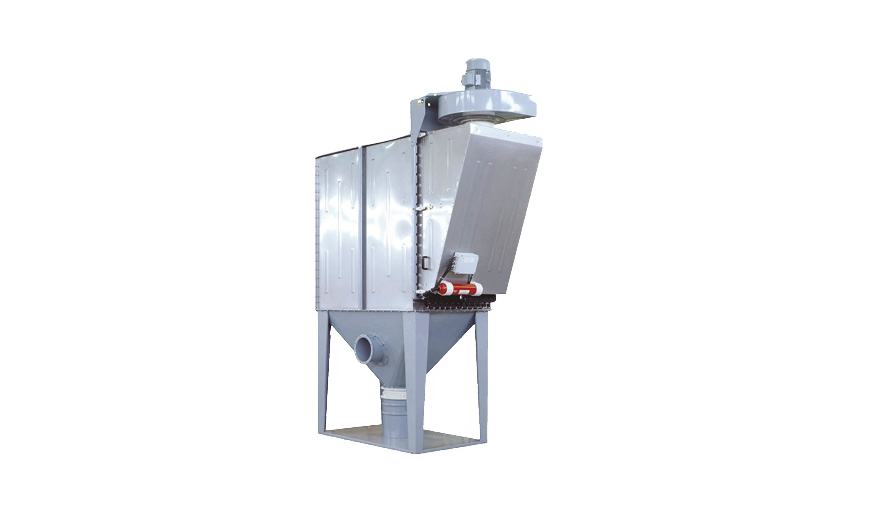

WAM Drybatch Pulse Jet Dust Collector

WAM Drybatch Pulse Jet Dust Collector

The WAM Drybatch Pulse Jet Dust Collector is specifically designed for efficient dust removal and air filtration in dry batch concrete plants. Dust is generated during various stages of concrete production, such as mixing, weighing, and transporting materials. This dust collector plays a crucial role in capturing and containing that dust, ensuring a cleaner, safer working environment and compliance with environmental regulations.

Key Features and Benefits:

-

Efficient Dust Removal:

The pulse jet cleaning system ensures that dust collected on the filter media is efficiently removed, maintaining continuous airflow and optimal dust collection performance. This helps keep the system running without interruption. -

Improved Air Quality:

By capturing fine dust particles, the dust collector improves the overall air quality inside the plant, reducing potential health risks for workers and promoting a safer working environment. -

Reduced Material Waste:

The efficient dust collection minimizes material loss during production processes (such as cement, fly ash, and other dry ingredients), which helps reduce costs and optimize the use of raw materials. -

Compliance with Environmental Regulations:

The WAM Drybatch Pulse Jet Dust Collector helps concrete plants comply with environmental standards and regulations regarding dust emissions, crucial for sustainable operations and avoiding penalties. -

Protection of Equipment:

The removal of dust prevents accumulation on sensitive equipment, which could otherwise cause wear, reduce efficiency, and lead to higher maintenance costs. It helps protect the overall longevity and reliability of plant equipment. -

Versatility:

This dust collector is adaptable to different types of dust generated during concrete production, such as cement, fly ash, and aggregate dust, ensuring effective filtration across various stages of the process. -

Durability:

Constructed from durable materials, the dust collector is built to withstand the tough operating conditions typical of concrete plants, ensuring long-term reliability and performance.

Applications:

-

Dust Collection from Batch Mixers:

The collector captures dust produced during the mixing of concrete ingredients, preventing dust from escaping into the air and maintaining a clean production area. -

Dust Collection from Weighing Hoppers:

During the weighing of cement, aggregates, and additives, dust is generated. The dust collector effectively captures this dust, keeping the weighing area clear and preventing material loss. -

Dust Collection from Silos:

Filling and emptying cement and fly ash silos often creates dust. The Drybatch Dust Collector captures this dust, ensuring that the surrounding environment remains clean and safe. -

Dust Collection from Conveying Systems:

As materials like aggregates and cement are transported through conveyors, dust can be generated. The dust collector removes this dust from the air, ensuring the system operates efficiently and safely.

The WAM Drybatch Pulse Jet Dust Collector is an essential piece of equipment in dry batch concrete plants, ensuring dust control, improving air quality, reducing material waste, and enhancing the longevity of equipment. With its versatile applications and durability, it plays a critical role in maintaining a clean, efficient, and environmentally compliant production environment.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...