WAM

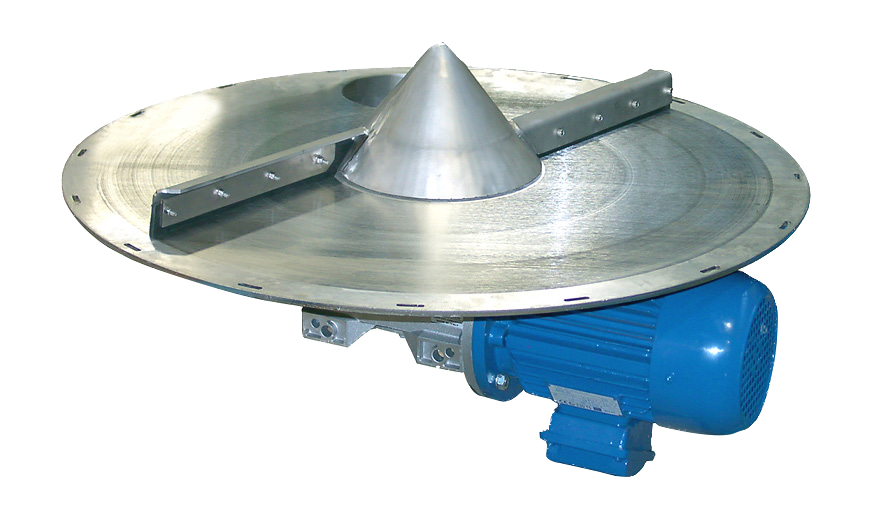

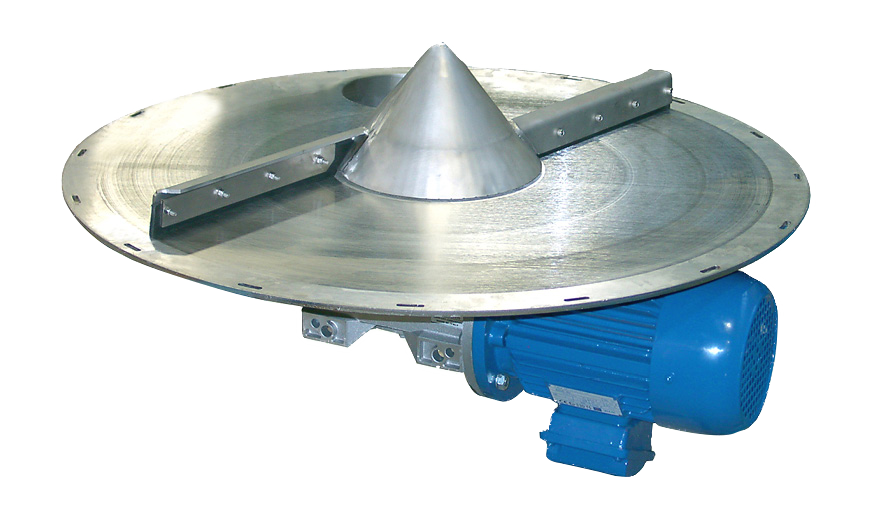

WAM Binsweep Rotary Bin Discharger

WAM Binsweep Rotary Bin Discharger

The WAM Binsweep Rotary Bin Discharger is an advanced material handling solution designed for the efficient and consistent discharge of dry, powdery, or granular materials from flat-bottom bins or silos. It is widely used in concrete production facilities to ensure the smooth flow of key ingredients like cement, fly ash, aggregates, and additives, promoting uninterrupted operations and uniform mixing.

Key Features and Benefits in Concrete Production:

-

Efficient Discharge:

The rotating blades of the Binsweep system sweep across the entire bin floor, effectively preventing material bridging and rat-holing. This guarantees continuous and smooth material flow without clogs, crucial for maintaining the efficiency of concrete production processes. -

Consistent Material Flow:

By ensuring a uniform discharge rate, the Binsweep helps achieve consistent material distribution, which is essential for producing accurate and homogeneous concrete mixes. -

Reduced Material Waste:

The Binsweep system minimizes leftover material in the bin, helping reduce waste and optimizing the overall utilization of resources in the production process. -

Improved Productivity:

The consistent material flow and reduced risk of blockages lead to fewer interruptions and less downtime, directly contributing to increased productivity and more efficient operations in concrete production. -

Versatility:

The Binsweep is highly versatile, handling various materials commonly used in concrete production, such as cement, fly ash, aggregates, and additives, adapting to the unique needs of different production environments. -

Durability:

Built with robust materials, the Binsweep is designed to withstand the harsh and demanding conditions of concrete production environments, ensuring long-lasting reliability and performance.

Applications in Concrete Production:

-

Discharging Cement from Silos:

Facilitates the smooth and continuous flow of cement to mixers, preventing clogs or delays in the batching process. -

Discharging Fly Ash from Silos:

Ensures efficient and uninterrupted fly ash handling, avoiding blockages in fly ash handling systems that could disrupt the concrete production process. -

Discharging Aggregates from Bins:

Helps maintain a uniform flow of aggregates (sand, gravel, or crushed stone) to mixers, ensuring the consistency of the concrete mixture. -

Discharging Additives from Bins:

Facilitates the discharge of dry additives, such as pigments, fibers, and chemical admixtures, ensuring precise and consistent inclusion in the concrete mix.

The WAM Binsweep Rotary Bin Discharger is an essential piece of equipment for optimizing material discharge and improving the efficiency of concrete production. By ensuring a smooth, consistent flow and reducing material waste, it helps maintain high productivity and consistent mix quality.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...