WAM

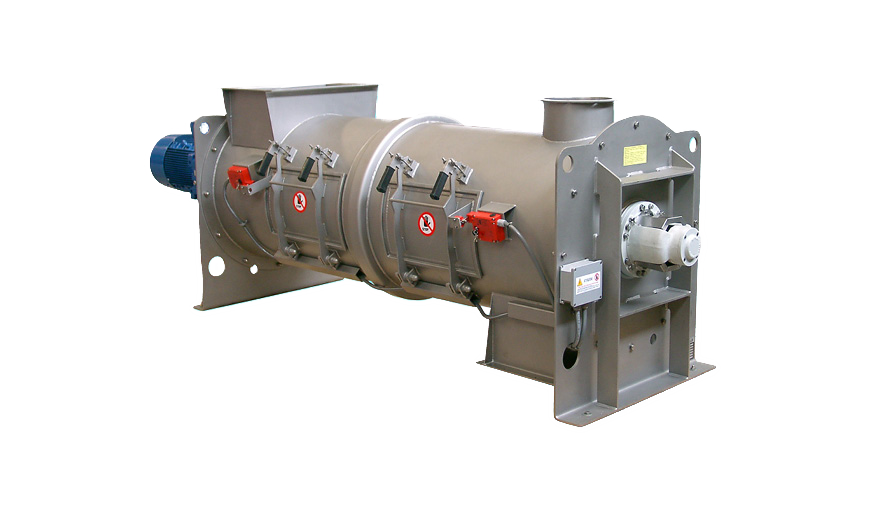

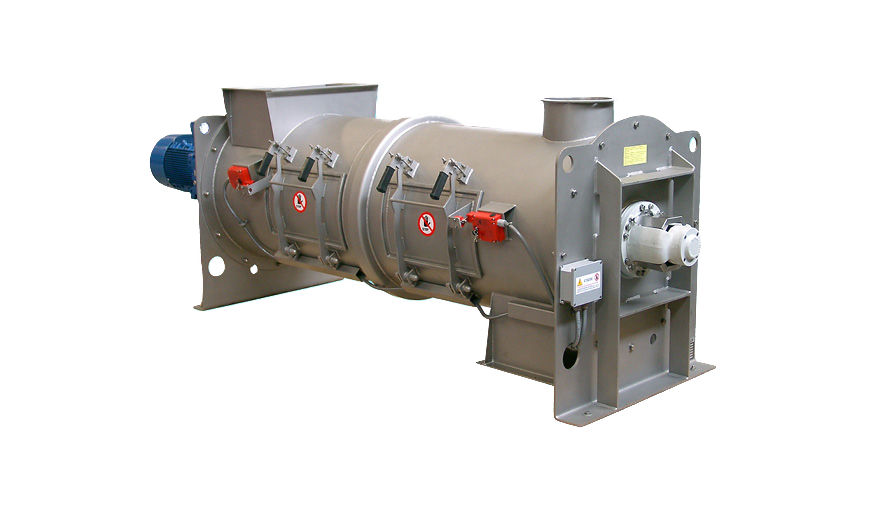

WAH Continuous Single Shaft Industrial Mixer

WAH Continuous Single Shaft Industrial Mixer

The WAH Continuous Single Shaft Industrial Mixer is a highly versatile and efficient machine designed to provide uniform mixing of dry bulk solids, powders, granules, and short fibers. It is commonly used in industries such as cement processing, chemical manufacturing, and food processing to blend and homogenize materials.

Key Features and Functions:

-

Continuous Mixing: The mixer operates continuously, ensuring a steady flow of well-mixed material, which is crucial for large-scale industrial operations.

-

Single Shaft Design: The machine features a single, horizontally mounted shaft that is equipped with rotating mixing tools. These tools, often in the form of ploughshares or blades, interact with the materials to achieve effective blending.

-

Mixing Tools: The mixing tools work dynamically within the chamber, ensuring a thorough and uniform blend of the materials. This results in a highly homogeneous product, essential in industries where consistency is key.

-

High Mixing Homogeneity: The design ensures a high level of homogeneity in the final product, ensuring consistent properties for materials like cement, chemicals, and other industrial compounds.

-

Capacity Options: The WAH mixer is available in different capacities to meet various throughput requirements, making it adaptable for both small-scale and large-scale operations.

-

Robust Construction: Built to withstand the challenges of industrial environments, the mixer is constructed from durable materials that ensure long-lasting performance.

-

Easy Maintenance: With an open design, the mixer allows for easy access to the mixing chamber and other components, simplifying maintenance and minimizing downtime.

Applications:

-

Cement Processing: The mixer is ideal for blending key cement ingredients, such as clinker, limestone, gypsum, and fly ash, to create a homogeneous mixture with the desired properties for production.

-

Chemical, Food, and Pharmaceutical Industries: Beyond cement, the WAH mixer is used for uniform mixing in other industries, including chemical, food processing, pharmaceuticals, and plastics manufacturing.

-

High-Volume Production: Suitable for high-capacity production facilities, it can handle large volumes of material, ensuring continuous output and optimal efficiency.

Specific Relevance to Cement Silo Processing:

-

Cement Blending: The WAH Continuous Single Shaft Mixer is vital for blending the components of cement, ensuring that the final mix is uniform and meets quality specifications.

-

Consistency in Product Quality: Its ability to uniformly mix materials such as clinker, limestone, and additives ensures the production of high-quality cement, which is crucial for the construction industry.

-

Large Volume Handling: The mixer’s high-capacity design makes it suitable for large-scale cement production, allowing for continuous operation and meeting the demands of modern cement plants.

Features:

-

Cylindrical Mixing Chamber: The open-ended cylindrical mixing chamber allows for continuous material flow, with inlet and outlet ports for easy integration into the production process.

-

Single Shaft with Mixing Tools: The single shaft, equipped with rotating tools, ensures consistent mixing and efficient processing.

-

Drive Motor and Gearbox: The motor and gearbox system powers the shaft, driving the mixing process efficiently and ensuring reliable operation.

The WAH Continuous Single Shaft Industrial Mixer is a highly effective solution for blending and homogenizing dry bulk materials in cement processing and a wide range of other industries. With its robust design, continuous operation, and high mixing homogeneity, it ensures a consistent product quality and optimal efficiency in industrial settings.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...