Sermac

Sermac Hopper Mixer Parts and Accessories

Sermac Hopper Mixer Parts and Accessories

Hopper mixer assemblies are essential components in Sermac concrete pumps, ensuring homogeneity and proper flow of the concrete mix from the hopper into the pumping cylinders. This product group includes mechanical parts associated with the mixer mechanism and supporting components that ensure efficient operation and extended service life. Additionally, this category includes lubrication accessories specifically designed for Sermac equipment, supporting long-term durability of wear-prone components.

Key Features:

Mixer Mechanical Components (Sermac-Specific):

-

High-Durability Build: Engineered from wear-resistant steel and alloys suitable for high-load and abrasive concrete environments.

-

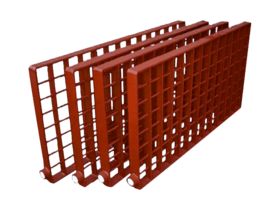

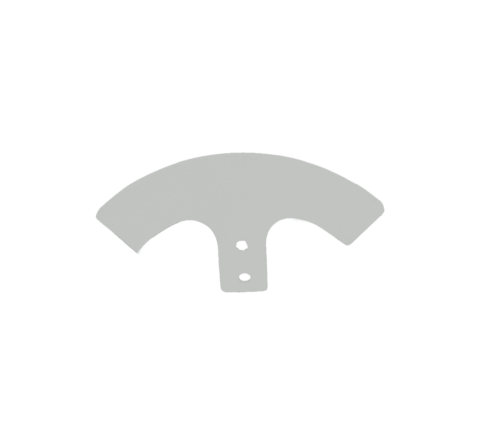

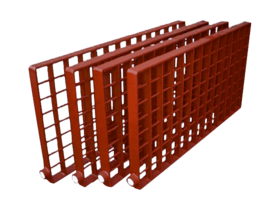

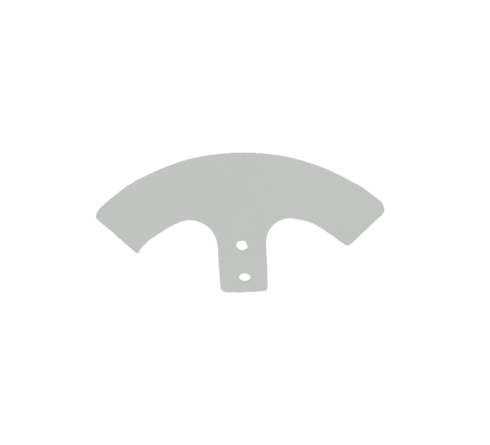

Agitation Blades and Arms: Designed for optimal mixing efficiency and reduced concrete separation.

-

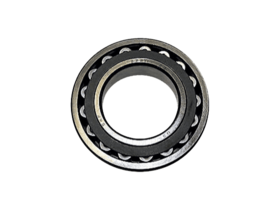

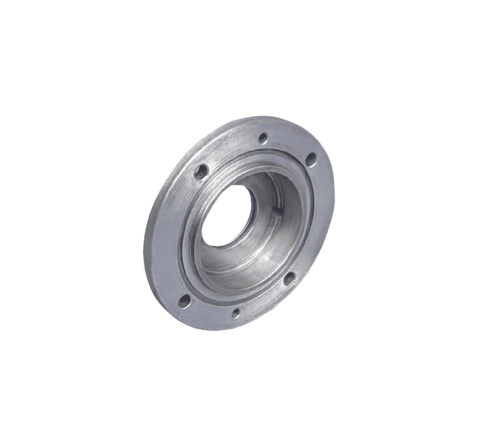

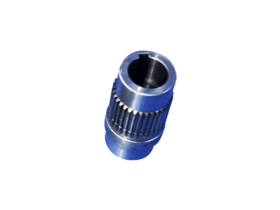

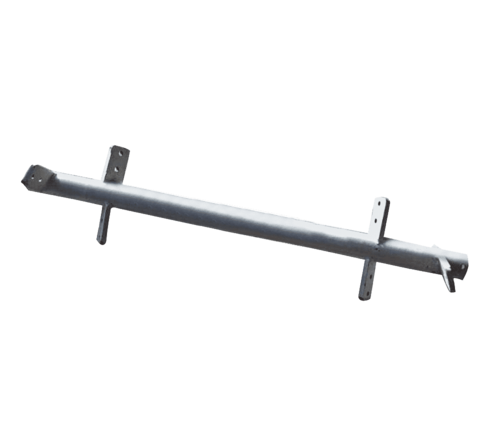

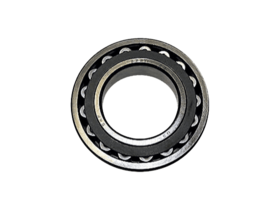

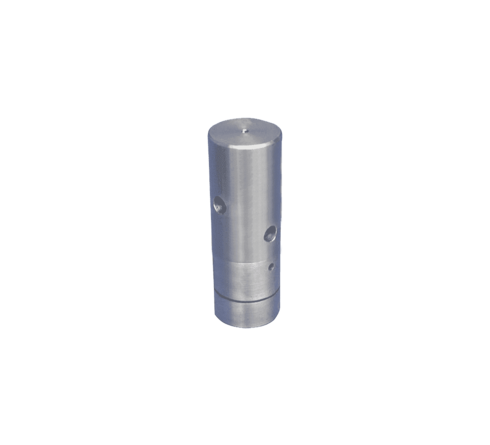

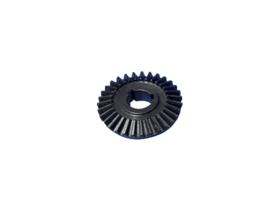

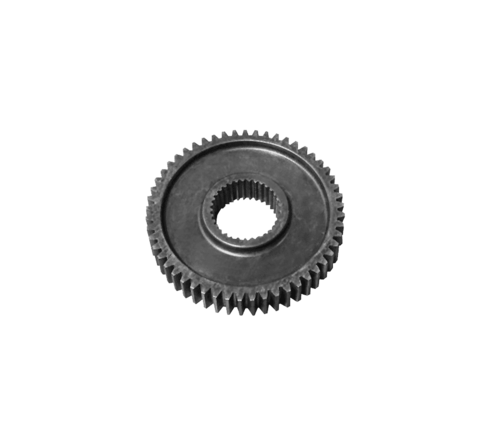

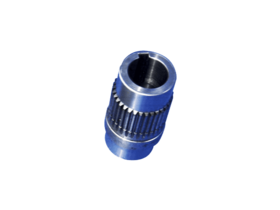

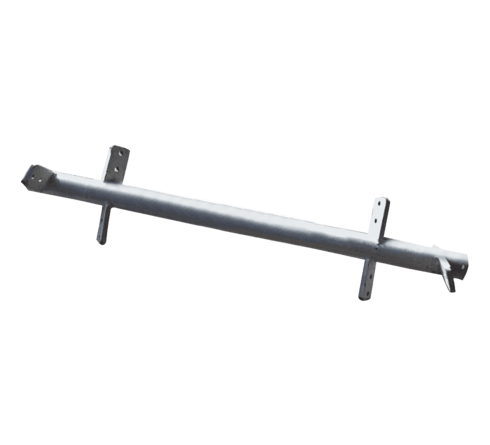

Drive Systems: Includes shafts, couplings, and bearings engineered for smooth torque transmission and long operational cycles.

-

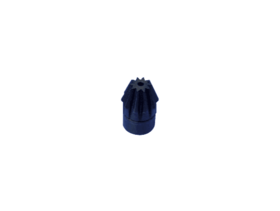

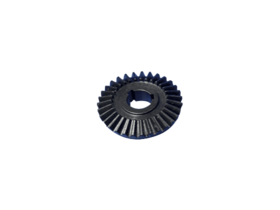

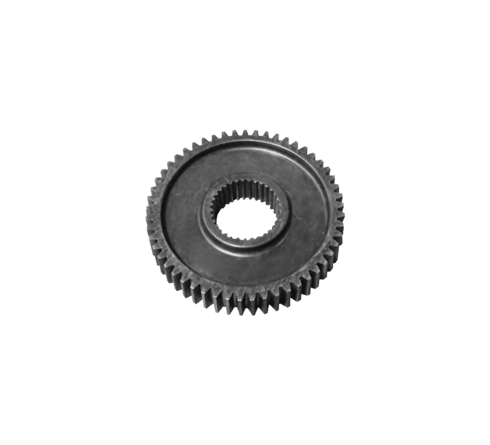

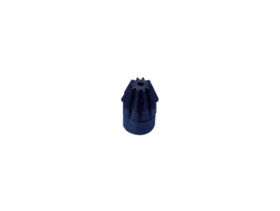

Power Transmission Components: Gears, bushings, and sprockets tailored for Sermac mixer assemblies, providing precise alignment and stable motion.

-

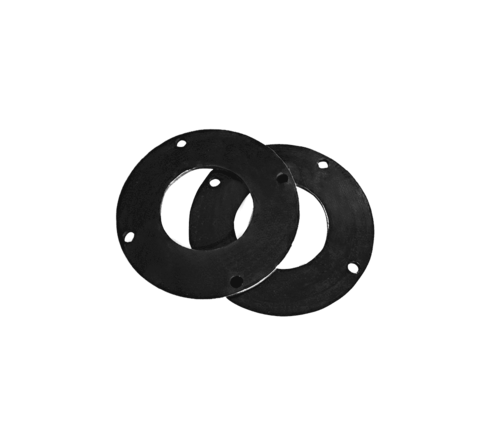

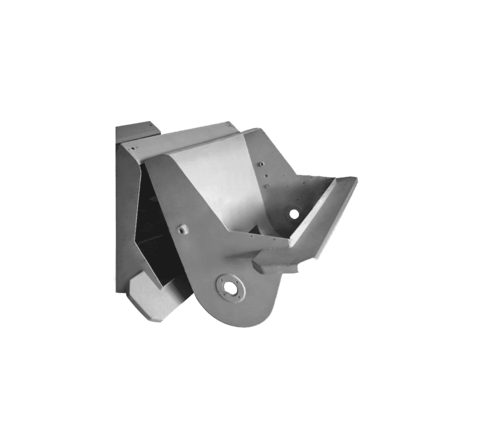

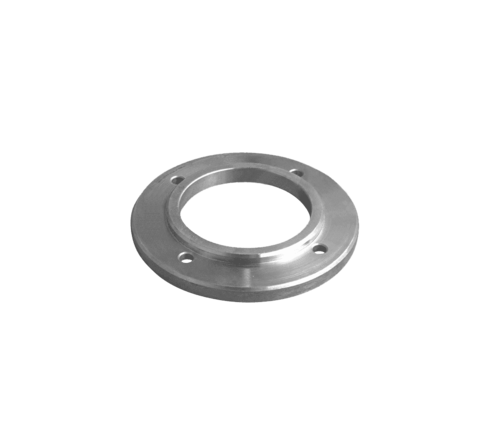

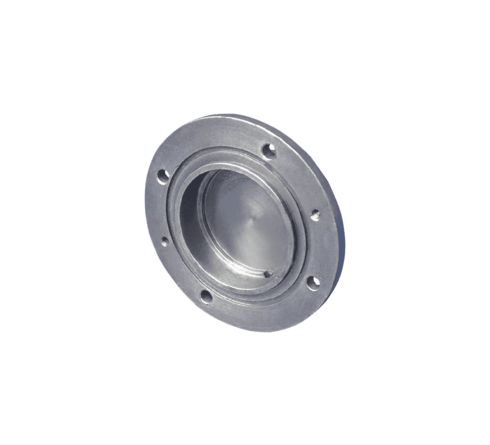

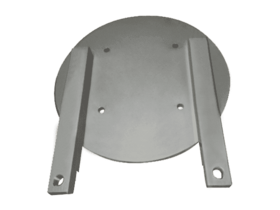

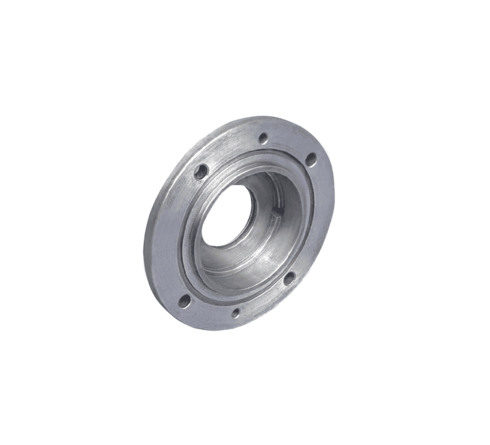

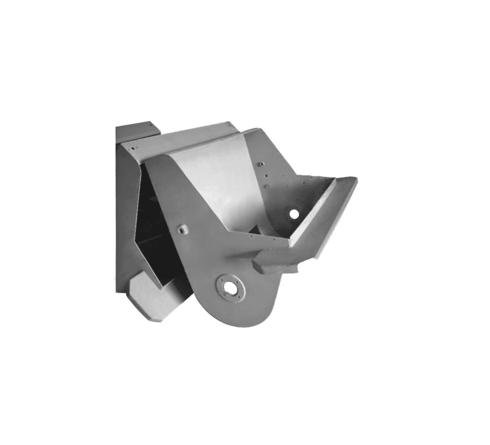

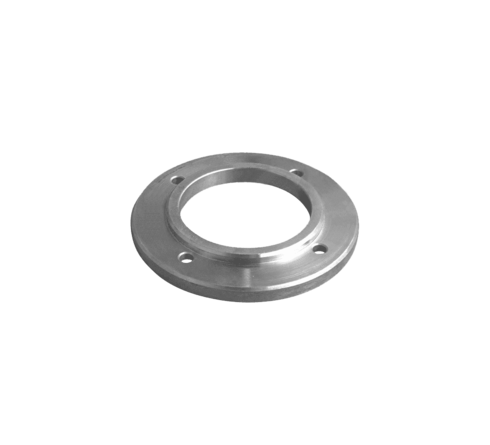

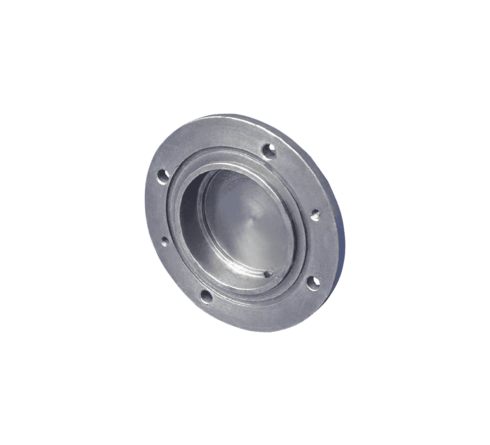

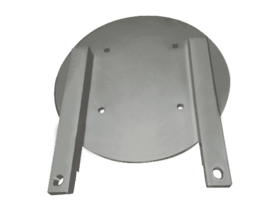

Mounting Hardware and Structural Supports: Plates, brackets, and flanges compatible with Sermac hopper configurations for secure installation.

-

Seals and Housings: Sealing components and bearing housings designed to protect internal systems from concrete ingress and dust exposure.

Lubrication Accessories (Sermac-Compatible):

-

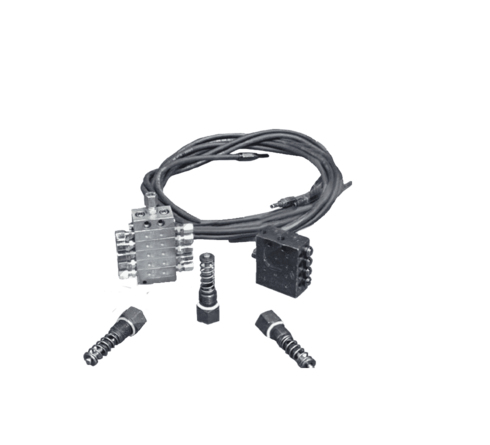

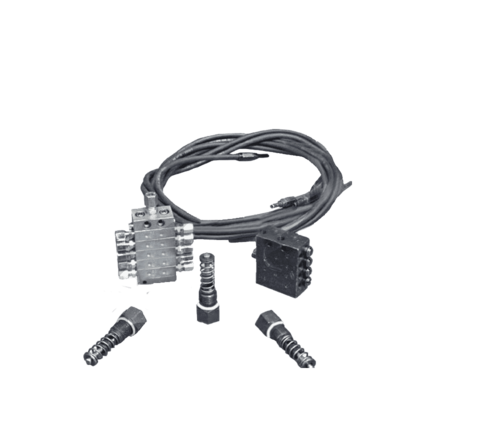

Automatic Lubrication Units: Components compatible with centralized lubrication systems to maintain consistent greasing of mixer bearings and drive components.

-

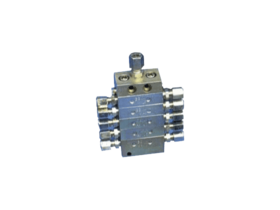

Distribution Blocks and Fittings: Multi-port grease distributors and connectors engineered for use in multi-line lubrication configurations.

-

Reservoirs and Pumps: High-capacity grease/oil reservoirs and dosing pumps built to support extended maintenance cycles.

-

Mounting and Support Elements: Vibration isolators and collars to maintain system integrity under operational stress.

Applications:

-

Prevents concrete segregation in hopper zone.

-

Ensures uninterrupted flow into pumping cylinders.

-

Reduces wear and mechanical failure of moving components.

-

Enhances overall durability of Sermac pumping equipment.

-

Supports extended equipment lifespan through automated lubrication.

Recommended Use:

To maintain performance and reliability in your Sermac concrete pump hopper system:

-

Use only OEM-compatible components.

-

Match parts to the exact Sermac model and series in operation.

-

Ensure proper lubrication coverage via approved centralized systems.

-

Replace wear parts at regular intervals as per Sermac maintenance guidelines.

Product Selection Guidance:

When ordering components from this category:

-

Provide your Sermac model number and hopper configuration.

-

Specify part dimensions or any stamped identification numbers.

-

Confirm compatibility with existing gearbox, drive shaft, or lubrication system.

-

For lubrication parts, reference system capacity and type (grease/oil).

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...