Schwing

Schwing Rock Valves and Accessories

Schwing Rock Valves and Accessories

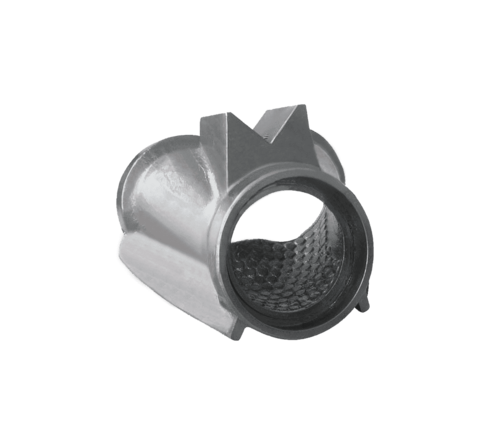

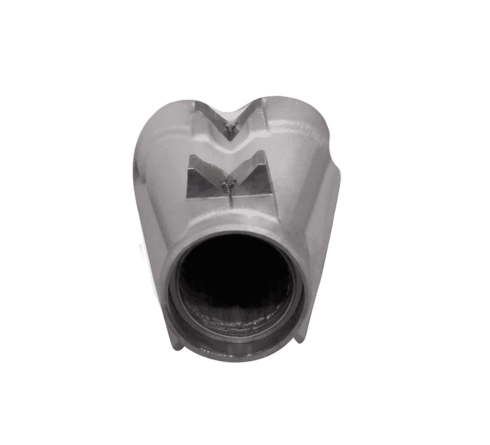

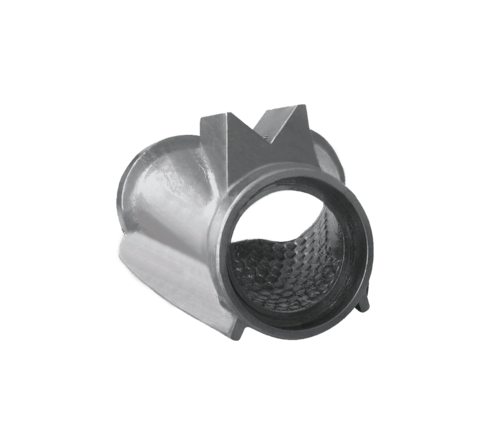

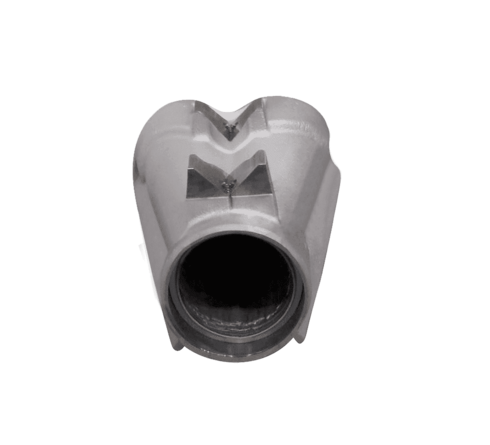

Rock valves, also known as S-valves or swing tube valves, are a core component in Schwing concrete pumps. These valves enable continuous concrete flow by alternately connecting each delivery cylinder to the outlet and hopper during the suction and pressure strokes. Accessories in this category include wear components, seals, shafts, and housings required for the reliable operation and maintenance of the valve assembly.

Key Features

-

Oscillating Valve Mechanism: Alternates the concrete flow between the pump cylinders and delivery line using a durable swing action

-

High Wear Resistance: Built from abrasion-resistant alloys and hardened steels to handle demanding concrete flow conditions

-

Sealing Efficiency: Utilizes precision-fit O-rings, backup rings, and sealing surfaces to minimize leakage and maintain internal pressure

-

Heavy-Duty Construction: Engineered to withstand repeated hydraulic actuation and high-pressure cycles

-

Serviceable Design: Components are designed for quick inspection, removal, and replacement to minimize downtime

Common Components

| Component | Description |

|---|---|

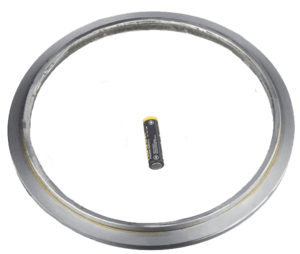

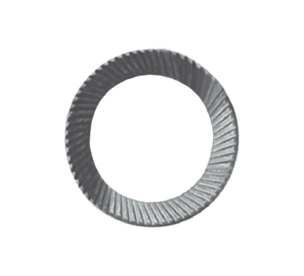

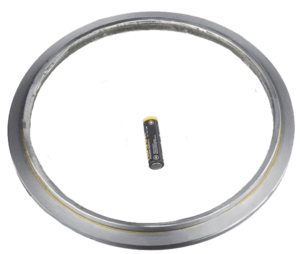

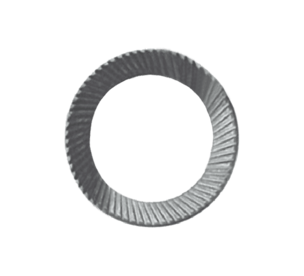

| Wear Ring (DN 210, etc.) | Fits into the valve chamber to protect against abrasion and maintain a tight seal |

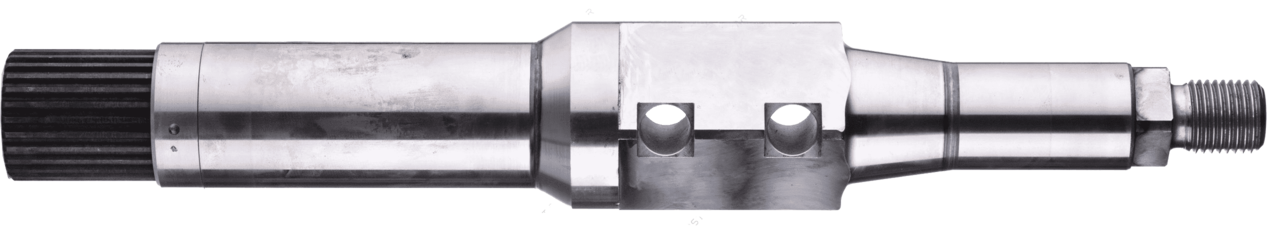

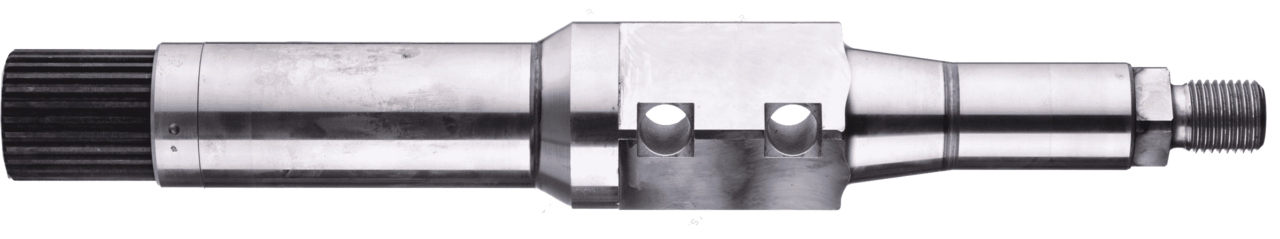

| Pivot Shaft | Central axle for valve oscillation, typically precision-machined with stepped diameters |

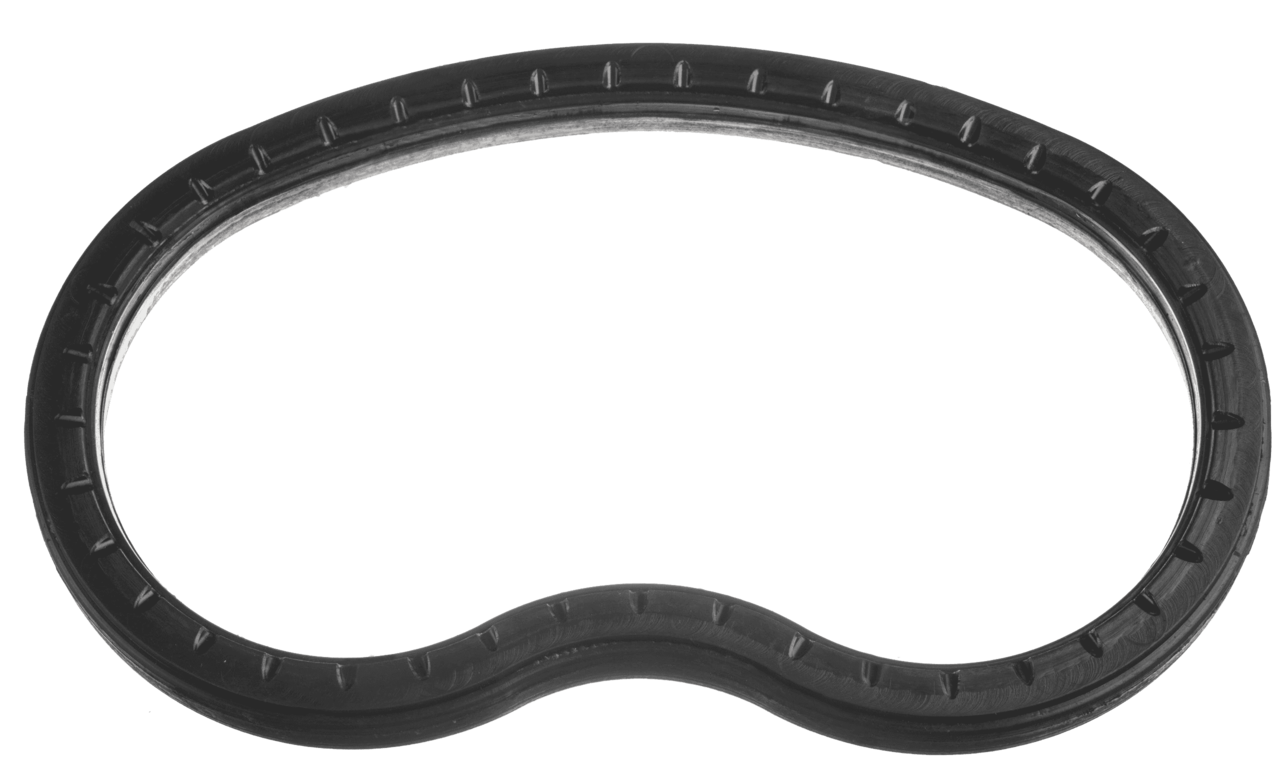

| O-Rings & Backup Rings | Seal interfaces and prevent hydraulic fluid or concrete leakage |

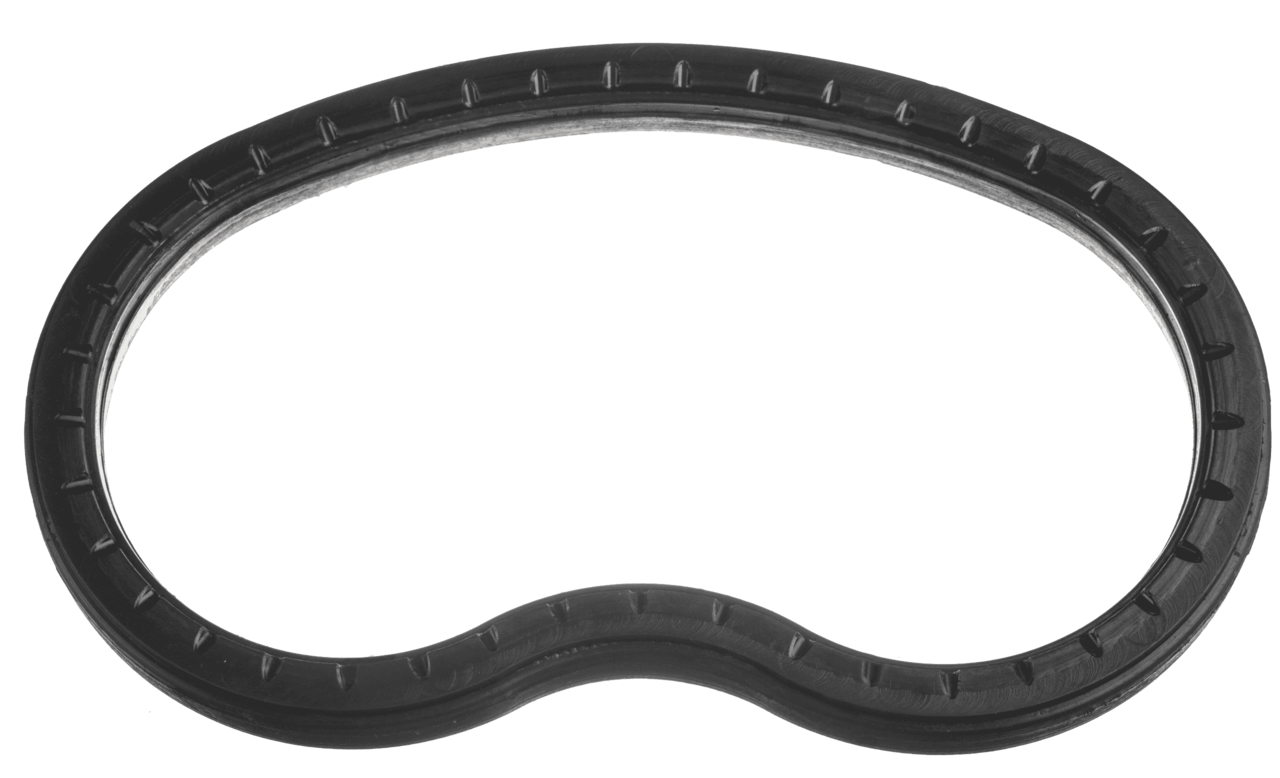

| Sealing Inserts & Gaskets | Custom-shaped elements for critical sealing points within the valve system |

| Valve Housing Segments | Form the cavity for the swing tube and support its motion |

| Wear Sleeves & Liners | Inserted into high-wear areas to extend valve body life |

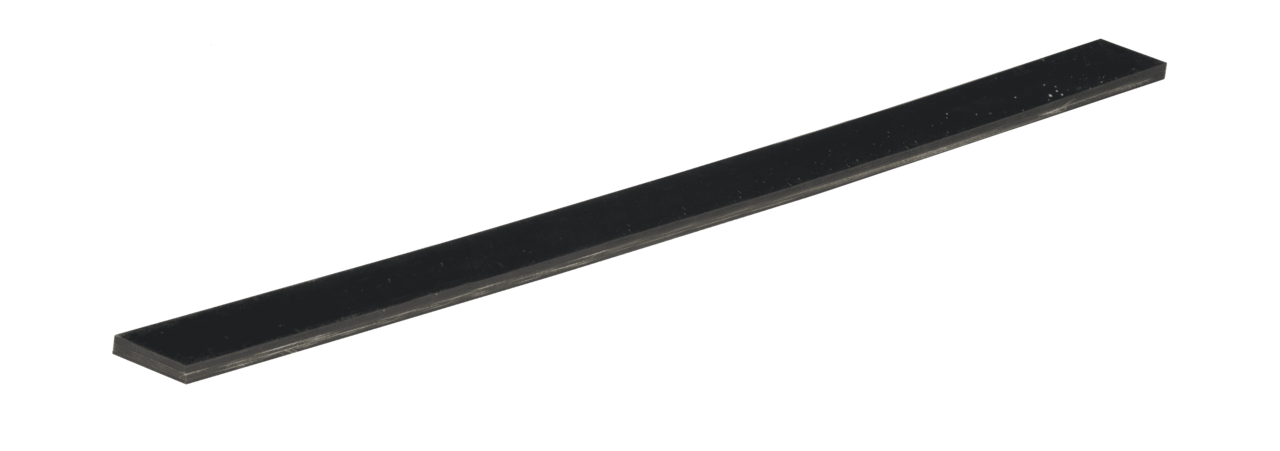

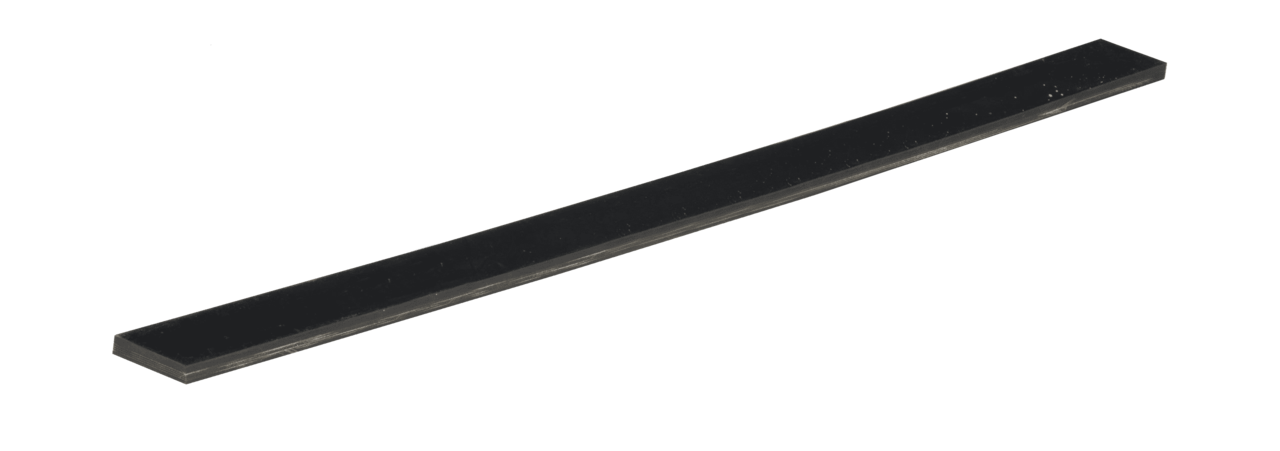

| Scraper Blades & Guides | Remove concrete residue and maintain alignment of moving parts |

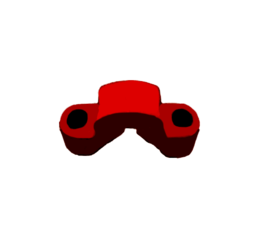

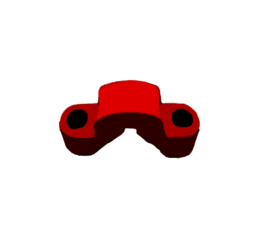

| Hydraulic Connection Plates | Interface between hydraulic cylinders and the swing arm |

| Retaining Rings & Locks | Secure rotating or mounted components in place during operation |

Applications

-

Manages the switching of concrete flow between cylinders and the outlet line

-

Located below the hopper in the pump’s valve chamber

-

Used in truck-mounted concrete pumps, stationary pumps, and trailer-mounted units

-

Ensures uninterrupted concrete delivery in both high- and low-output scenarios

Selection & Maintenance Tips

-

Always match components to the pump model and series

-

Use precise part numbers and measurements to ensure compatibility

-

Inspect wear parts regularly for signs of abrasion, cracking, or seal fatigue

-

Replace seals and wear rings proactively to avoid unexpected downtime

-

Lubricate pivot points and maintain hydraulic connections to support smooth operation

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...