Schwing

Schwing Remote Control Systems and Valves

Schwing Remote Control Systems and Valves

This product group includes the remote control systems and actuated valve assemblies used to control and manage the operation of Schwing concrete pumps—especially boom placement, pump performance, and auxiliary functions. These components are essential for enabling safe, efficient, and precise pump operation from a distance.

Remote Control Systems

Functionality:

Enables wireless or wired control over key machine functions including:

-

Boom movement (slewing, lifting, telescoping)

-

Pump start/stop

-

Output rate control

-

Water pump activation

-

Emergency stop

(Some models may support outrigger operation)

Key Features:

-

Wireless Connectivity: Uses RF technology for safe, long-distance control

-

Proportional Joystick Control: Allows fine adjustment of hydraulic functions

-

Ergonomic Design: Lightweight with padded straps or harnesses for comfort

-

Durability: IP-rated enclosures for water, dust, and shock resistance

-

Safety Systems: Emergency stop, status LEDs, secure pairing protocols

-

Battery Options: Rechargeable lithium-ion or replaceable battery packs

-

Wired Backup: Some systems offer failover wired control (via coiled cable)

Common System Examples:

-

HBC Radiomatic handheld transmitters (with or without display)

-

Scanreco or Hetronic systems on select international models

-

Wired pendants for ground-level or emergency use

Actuated Valve Assemblies

Functionality:

These valves interpret electrical or pneumatic control signals (often from a remote control receiver or pump PLC) to direct fluid flow within the hydraulic or pneumatic circuits of the pump.

Types of Valves:

-

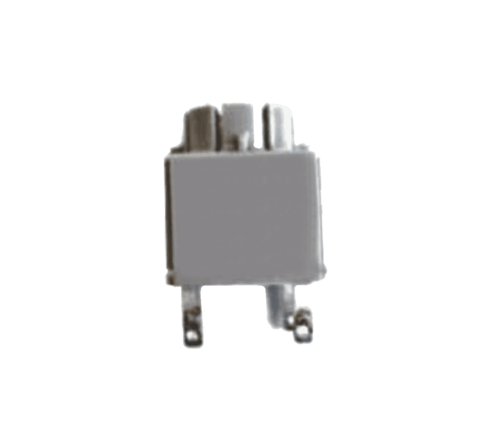

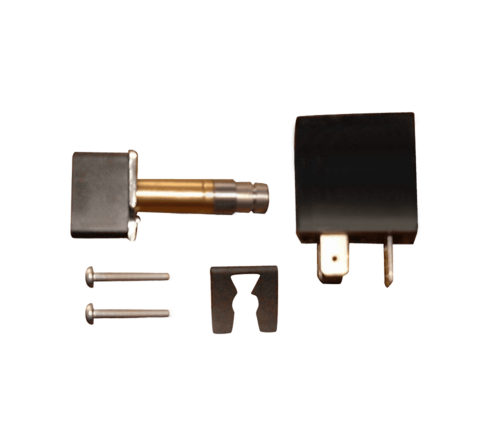

Solenoid Valves:

-

Electrically controlled

-

Used for directional flow in hydraulic circuits

-

Compact and responsive

-

-

Pneumatic Valves:

-

Air-powered, used in auxiliary systems

-

Reliable in harsh environments

-

-

Proportional Valves:

-

Allow variable flow or pressure control

-

Used for smooth boom or pump output adjustments

-

Controlled via analog/digital input from the remote system

-

Key Features:

-

High-pressure capability (rated for concrete pump hydraulic demands)

-

Precision-machined internal ports

-

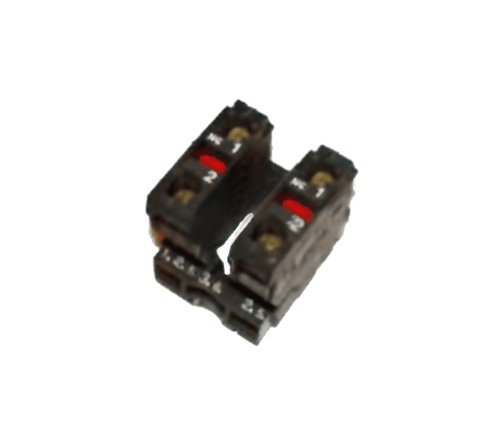

Modular valve blocks or manifolds for space-saving installations

-

Available in various voltage ratings (12V, 24V, etc.)

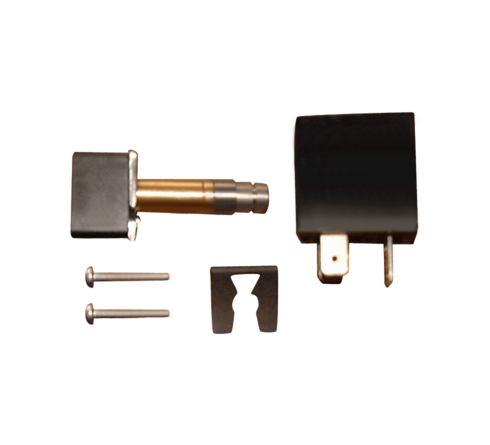

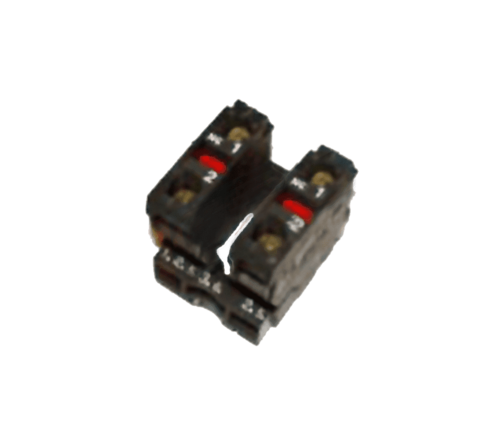

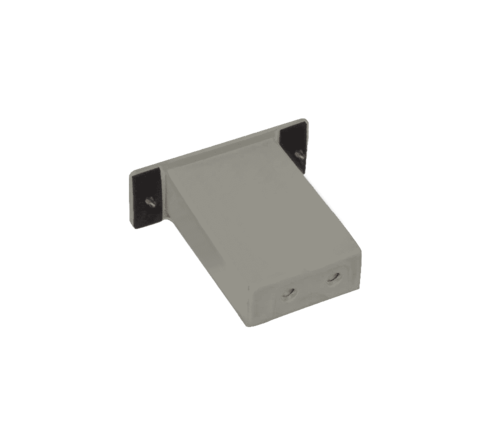

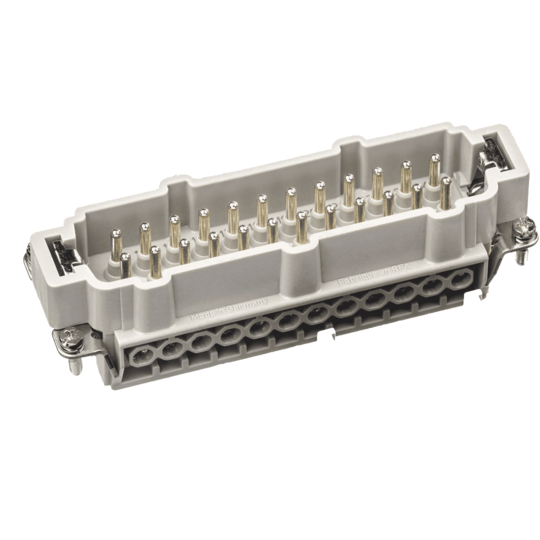

Component Highlights (Visual Identification Guide)

| Component | Likely Function |

|---|---|

| Coiled cable with plug + handheld unit | Wired remote or emergency pendant |

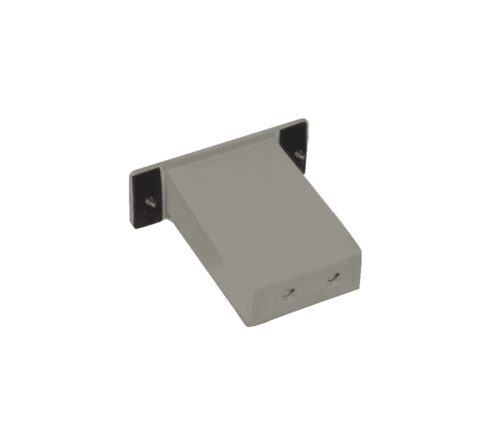

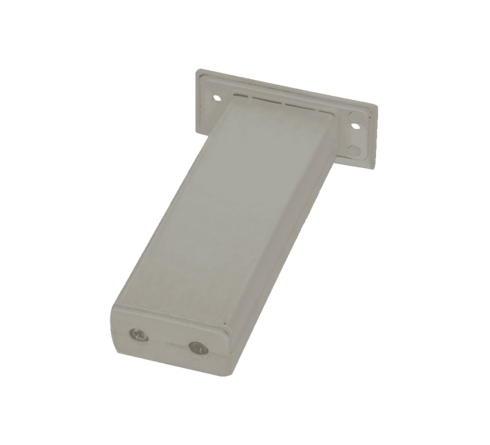

| Grey/silver rectangular boxes with ports | Control receiver modules or interface units |

| Joysticks with rubber boots | Proportional control levers (boom/valve control) |

| Black harness/strap | Carry strap for remote transmitter |

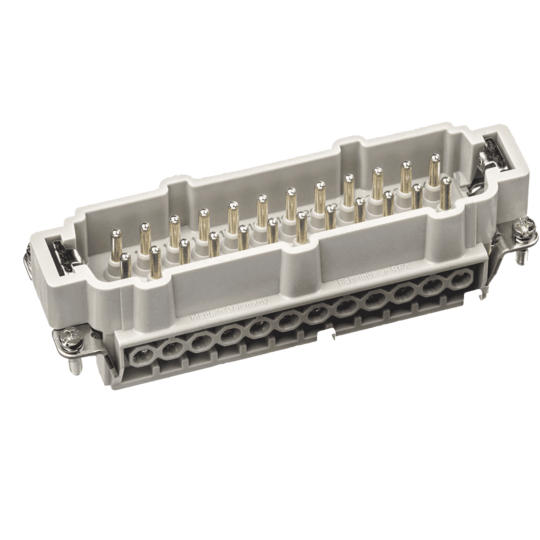

| Multi-pin connectors | Electrical connections between control system and valves |

| Pushbuttons, toggles, rotary switches | Onboard or remote user interface elements |

| Cylindrical orange/grey unit | Proximity sensor or feedback device |

| Compact black control box | Relay or interface module for electrical systems |

| Valve block with solenoids and ports | Multi-valve manifold for boom/pump control |

Installation & Identification Tips:

To ensure compatibility and proper operation:

-

Verify Schwing pump model and serial number

-

Check the existing remote system’s transmitter/receiver brand and model

-

Inspect valve blocks for engraved/stamped part numbers or tags

-

Note voltage and connector types for electrical components

-

Refer to the Schwing parts manual or wiring diagrams

-

Capture photos of control panels, joysticks, or valve assemblies for reference

Why Genuine or Compatible Remote & Valve Systems Matter

Using correct, system-compatible remote and valve components:

-

Increases operator safety and control accuracy

-

Ensures long-term reliability under jobsite stress

-

Avoids costly misfires, boom drift, or pumping delays

-

Maintains Schwing warranty and serviceability

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...