Schwing

Schwing Flat Gate Valves

Schwing Flat Gate Valves

Flat Gate Valves – Schwing

Product Category: Material Delivery System Components

Brand: Schwing

Application: Truck-Mounted Concrete Pumps

Description:

Flat gate valves play a vital role in Schwing concrete pumps, particularly within the material delivery system. These valves control the flow of concrete slurry through the delivery line, ensuring proper material flow and system isolation. The flat gate, or blade, slides across the pipeline to either open or close the passage. Due to the abrasive nature of concrete, these valves are designed to endure harsh conditions, providing robust and reliable performance.

Key Features:

-

Straight-Through Flow Path

When fully open, the flat gate valve offers an unobstructed flow, reducing pressure drop and minimizing wear on the pump and piping system. -

Abrasion-Resistant Construction

Made from high-strength, wear-resistant materials (e.g., hardened steel alloys) to withstand the grinding and erosive nature of the concrete slurry. Some internal parts may also feature specialized coatings to increase longevity. -

Tight Shut-Off

Designed to provide a secure, leak-proof seal when closed, effectively preventing concrete flow. This is critical for maintenance, section isolation, and preventing unwanted material leakage during pump operation. -

Actuation Options

Can be operated hydraulically for remote control and faster operation, or manually via a lever or handwheel for more localized control. Hydraulic actuation is commonly used in larger concrete pumps for efficient operation. -

Durable Construction

Built to handle high pressures and mechanical stress, ensuring the valve performs reliably throughout the pumping process. -

Maintenance-Friendly

Features that enable easy inspection, cleaning, and replacement of wear components such as the gate, seals, and actuator components.

Potential Applications in Schwing Concrete Pumps:

-

Main Concrete Delivery Line Control

Used to regulate the flow of concrete, allowing for a controlled, steady supply to the pump. -

Pipeline Isolation

Used to isolate specific sections of the pipeline for cleaning or maintenance without disrupting the rest of the system. -

Flow Direction Control

Directs the flow of concrete to different outlets or areas as needed, depending on the pump’s configuration. -

Backflow Prevention

Prevents reverse flow of concrete, which could otherwise lead to clogging or contamination of the pump’s delivery system.

Series/Types (General Overview Based on Visual Cues):

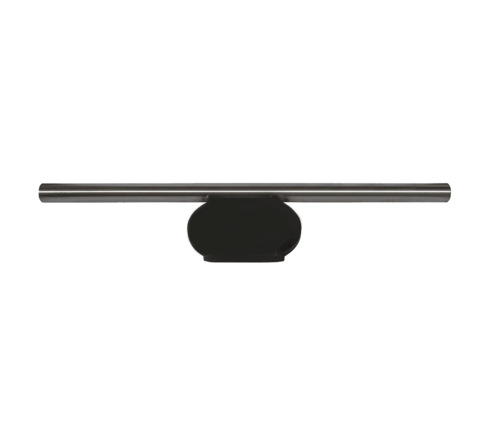

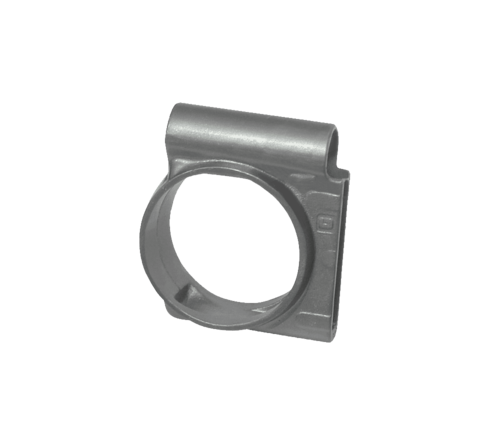

The components shown in the image likely represent parts of a Schwing flat gate valve assembly. While the image does not provide an explicit full view of the valve, based on typical designs, the main parts are:

-

Valve Body: A strong housing with inlet and outlet ports that form the core of the valve assembly. It provides a cavity for the gate and seals.

-

Gate (Blade): A flat, movable piece that slides to block or open the flow path. It is generally the main wear component, which may need to be replaced over time.

-

Seats: Replaceable sealing surfaces where the gate closes to ensure a tight shut-off. Proper sealing is essential for preventing leaks and maintaining system pressure.

-

Actuator (Hydraulic or Manual): A mechanism for moving the gate. Hydraulic actuators provide faster, more powerful operation, while manual actuators (levers or handwheels) offer more control for smaller pumps.

-

Seals and Packing: Prevent fluid leakage around the stem and connections of the gate, helping maintain system integrity.

-

Bonnet (or Top Works): The upper part of the valve housing, often designed to house the gate and its stem.

Identification & Ordering Tips:

To ensure you receive the correct flat gate valve for your Schwing concrete pump:

-

Identify the Model and Serial Number: This is crucial for selecting the right part for your specific equipment.

-

Consult the Schwing Parts Manual or authorized supplier to ensure compatibility.

-

Look for the Part Number: If available, the part number printed on the valve or its components will simplify identification.

-

Specify the Valve’s Function and Location: Understanding whether the valve is intended for controlling flow, isolating sections, or preventing backflow helps ensure the right type is selected.

-

Provide Dimensions and Markings: If possible, provide exact dimensions or identifying marks to assist in proper selection.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...