Schwing

Schwing Flanges and Sealings

Schwing Flanges and Sealings

Flanges & Sealings

Product Category: Hydraulic & Fluid System Components

Brand: Schwing

Application: Truck-Mounted Concrete Pumps

Description:

This product category includes a variety of flanges and sealing elements designed specifically for Schwing concrete pumps. These components are vital for maintaining leak-free, high-pressure connections across hydraulic, water, and material delivery systems. Flanges provide robust mechanical connections, while sealings (such as O-rings and wear rings) ensure fluid containment and system integrity under extreme operating conditions.

Key Features:

Flanges

-

Heavy-Duty Construction

Engineered from high-grade steel or alloy materials to handle pressure fluctuations, vibration, and mechanical stress typical in concrete pump operations. -

Precision Machined

Manufactured to tight tolerances to guarantee alignment and leak-free joints. -

System-Specific Designs

Available in threaded, welded, or clamped styles depending on the type of line (hydraulic, water, or concrete). -

Direct Fitment

Designed to meet Schwing’s specifications for easy integration into existing equipment.

Sealings

-

Premium Elastomeric Materials

Made from NBR, Viton®, PTFE, polyurethane, and other advanced materials for chemical compatibility and wear resistance. -

Leak Prevention Technology

Built to maintain system pressure and prevent contamination by blocking fluid and slurry leaks in both static and dynamic applications. -

Application-Specific Types

Includes standard O-rings, guide rings, lip seals, shaft seals, and wear rings for hydraulic cylinders and pump systems.

Common Types in Schwing Equipment:

| Component Type | Description / Use Case |

|---|---|

| O-Rings | Standard round seals for static and dynamic connections in hydraulic and water systems. |

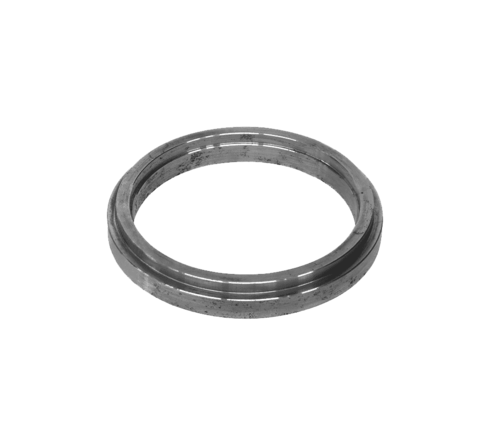

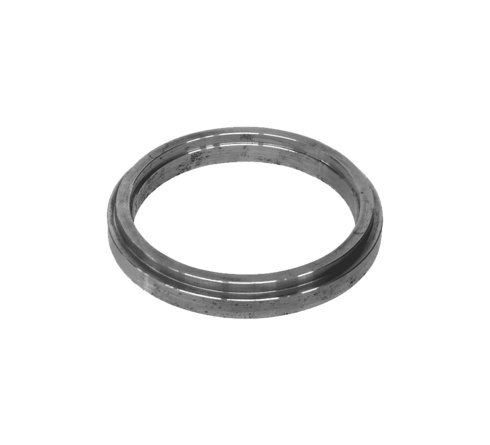

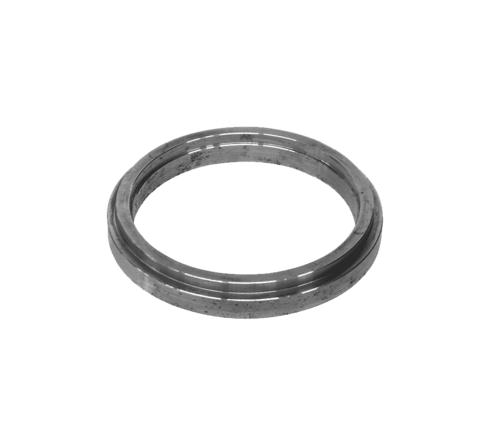

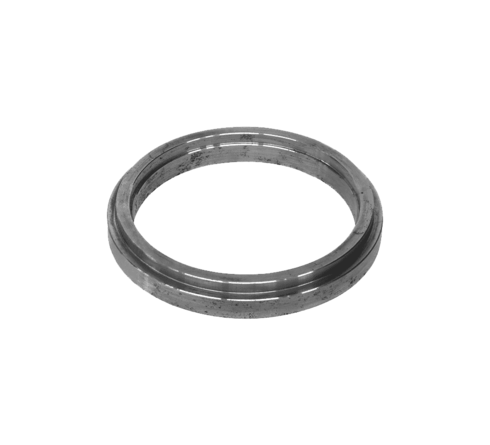

| Wear Rings / Guide Rings | Polymer-based rings guiding pistons and rods in cylinders to prevent metal-on-metal contact. |

| Threaded Flanges | Connect hydraulic lines and fittings in serviceable locations. |

| Welded Flanges | Permanent, pressure-tight pipe and pump line joints. |

| Clamp Flanges | Quick-connection flanges for systems requiring frequent disassembly or cleaning. |

| Retaining Rings | Hold seals or bearings in place inside housings or cylinders. |

Typical Applications in a Schwing Concrete Pump:

-

Hydraulic Systems:

Flange connections and sealing points on pumps, valves, cylinders, and control blocks. -

Water Systems:

Water cleaning and cooling line connections with sealing elements to prevent pressure loss. -

Material Delivery Lines:

Selected flanges used at the connection points in delivery systems (e.g., clamps or wear sleeves). -

Boom and Cylinder Assemblies:

Wear rings and seals prevent leakage and maintain piston rod guidance within hydraulic cylinders.

Identification & Ordering Tips:

To ensure correct selection:

-

Confirm the pump model and serial number.

-

Consult the Schwing parts manual or OEM supplier.

-

Reference the part number on the existing component.

-

Specify system location (hydraulic, water, or concrete delivery line).

-

Provide exact dimensions (ID/OD/thickness) if markings are missing.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...