Schwing

Schwing Concrete Pistons and Additionals

Schwing Concrete Pistons and Additionals

Product Category: Concrete Pistons and Additionals

Brand Compatibility: Schwing (OEM or compatible replacement parts)

Product Description:

Concrete pistons are critical components in the main pumping cylinders of Schwing concrete pumps, driving the movement of concrete through the pump. Each piston performs the suction and pressure strokes required to draw concrete in from the hopper and push it through the delivery line. Engineered for durability and sealing performance, these pistons are essential for maintaining pump efficiency and minimizing downtime.

“Additionals” refers to related parts that interface with or support the piston assembly, such as piston rods, wear rings, seals, and fastening hardware.

Key Features:

-

Wear-Resistant Construction:

Built with a robust steel core and an abrasion-resistant rubber or polyurethane outer layer, designed to withstand the harsh wear of concrete pumping. -

Precision Sealing:

Engineered to create a tight dynamic seal against the cylinder wall, minimizing slippage and pressure loss. -

High Compatibility:

Designed specifically for Schwing pump models, ensuring exact fit and smooth integration with the hydraulic and mechanical systems. -

Variable Configurations:

Available in multiple sizes, designs, and materials to match the requirements of different concrete types, pressures, and pump models. -

Long Service Life:

Materials and design focus on resisting damage from slurry abrasion, pressure cycling, and misalignment over extended periods.

Applications Within Schwing Concrete Pumps:

-

Suction Stroke: Draws concrete from the hopper into the pumping cylinder.

-

Pressure Stroke: Forces concrete from the cylinder into the delivery pipeline.

-

Sealing and Efficiency: Maintains internal pressure and prevents leakage of concrete material during operation.

-

Structural Support: Connects securely to the piston rod for precise actuation via the hydraulic system.

Component Types (Visual Identification):

-

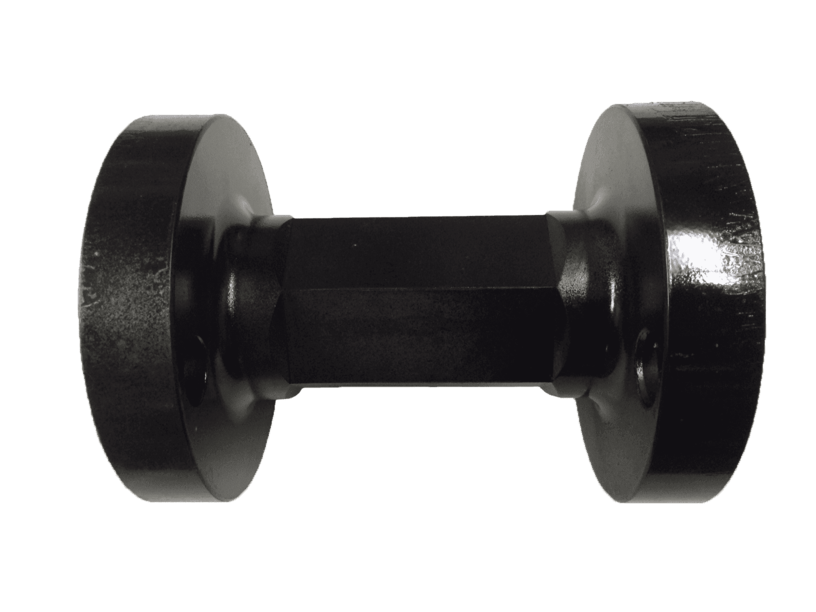

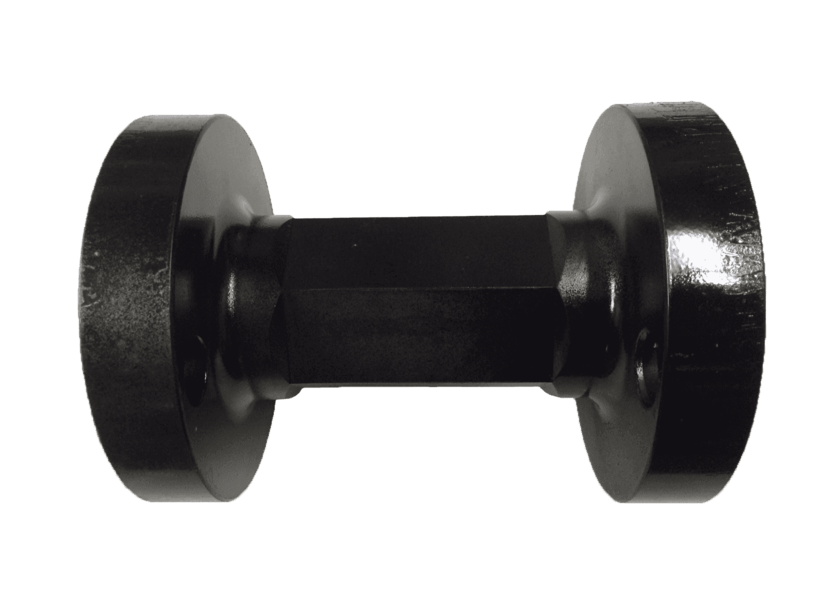

Main Concrete Piston:

The black, spool-shaped components are concrete pistons with dual sealing surfaces and a central bore for attachment to the piston rod. -

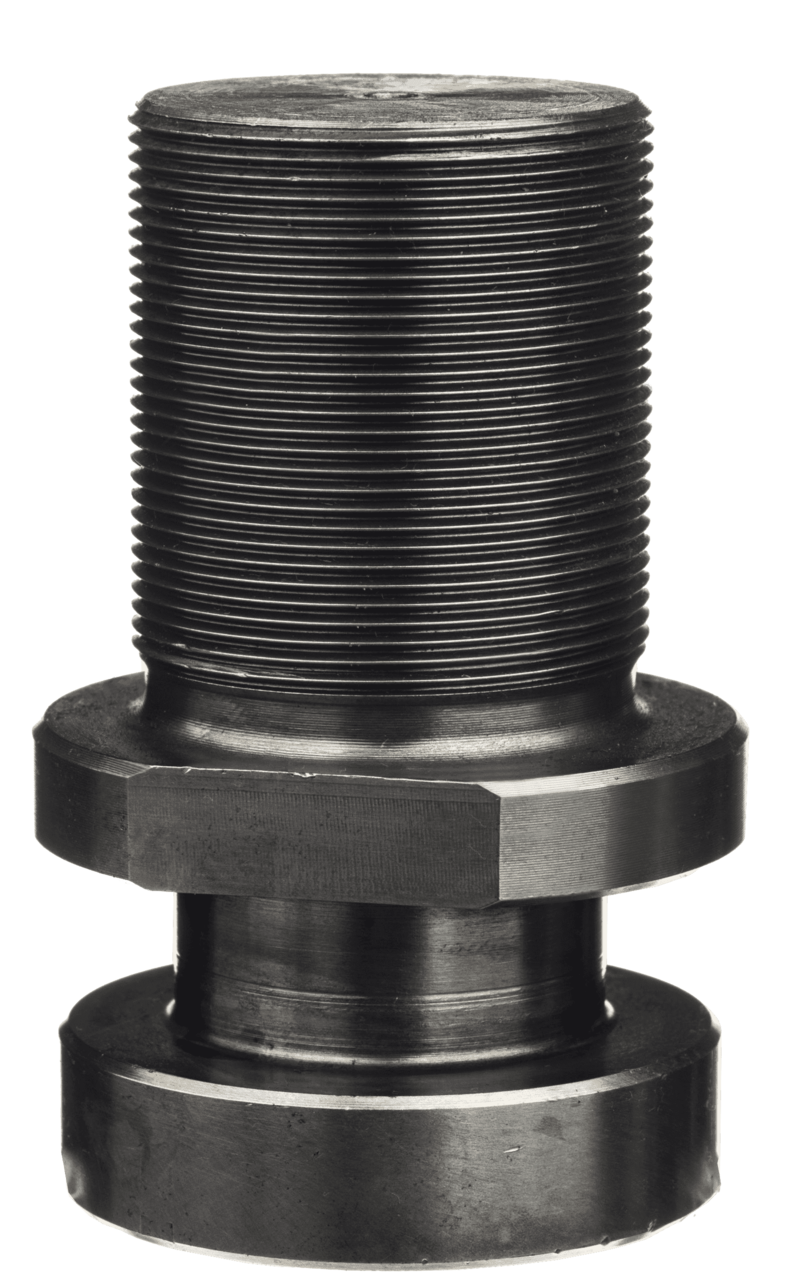

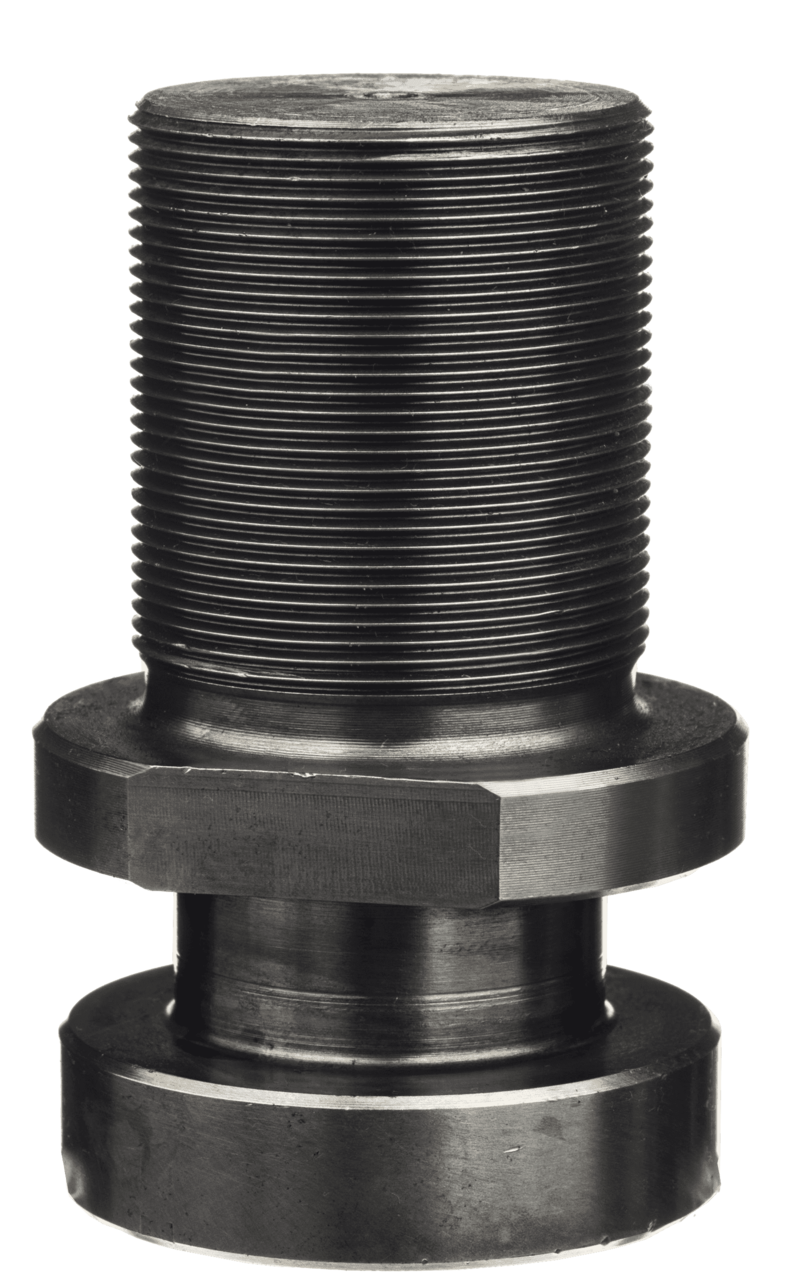

Threaded Shaft Component:

Likely a piston rod or part of a rod assembly, used to transmit force from the hydraulic actuator to the piston. -

Damaged or Worn Piston (Top-Center):

Possibly a used or worn example of a piston, illustrating typical wear zones. -

Rod with Surface Wear (Bottom-Left):

A piston rod, showing visible wear—an example of a replaceable wear item. -

Miscellaneous Views:

Alternate angles or designs of concrete pistons, demonstrating the variety in styles and sizes available for different pump models.

Additionals May Include:

-

Piston Rods: Precision-machined steel components that link the hydraulic system to the piston.

-

Guide Rings / Wear Rings: Components that guide the piston inside the cylinder and reduce metal-on-metal wear.

-

Sealing Rings / Back-Up Rings: Enhance sealing integrity and support piston performance under high pressure.

-

Fastening Hardware: Nuts, bolts, washers, and specialized fasteners used in piston assembly.

-

Lubrication Grooves / Grease Fittings: In some designs, additional elements may facilitate maintenance and reduce friction.

Ordering and Fitment Guidance:

To ensure correct part selection:

-

Confirm your Schwing pump model and serial number.

-

Reference the official Schwing parts manual or consult a certified dealer.

-

Measure the piston diameter, bore length, and attachment specs if part numbers are unavailable.

-

Identify the application environment (e.g., high-pressure usage, harsh concrete mixtures) to choose the most suitable material composition.

Note:

Concrete pistons are wear-critical components. Regular inspection and timely replacement are vital for maintaining optimal pumping performance and avoiding costly damage to the cylinder and hydraulic systems.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...