Putzmeister

Putzmeister® S Valves and Accessories Series for Concrete Pumps

Putzmeister® S Valves and Accessories Series for Concrete Pumps

The S Valves & Accessories Series is a critical assembly within Putzmeister® concrete pumps—especially models like the TXP 1021—ensuring smooth, reliable, and high-pressure delivery of concrete from hopper to delivery line. These components are engineered to withstand harsh conditions, high wear, and continuous mechanical operation, forming the heart of the pump's material transfer system.

🔧 Key Features & Benefits

-

Efficient Material Flow Diversion

The precision-engineered S-valve alternately connects each pumping cylinder to the delivery line, ensuring continuous and streamlined flow with minimal pressure drop or clogging. -

Wear Resistance

Critical components like the wear sleeves and valve linings are made of hardened steel or specialty composites to resist the abrasive nature of concrete. -

High-Pressure Tolerance

Designed to handle the intense pressures developed during the pumping cycle, ensuring dependable performance under heavy load. -

Reliable Operation

Delivers consistent switching between cylinders to maintain uninterrupted concrete output, reducing downtime and mechanical stress. -

Model-Specific Compatibility

Optimized for integration with Putzmeister® pumps—including the TXP 1021—with a range of sizes and specifications to meet different performance demands. -

Ease of Maintenance

Replaceable wear components and service-friendly designs help reduce maintenance time and increase uptime.

🧩 Component Overview (Based on Images)

-

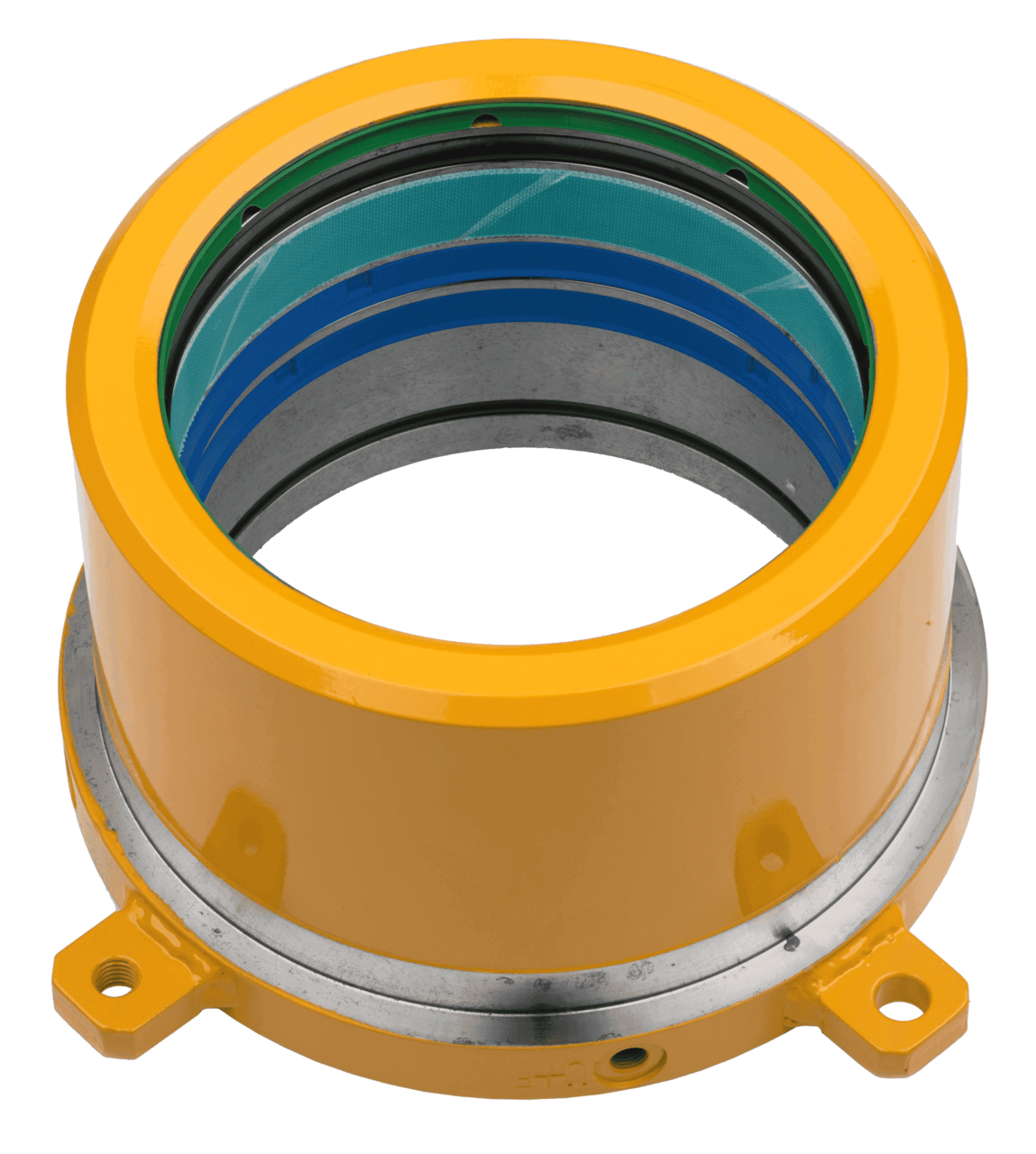

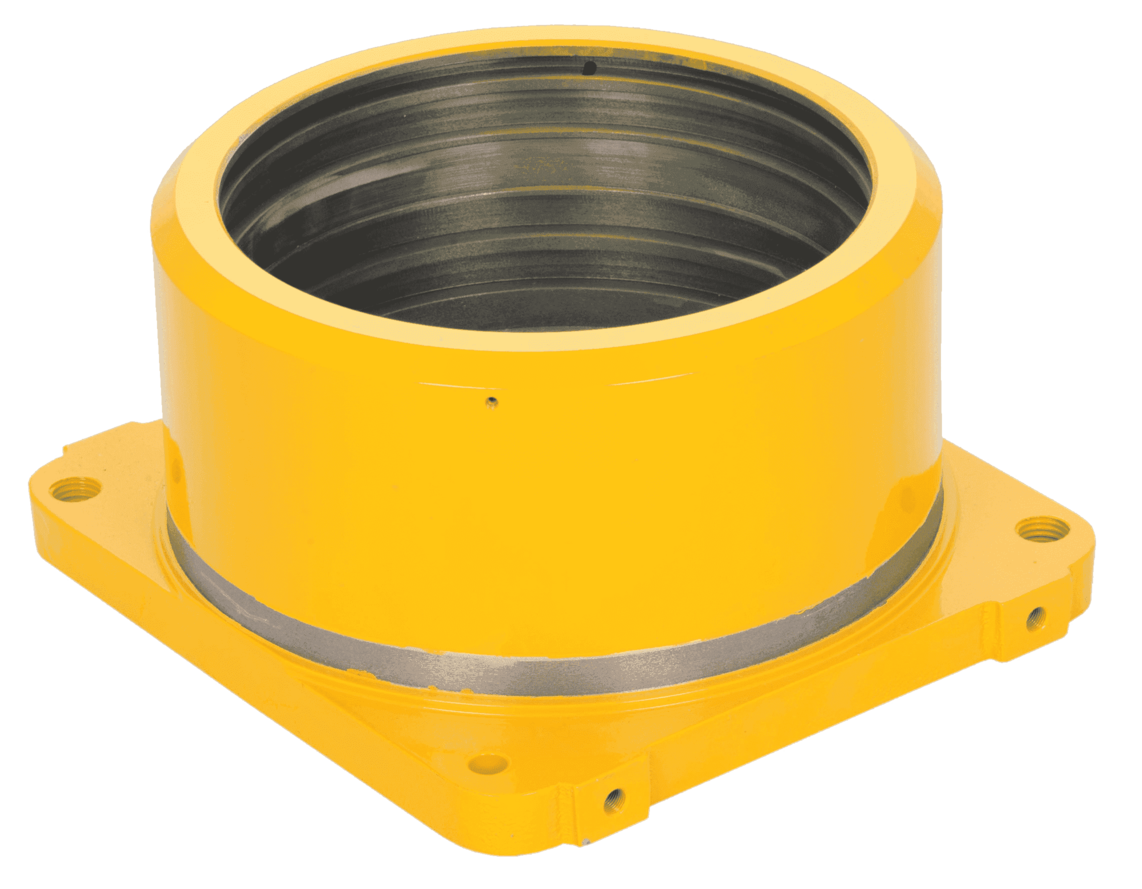

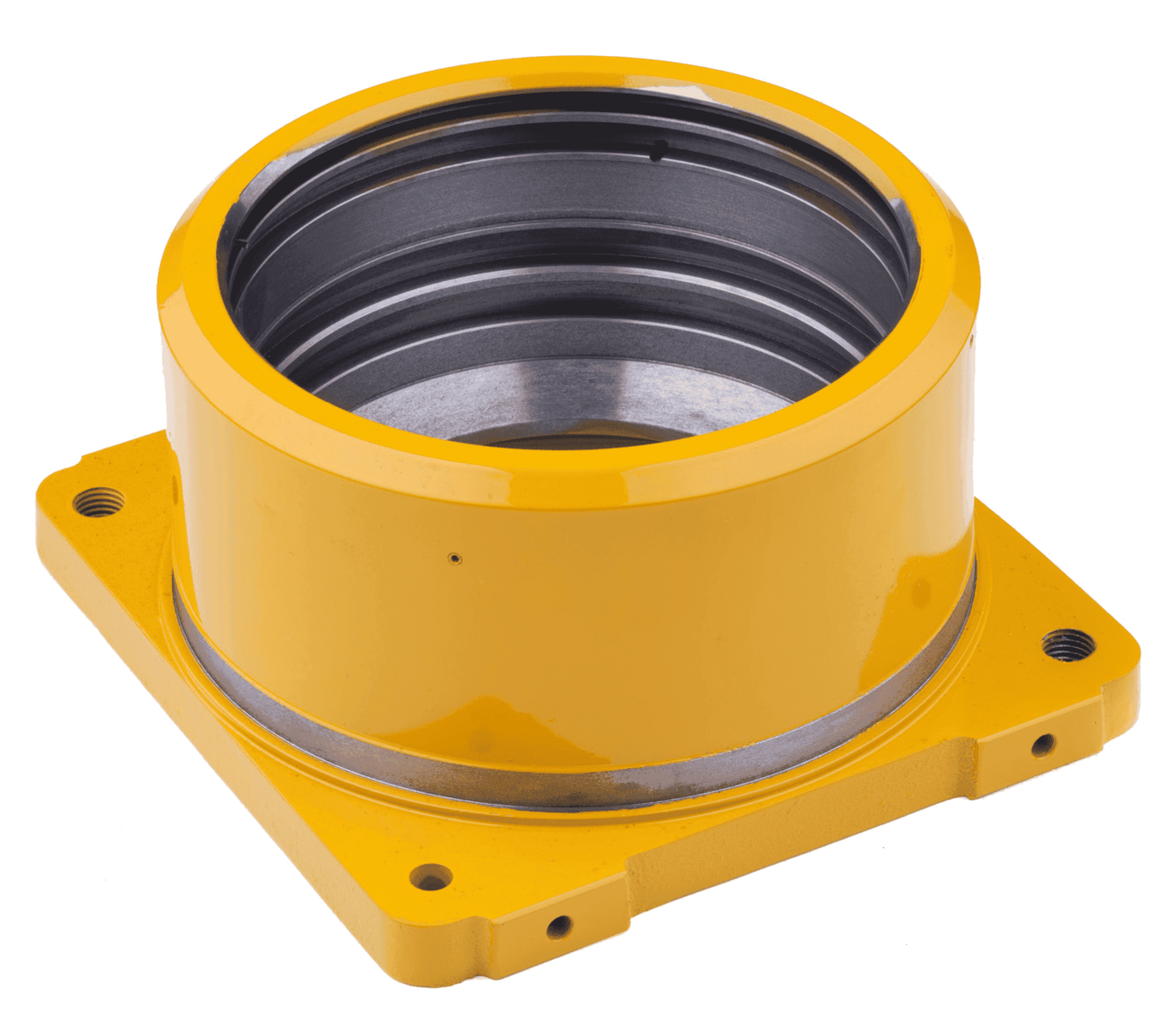

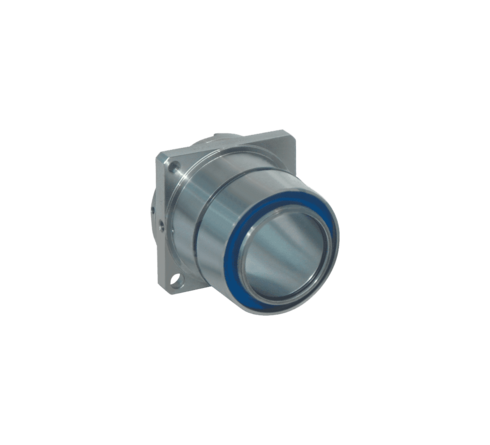

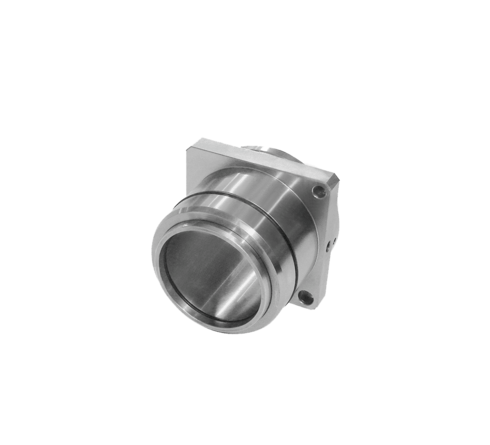

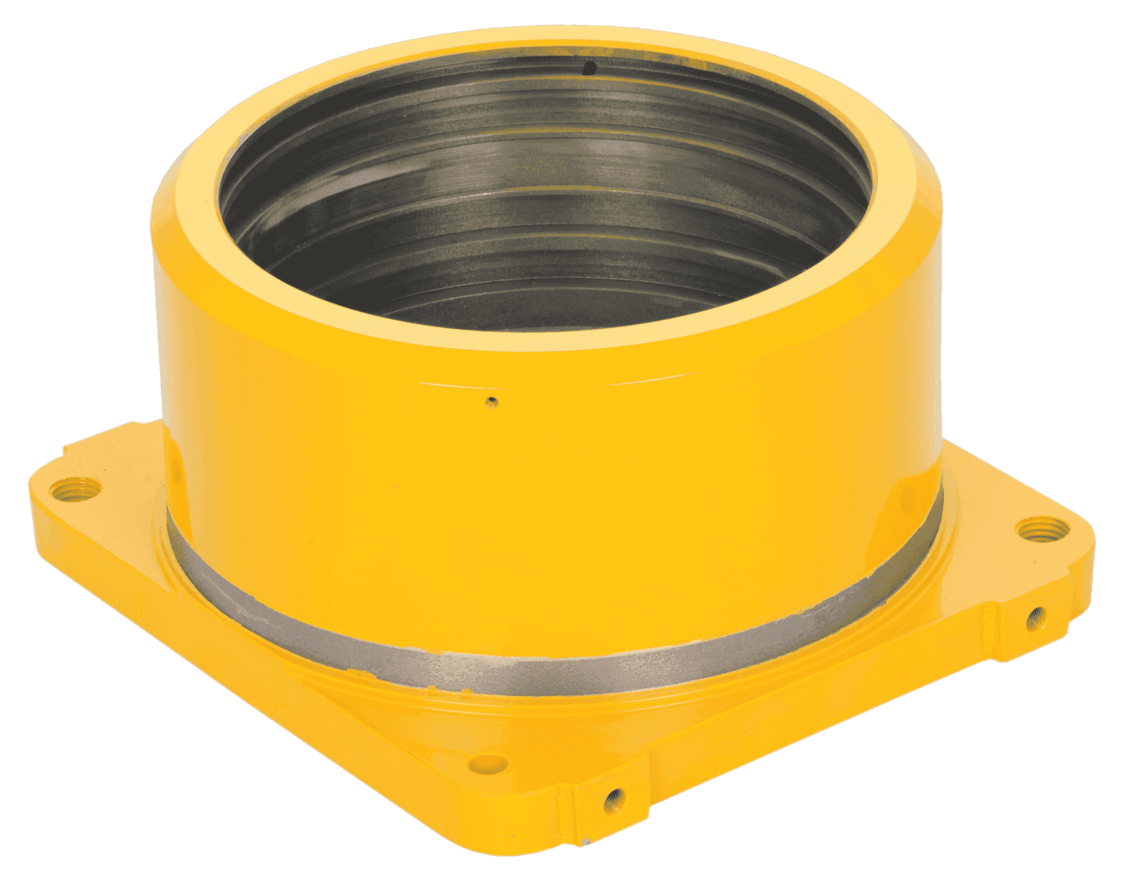

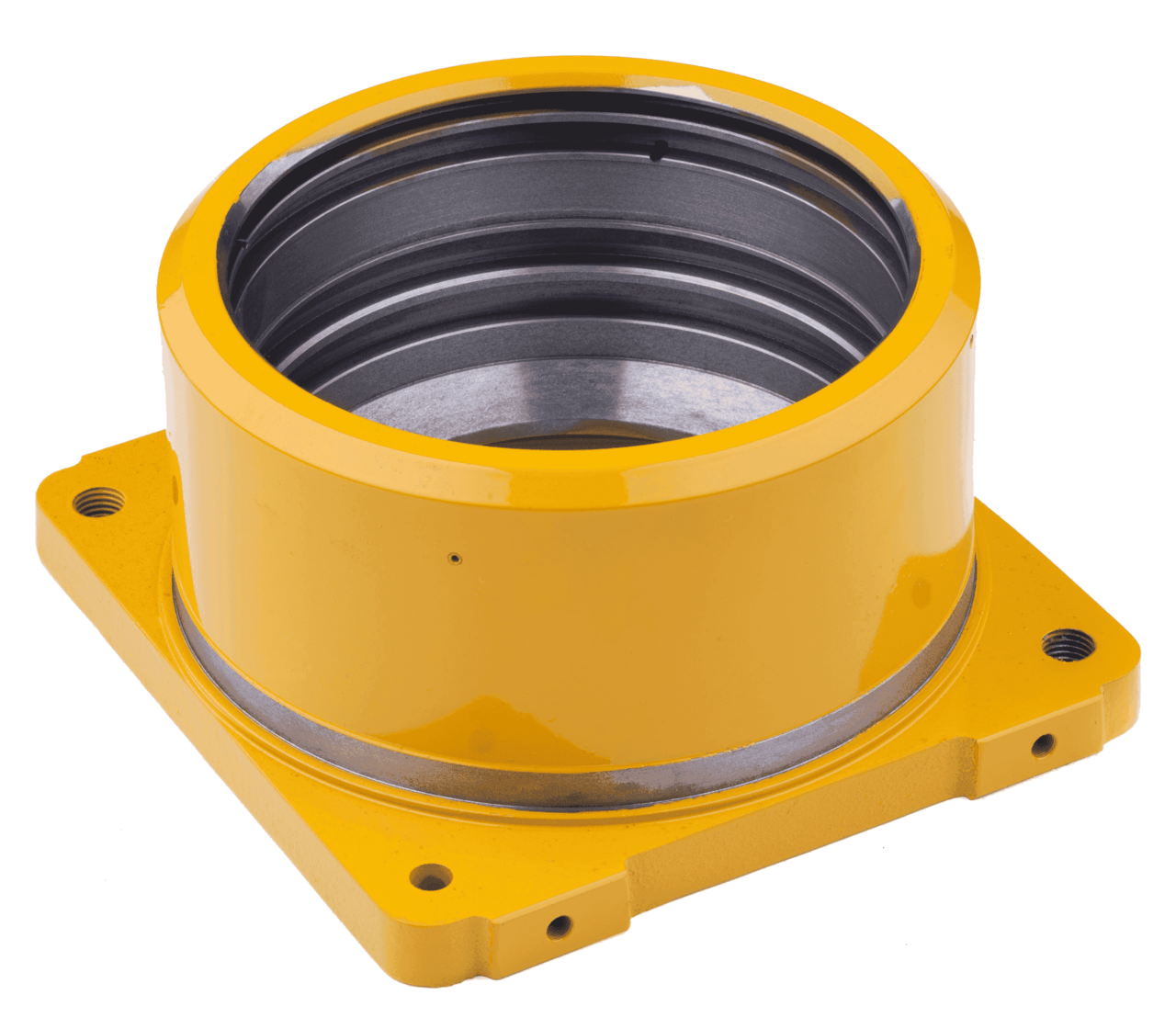

S-Valve Body (Yellow/Silver with Twin Ports):

The core diverter mechanism that swings between pumping cylinders. In TXP 1021, the S-valve is compact yet robust to handle consistent operation and high output. -

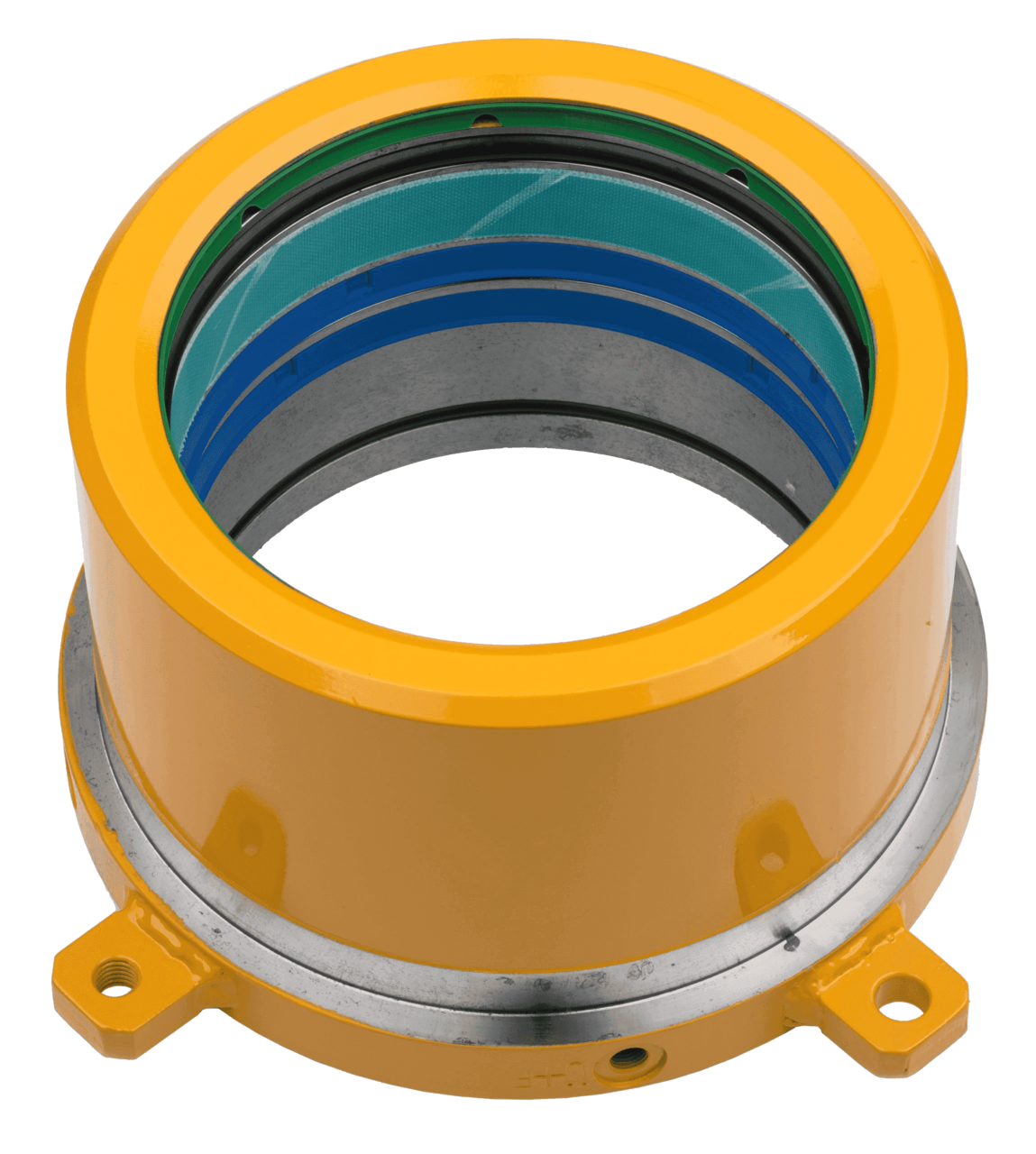

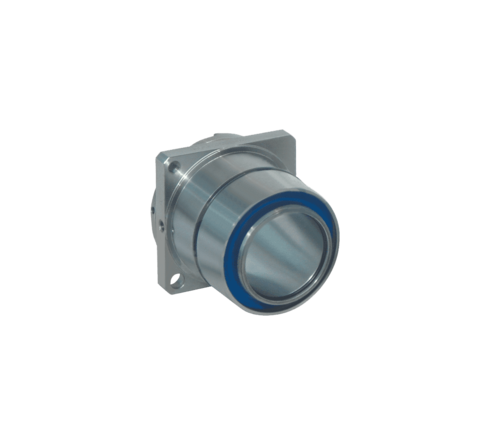

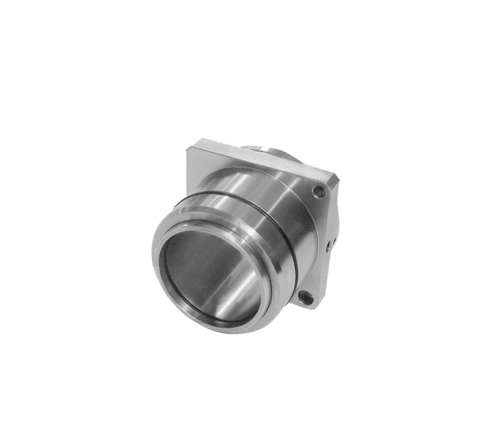

Wear Sleeves/Rings (Metal with Internal Coating):

These internal liners are exposed directly to concrete and are replaceable to protect the S-valve structure from erosion and wear. -

S-Valve Shaft (Steel Rods):

Supports the pivoting motion of the S-valve. Precision-fitted for durability and consistent swing action. -

Oscillating Mechanism Components (White/Metal Elements):

Likely part of the hydraulic actuator system that powers the S-valve’s side-to-side oscillation during pumping cycles. -

Seal Retainers (Metal Housings):

Prevent slurry leaks by securing seals around the S-valve body and shaft areas. -

Cylinder Liners (Silver Sleeves):

High-wear components lining the pump’s concrete cylinders. These protect the main body and ensure a tight fit for the piston stroke.

🏗️ S-Valve System Function – Including TXP 1021

1. Intake Phase:

The S-valve swings to open one pumping cylinder to the hopper, drawing in fresh concrete.

2. Delivery Phase:

At the same time, the other cylinder pushes concrete through the S-valve into the delivery line.

3. Oscillation:

Once the stroke is complete, the S-valve rapidly switches positions to repeat the cycle with the opposite cylinder.

This system ensures continuous concrete output, even though piston motion is reciprocating.

✅ Why It Matters for Your Concrete Pumping Operation

Especially in high-volume applications like those handled by the TXP 1021, the S-valve system is essential for:

-

Maintaining flow consistency and pressure

-

Preventing blockages and downtime

-

Ensuring adaptability to different aggregate sizes and mix designs

-

Extending the service life of major components

-

Supporting fast, high-efficiency delivery across construction sites in Burnaby and beyond

📘 Technical Reference & Part Selection

To ensure optimal performance and part compatibility—especially for the TXP 1021—refer to the official Putzmeister® parts catalog for:

-

Material specifications and wear part types

-

Component dimensions and tolerances

-

Installation and torque guidance

-

Maintenance intervals and inspection procedures

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...