Putzmeister

Putzmeister® Pumping Cylinders, Pistons and Accessories for Concrete Pumps

Putzmeister® Pumping Cylinders, Pistons and Accessories for Concrete Pumps

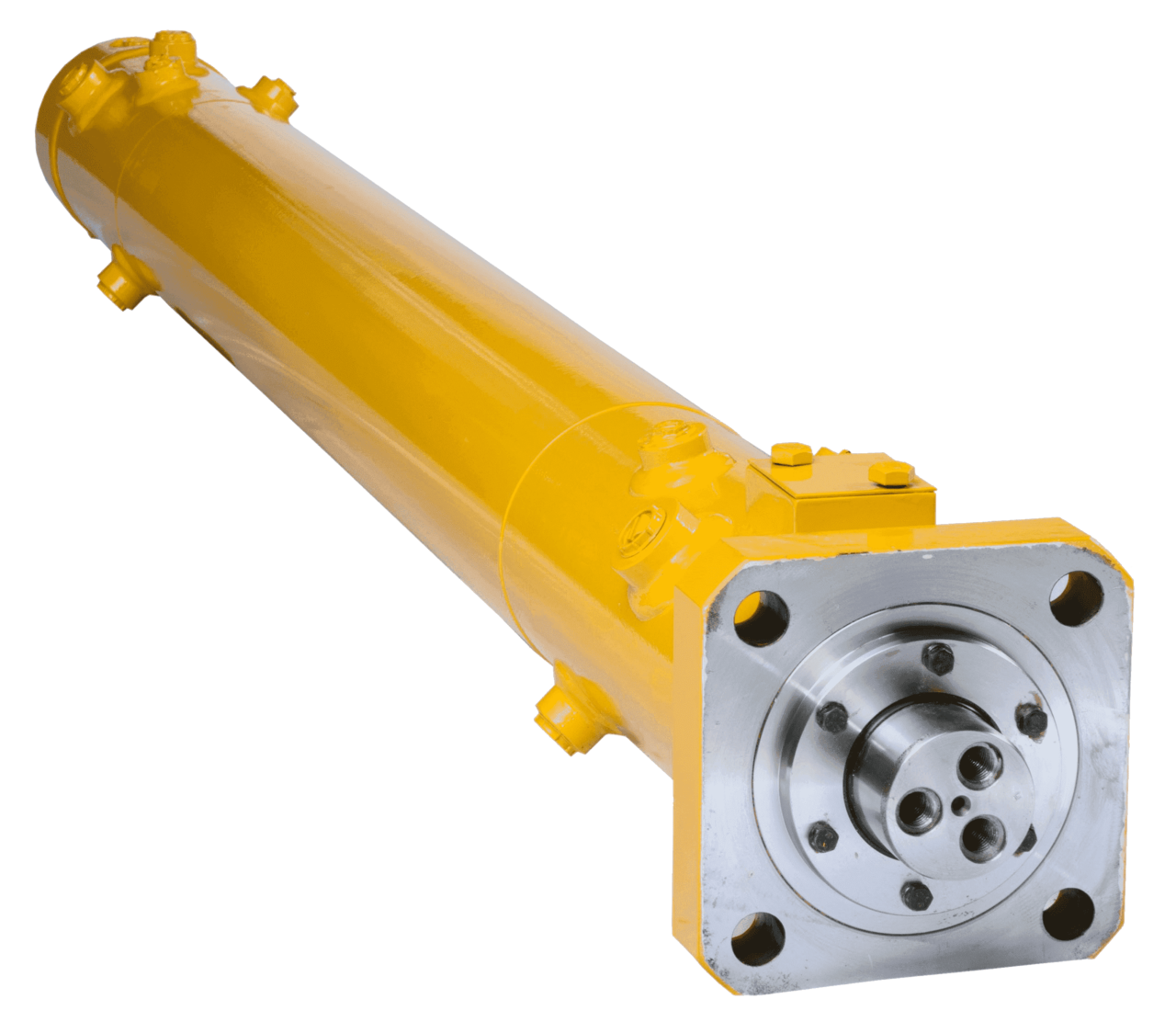

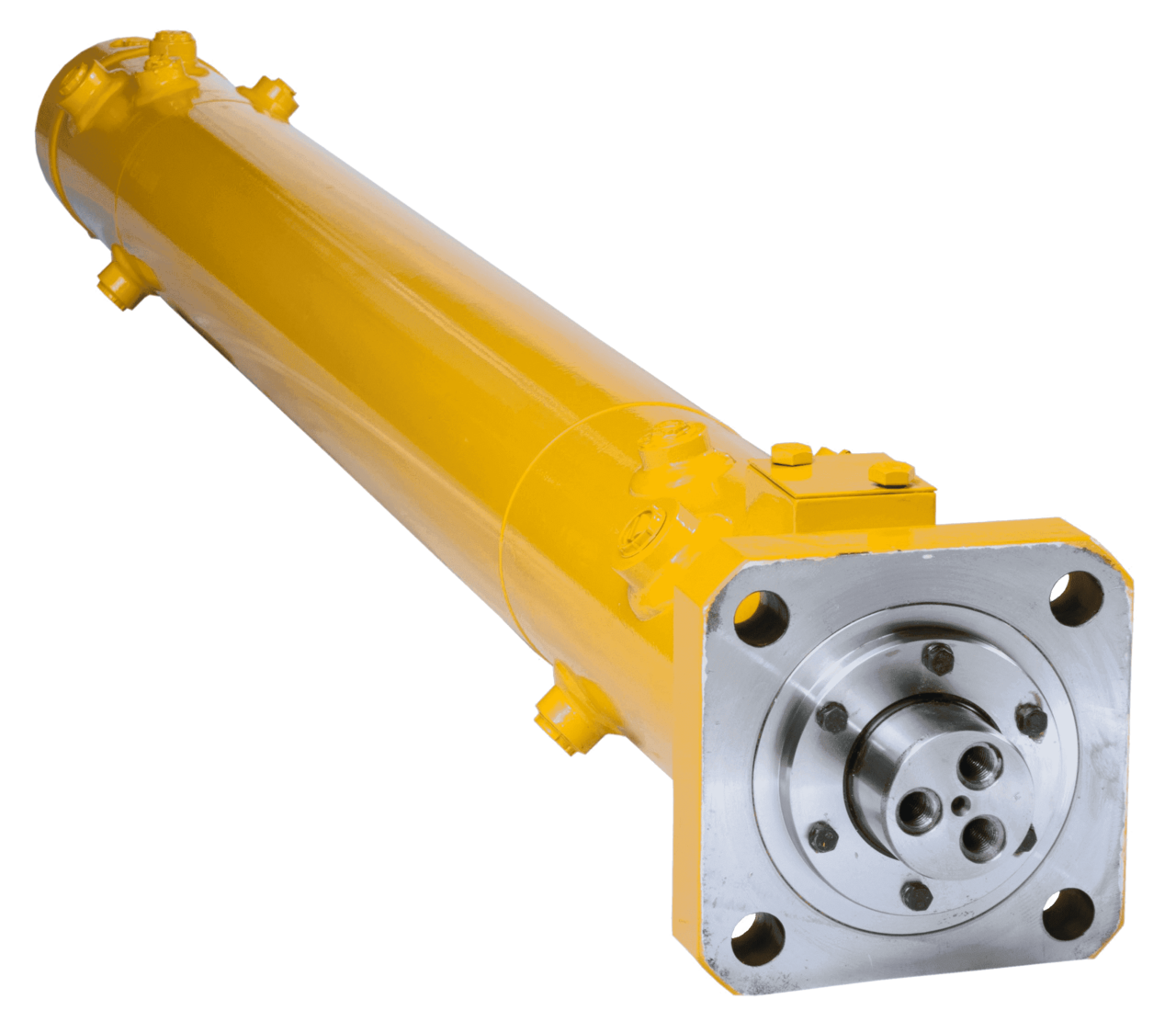

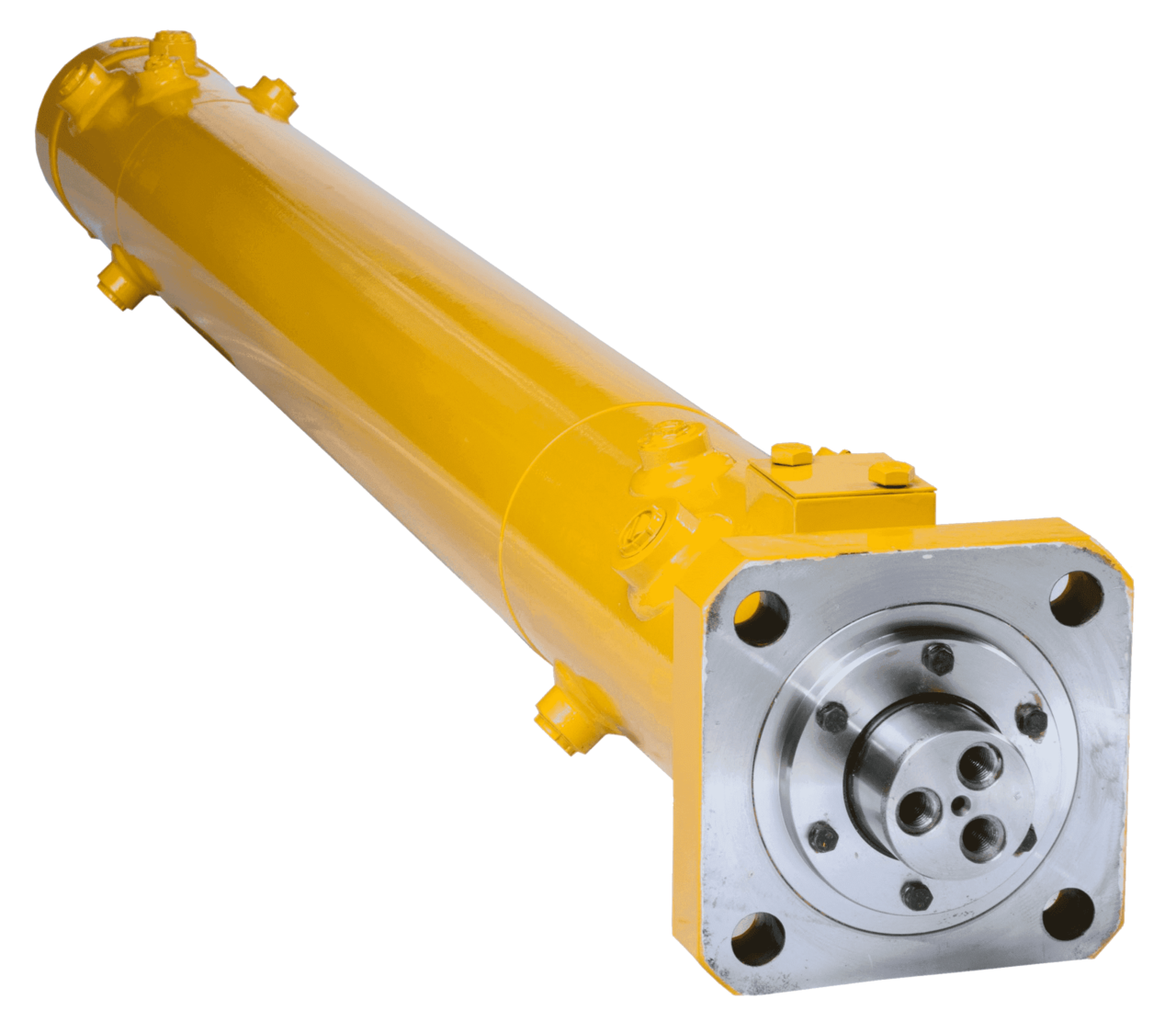

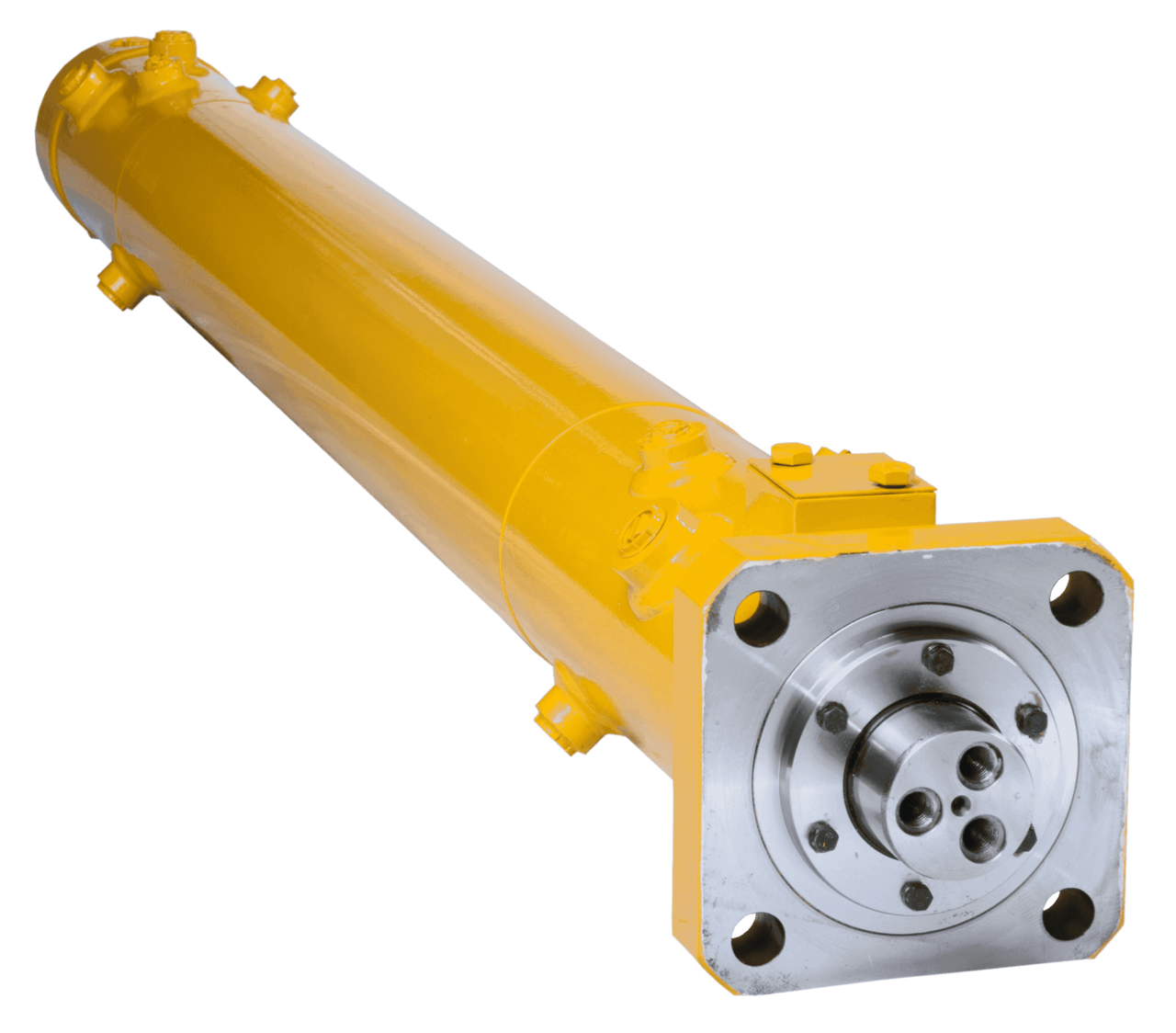

The Main Pumping Cylinders, Pistons, and Accessories Series for Putzmeister® concrete pumps includes the critical components responsible for drawing concrete from the hopper and forcefully delivering it into the pipeline. Designed for durability and performance, these high-precision parts are engineered to withstand the extreme pressures, abrasion, and duty cycles encountered in concrete pumping operations.

Crafted to meet or exceed OEM specifications, these components ensure reliable operation, consistent output, and long service life in even the most demanding environments.

Key Features & Benefits:

-

High-Pressure Performance:

Built to withstand the intense hydraulic forces generated during each pumping cycle. -

Superior Abrasion Resistance:

Piston heads and cylinder liners are hardened or surface-treated to resist wear from aggressive concrete mixes. -

Precision Fit & Sealing:

Equipped with high-quality seals and wear rings to prevent concrete blow-by and maintain efficient, leak-free performance. -

Optimized Piston Rod Guidance:

Guide bushings ensure accurate piston alignment, reducing lateral movement and wear on critical parts. -

Multiple Configurations Available:

Offered in various diameters and stroke lengths for compatibility with a wide range of Putzmeister® models. -

Heavy-Duty Construction:

Manufactured from high-strength steel and robust alloys to handle high-load, high-cycle applications. -

OEM-Compatible Design:

Fully compatible with OEM specifications for seamless integration into your Putzmeister® concrete pump.

Component Identification (Based on Image):

-

Main Pumping Cylinders (Yellow Tubes):

The core units where pistons reciprocate to intake and discharge concrete. -

Piston Rod Assembly (Red Component):

Transfers force from the hydraulic system to the piston head inside the cylinder. -

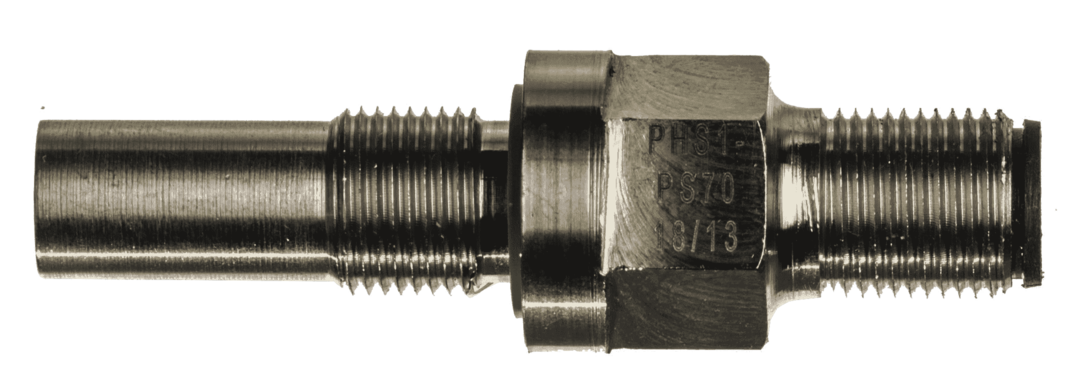

Guide Bush (Polished Steel Bushing):

Maintains piston rod alignment, prevents side loading, and protects the cylinder bore and seals. -

Cylinder Head / Flange (Dark Round Plate):

Seals the cylinder end and serves as a mounting interface for piston rods and bushings. -

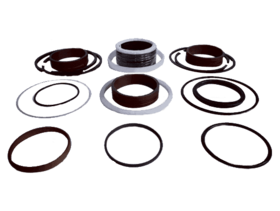

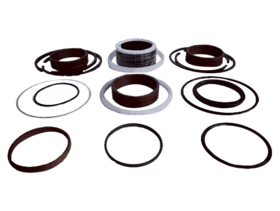

Seal Kit (O-Rings & Gaskets):

Includes all necessary dynamic and static seals to maintain pressure integrity and reduce leakage. -

Wear Ring & Guide Ring Set (Coiled Component):

Installed around the piston to minimize metal-on-metal contact and maintain axial alignment. -

Piston Component Stack (Polished Metal Stack):

Likely includes wear rings, piston heads, and other supporting elements for full piston assembly. -

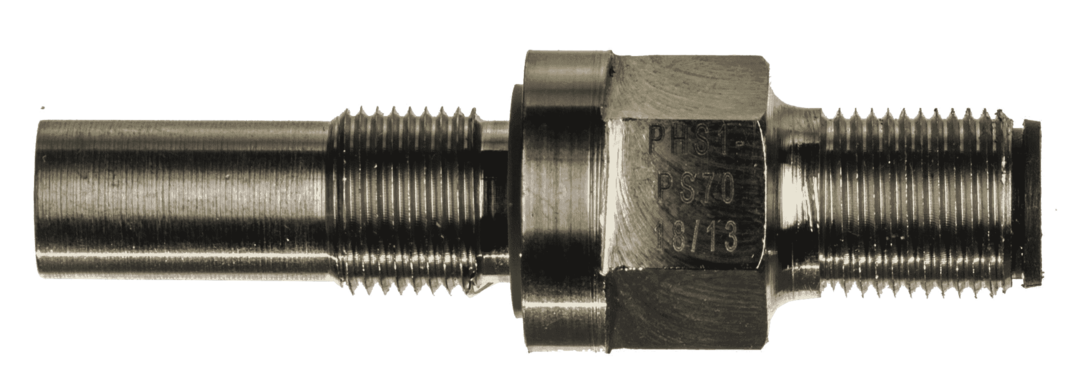

Connecting Rod Shaft (Threaded Shaft):

Transmits motion between the hydraulic cylinder and the pumping piston. -

Sensor Cable (Blue Cord):

Proximity or stroke position sensor used to monitor piston location for automated control systems.

Operational Role in Putzmeister® Pumps:

These components form the core of the concrete pumping system:

-

Intake Stroke:

The piston retracts, creating suction that draws concrete into the cylinder from the hopper. -

Delivery Stroke:

The piston advances, pushing concrete from the cylinder into the delivery line with high pressure.

The guide bush, seal kit, and wear components ensure this motion is smooth, efficient, and durable—minimizing downtime and maximizing throughput.

Why Choose OEM-Compatible Components?

-

Ensures peak pump performance and system integrity

-

Reduces maintenance costs and unexpected downtime

-

Enhances safety and productivity on the job site

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...