Putzmeister

Putzmeister® Oil Cooler System Parts for Concrete Pumps

Putzmeister® Oil Cooler System Parts for Concrete Pumps

The Oil Cooler System Parts Series for Putzmeister® concrete pumps includes a comprehensive range of components designed to manage the temperature of hydraulic oil within the pump's system. This critical system helps prevent overheating, ensuring the hydraulic fluid remains within optimal temperature ranges. By maintaining appropriate hydraulic oil viscosity, the system reduces component wear and enhances the longevity and performance of the pump, even during heavy use or in warmer climates.

Key Features & Benefits:

-

Efficient Heat Dissipation:

Oil coolers effectively transfer heat from the hydraulic oil to ambient air, preventing overheating and maintaining optimal operational temperatures. -

Stable Hydraulic Oil Viscosity:

Proper oil temperature ensures the hydraulic oil maintains the correct viscosity for efficient hydraulic operation and lubrication. -

Extended Component Life:

By preventing overheating, the oil cooler system safeguards pumps, motors, valves, and cylinders from premature wear, reducing the need for costly repairs and replacements. -

Consistent and Reliable Performance:

A well-regulated oil temperature ensures that the hydraulic system performs consistently under varying environmental conditions and operational demands. -

Comprehensive Component Selection:

The system includes high-efficiency oil coolers (heat exchangers), fans (both electric and hydraulic-driven), thermostats, temperature sensors, hoses, and fittings. -

Full Putzmeister® Compatibility:

Components are specifically engineered for seamless integration with Putzmeister® hydraulic systems, ensuring hassle-free operation and maintenance.

Component Overview

-

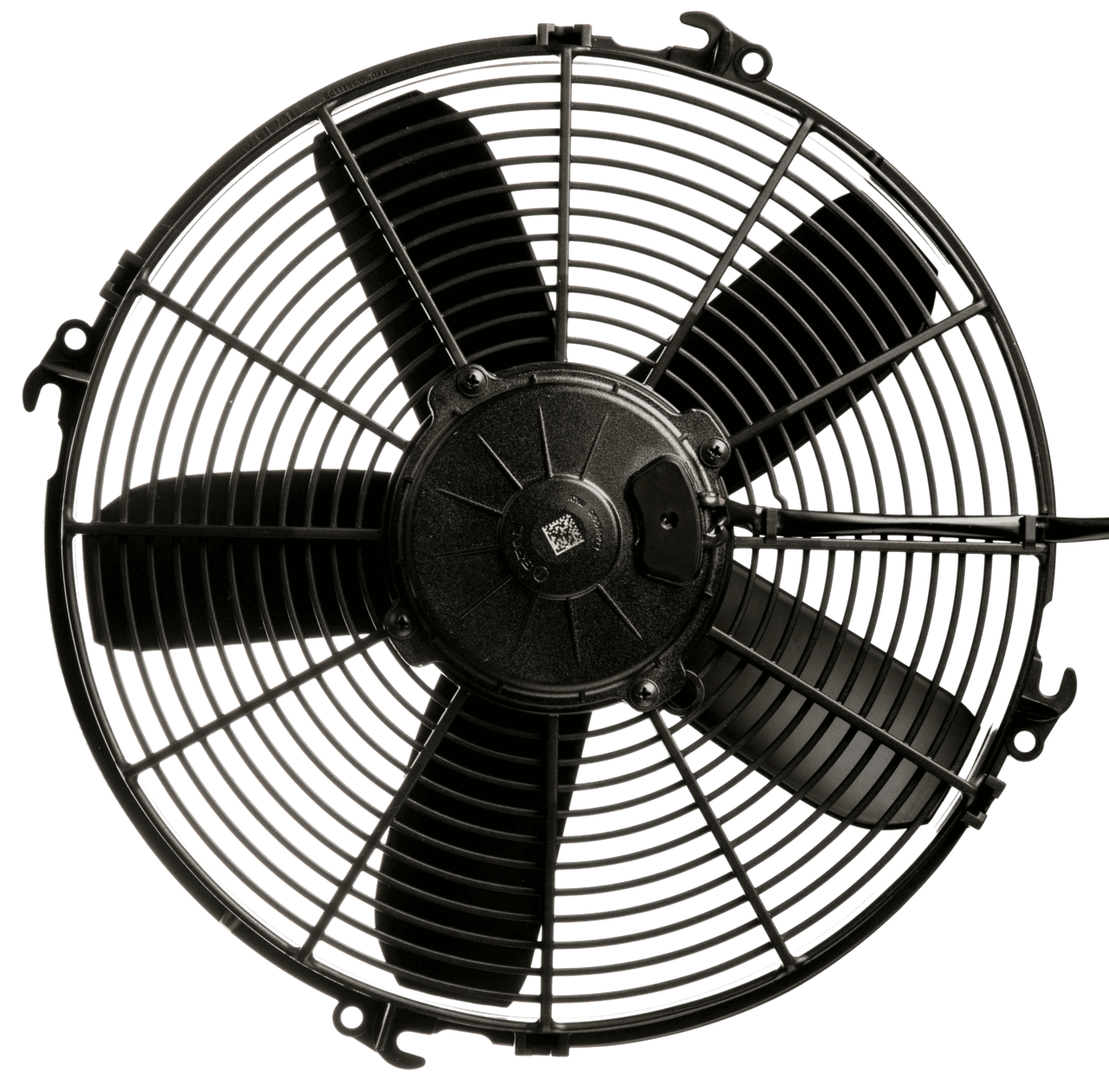

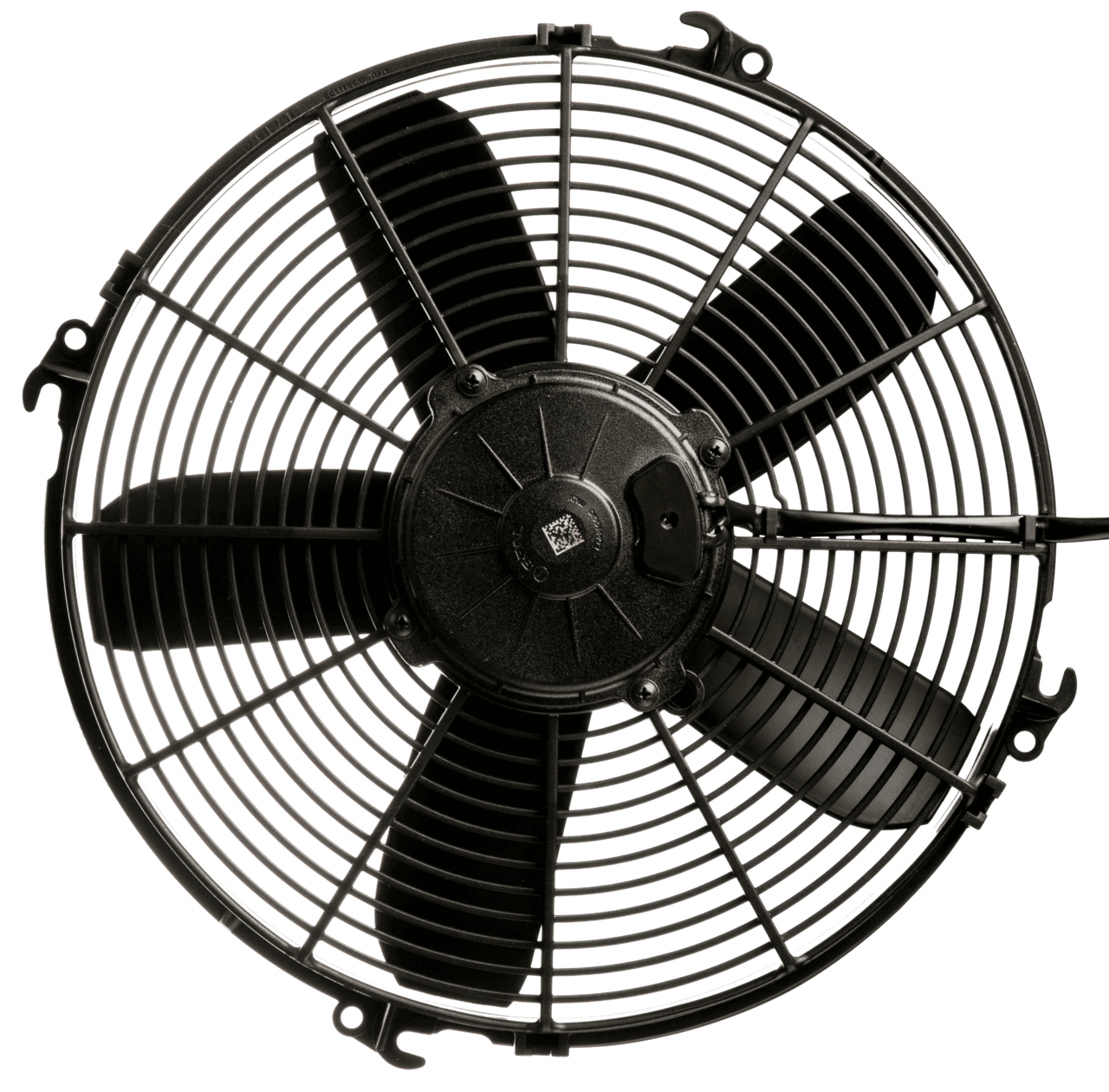

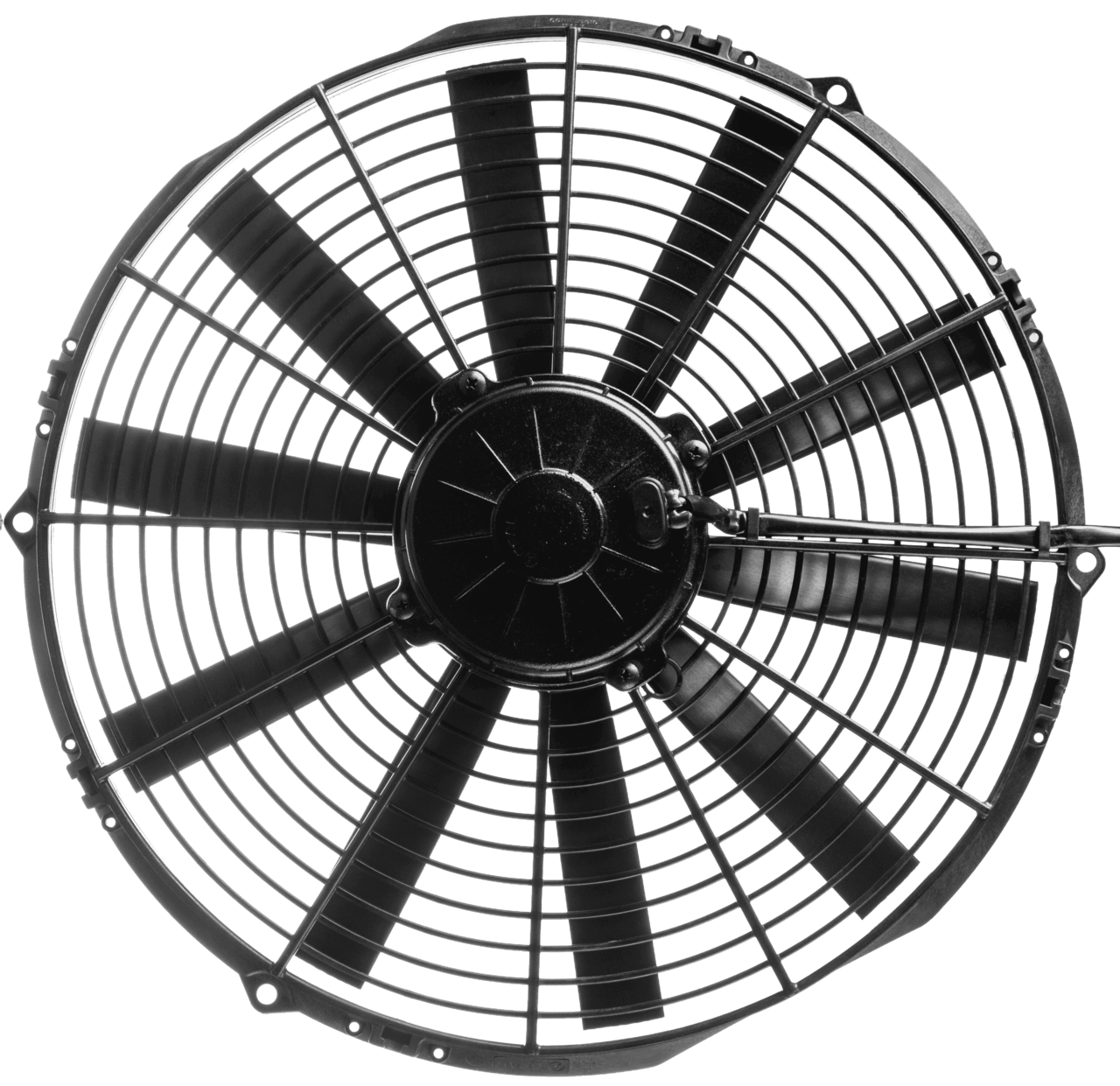

MEI Electric Puller Fan

Electrically powered fans that draw air through the oil cooler, increasing heat dissipation. These puller fans are mounted behind the cooler to enhance airflow. -

Fan Blades & Motor

Key components of the electric fan unit, responsible for drawing air through the cooling system. -

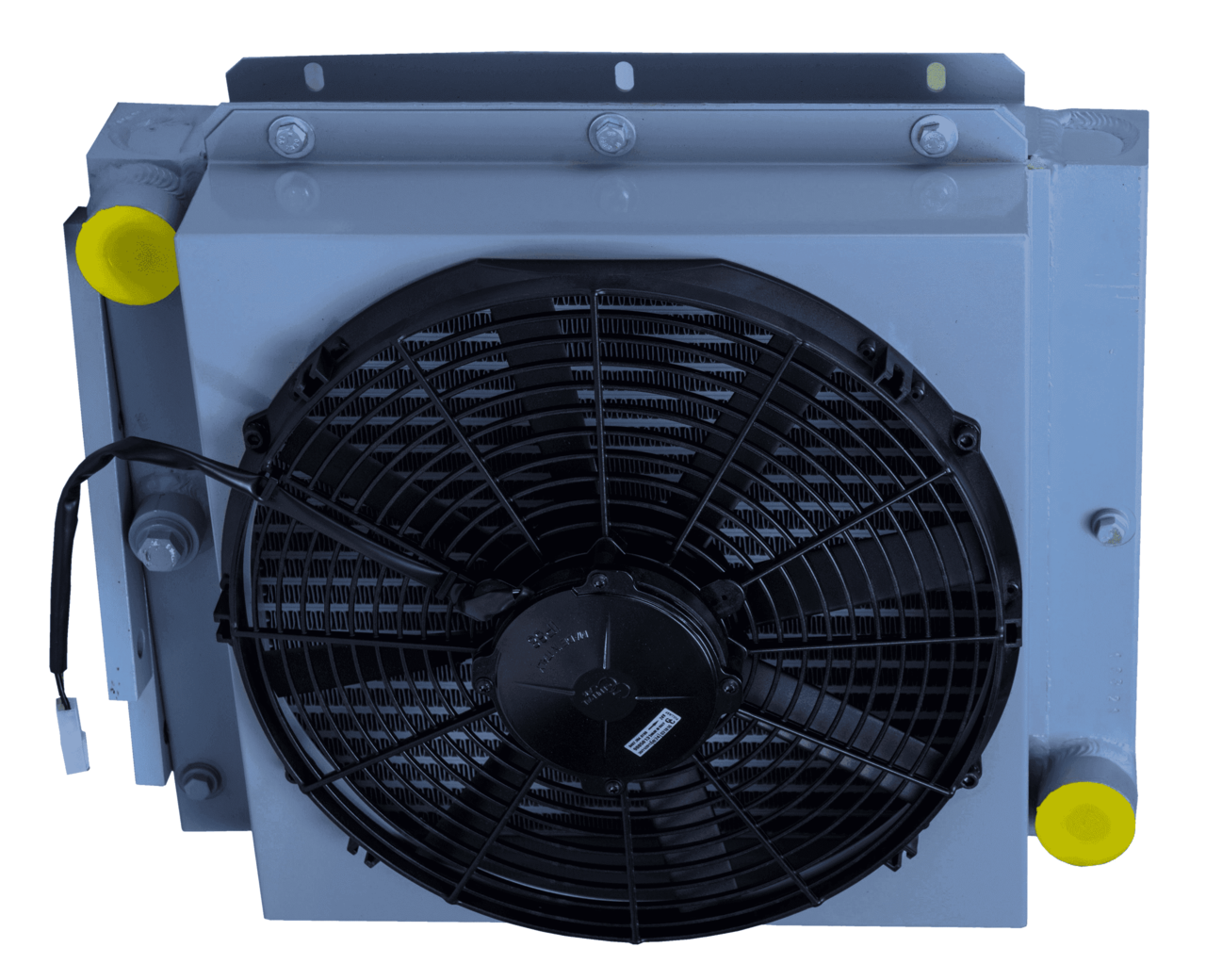

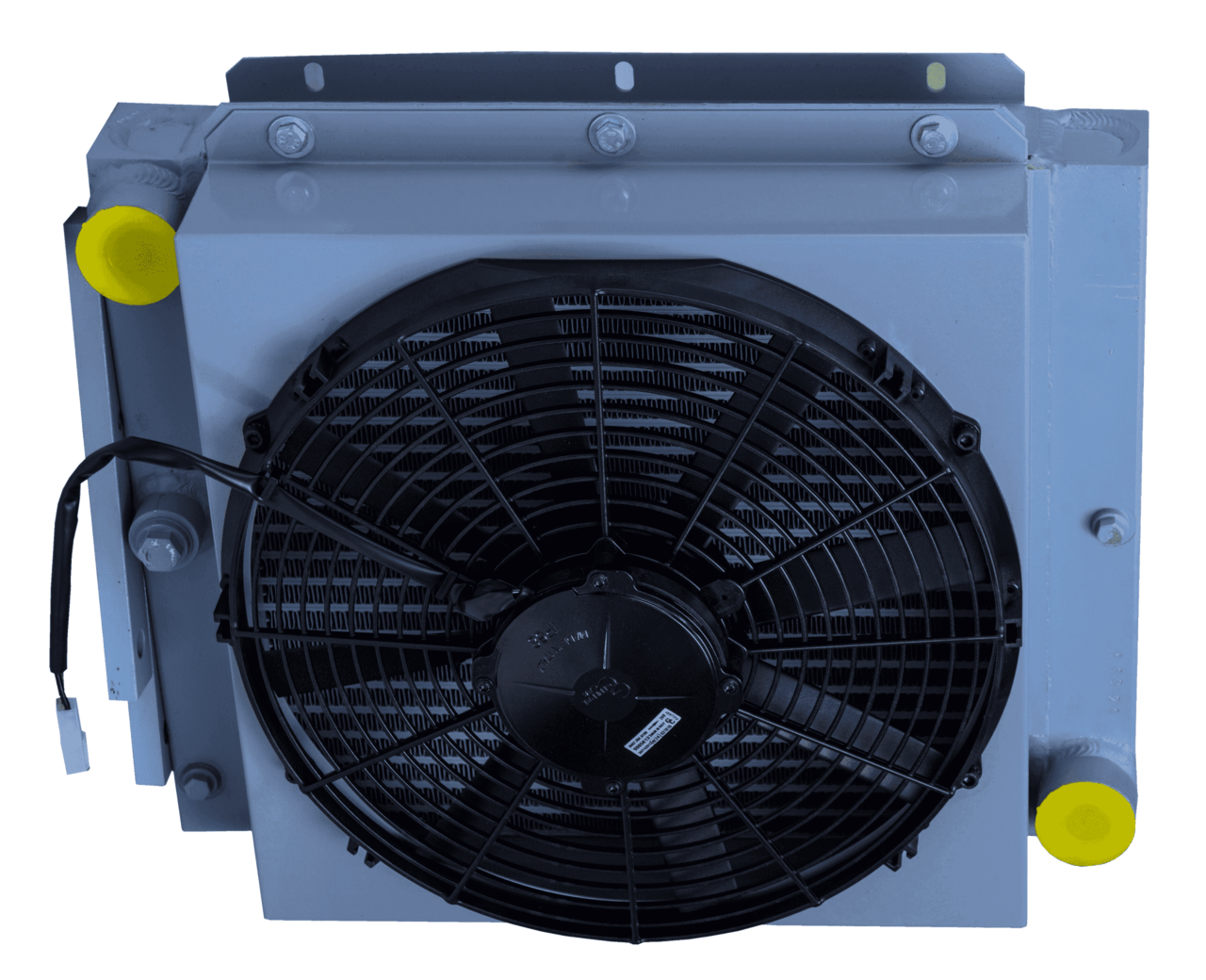

Oil Cooler Units

Heat exchangers equipped with fins that allow heat to transfer from the hydraulic oil to the passing air. These coolers may feature single or multiple fans depending on design. -

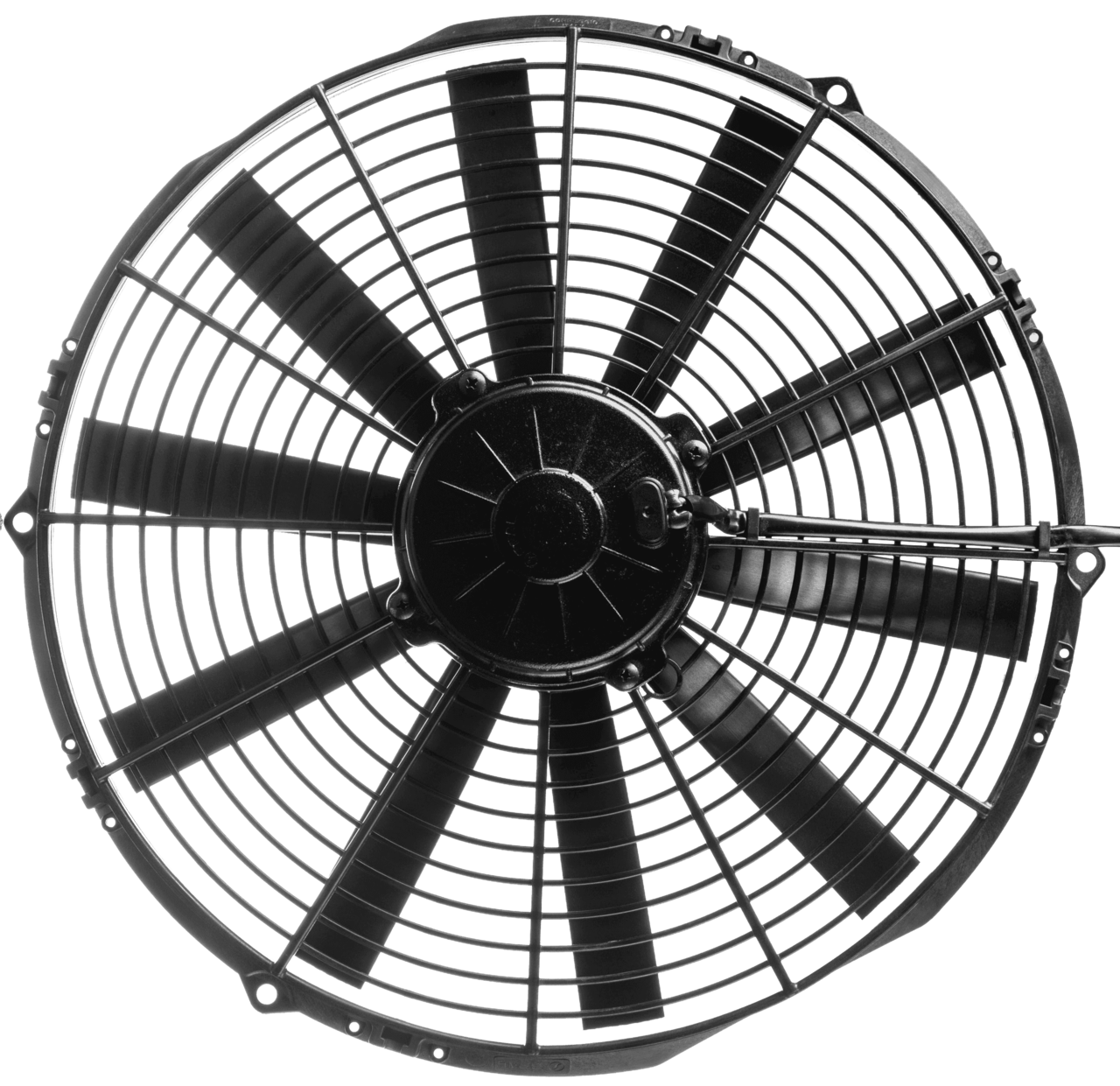

Fan Assemblies with Shrouds

Fans housed within shrouds that direct airflow efficiently through the oil cooler to maximize heat exchange. -

Hydraulic Fan Motor

A hydraulic motor used to power cooling fans, utilizing the pump's own hydraulic system to drive the fan, providing energy-efficient cooling.

Function within Putzmeister® Concrete Pumps:

The oil cooler system is essential for managing the temperature of the hydraulic fluid to ensure safe and efficient operation of the concrete pump:

-

Hydraulic Oil Circulation:

Hot hydraulic oil returns from the pump's hydraulic circuits and passes through the oil cooler to regulate temperature. -

Heat Exchange Process:

The cooler transfers heat from the hydraulic oil to the surrounding air, facilitated by the fan(s) which draw the air through the heat exchanger fins. -

Temperature Regulation:

Thermostats or temperature sensors monitor the hydraulic oil temperature and activate the fan(s) to maintain the desired temperature range.

Why It Matters:

A properly functioning oil cooler system is vital for:

-

Reliable Hydraulic Performance:

Prevents overheating, ensuring that the hydraulic system performs smoothly under all conditions. -

Protection of Hydraulic Components:

Prevents damage to key hydraulic components, extending the lifespan of critical parts and avoiding costly maintenance. -

Optimized Pump Efficiency:

Ensures hydraulic oil maintains proper viscosity for effective power transmission, optimizing the concrete pumping process.

Get the Right Parts for Your Pump:

For detailed specifications on specific Putzmeister® Oil Cooler System Parts, including fan models (such as the MEI Electric Puller Fan), oil cooler dimensions, heat exchange capacities, and compatibility with different pump models, we recommend consulting the official Putzmeister® parts catalogs and technical documentation. Ensuring your oil cooler system is well-maintained with the correct components is key to the consistent and reliable performance of Putzmeister® concrete pumps, particularly during demanding jobs and varying temperatures throughout the year.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...