Putzmeister

Putzmeister® Mixer Shafts and Washers Series for Concrete Pumps

Putzmeister® Mixer Shafts and Washers Series for Concrete Pumps

The Mixer Shafts & Washers Series for Putzmeister® concrete pumps includes the essential components that power the mixing mechanism inside the hopper. These high-strength rotating shafts, paired with durable washers and mounting hardware, are engineered to support and drive the mixing paddles that continuously agitate concrete—preventing aggregate segregation and maintaining workability.

Precision-engineered to OEM specifications, these components ensure optimal performance, reliability, and extended service life in the demanding conditions of concrete handling and pumping.

Key Features & Benefits:

-

Consistent Mixing Performance:

Designed to promote thorough and continuous agitation, ensuring homogenous concrete for smooth pumping and placement. -

Heavy-Duty Construction:

Crafted from high-tensile steel to resist wear, deformation, and torsional stress during operation. -

Exact Fit & Alignment:

Manufactured to match Putzmeister® original dimensions for easy installation and superior performance in any compatible hopper setup. -

Corrosion & Abrasion Resistance:

Treated with protective finishes to resist damage from moisture, cementitious materials, and harsh environmental conditions. -

Variety of Models & Configurations:

Available in multiple shaft lengths, diameters, and paddle-mounting designs to suit a wide range of Putzmeister® mixer assemblies. -

Secure Paddle Attachment:

Includes rugged washers and fasteners that ensure paddles remain firmly affixed to the shaft, even under continuous load and vibration. -

Full OEM Compatibility:

Engineered for seamless integration with Putzmeister® hopper assemblies and hydraulic or electric mixer drive systems.

Component Overview (Based on Image):

-

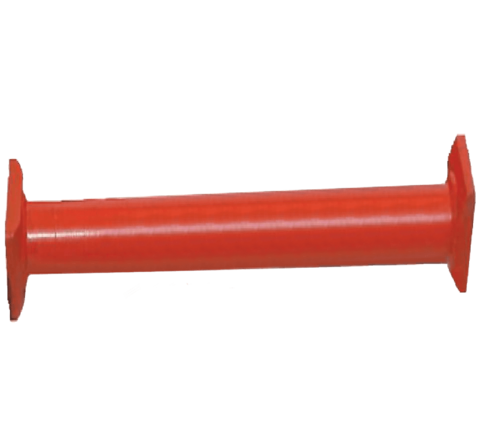

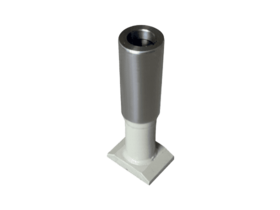

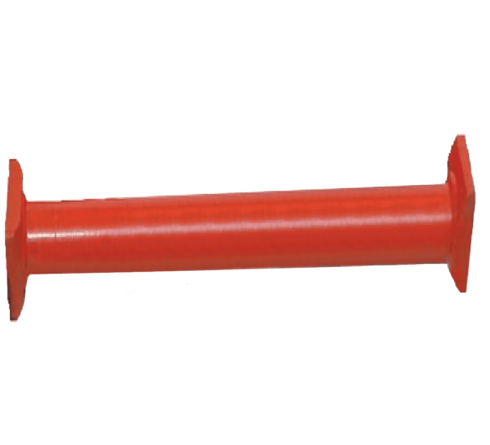

Mixer Shafts (Silver Cylindrical Units with Mounts):

Central rotating components to which paddles are bolted. Feature flanged bases for secure mounting to the hopper structure. -

Colored Shaft Variants (Yellow & Red):

Likely represent mixer shaft variants for different pump models or custom paddle configurations. May differ in size, connection type, or load capacity. -

Washer Sets (Metal Discs):

Used to lock paddles onto the shaft and prevent axial movement. May be separate hardware or integrated into the shaft design as flanges or shoulders.

Operational Role in Putzmeister® Pumps:

The mixer shafts and washers play a vital role in the pre-pumping phase by ensuring the concrete mix remains uniform and pumpable:

-

Mixing:

The shafts support paddles that churn the concrete within the hopper to prevent material separation. -

Rotation Transfer:

Power from the mixer motor is transferred through the shaft to the paddles, ensuring consistent motion and energy distribution. -

Paddle Stability:

Washers and securing mechanisms keep paddles tightly attached to the shaft, even under high torque and continuous movement.

Why It Matters:

A well-functioning mixer shaft system is critical to the success of concrete delivery:

-

Maintains Pumpable Mix Consistency

-

Prevents Blockages & Flow Interruptions

-

Reduces Wear on Pumping Components

-

Improves On-Site Efficiency and Quality Control

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...