Putzmeister

Putzmeister® Hydraulic Motors and Pumps Series for Concrete Pumps

Putzmeister® Hydraulic Motors and Pumps Series for Concrete Pumps

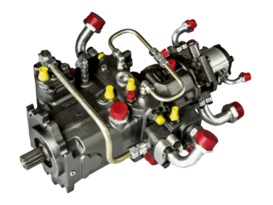

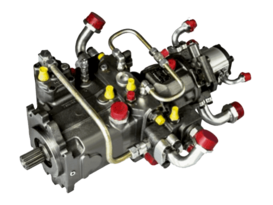

The Hydraulic Motors & Pumps Series for Putzmeister® concrete pumps delivers the muscle behind every critical movement of the pump. These components are purpose-built to deliver reliable, high-efficiency performance across the full spectrum of hydraulic functions—from main concrete pumping to boom articulation, agitator mixing, outrigger stabilization, and auxiliary operations.

Key Features & Benefits:

-

Efficient Power Conversion

Hydraulic pumps transform mechanical energy into hydraulic pressure with minimal energy loss, while motorsconvert hydraulic energy back into mechanical motion—powering critical systems like the boom, agitator, and water pump. -

Reliable, Heavy-Duty Operation

Engineered for continuous use in high-demand environments, these components maintain performance under pressure—literally. -

Range of Types and Configurations

Choose from axial piston pumps and motors, gear pumps and motors, and radial piston motors to match the torque, pressure, and flow requirements of your system. -

Durable, Rugged Construction

Built with wear-resistant materials and precision-machined components to handle the intense pressures and dirty working conditions of concrete pumping. -

Precise Speed & Torque Control

Motors offer controlled rotational output for boom placement and agitator mixing, while variable displacement pumps allow for flow modulation to match operational needs. -

Putzmeister® OEM Compatibility

Designed for direct integration into Putzmeister® hydraulic systems, ensuring seamless operation and optimal performance.

Common Components in the Series:

-

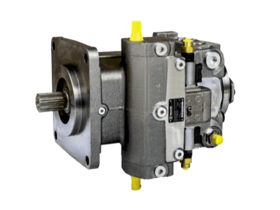

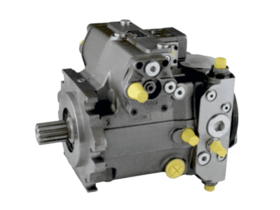

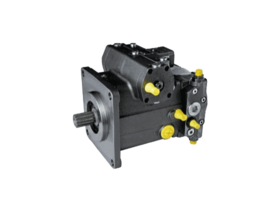

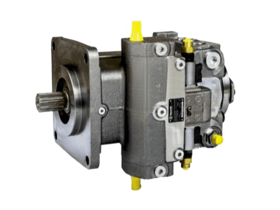

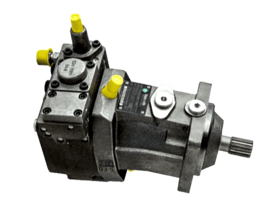

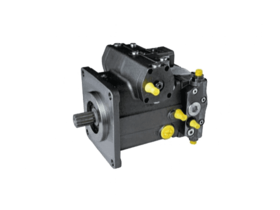

Axial Piston Pumps

High-efficiency, high-pressure pumps—often variable displacement—for delivering primary hydraulic power to the main pumping cylinders. -

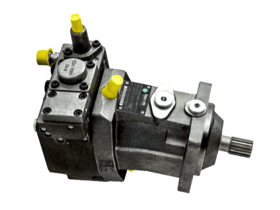

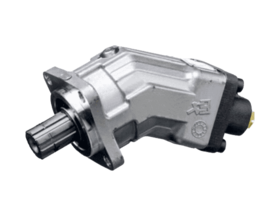

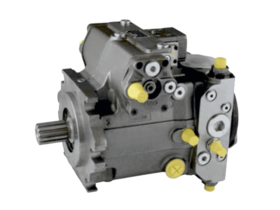

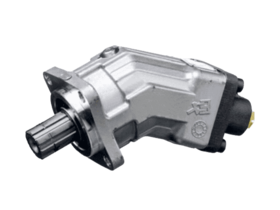

Axial Piston Motors

Used in boom swing, agitator drive, and other demanding applications requiring high efficiency and continuous duty cycles. -

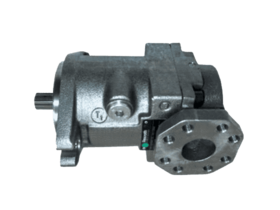

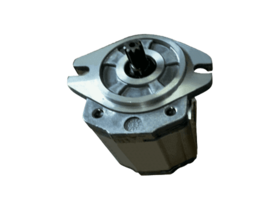

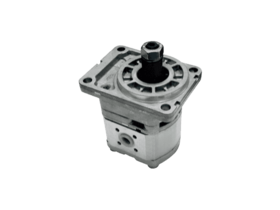

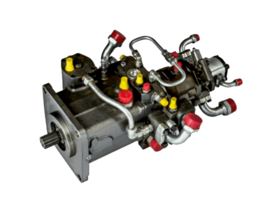

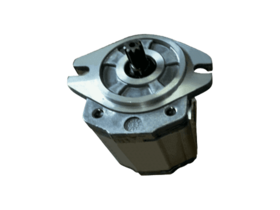

Gear Pumps

Simple, compact, and cost-effective—ideal for lower-pressure systems such as auxiliary hydraulics or pilot controls. -

Gear Motors

Provide consistent torque at lower speeds—great for secondary drive functions in rugged environments. -

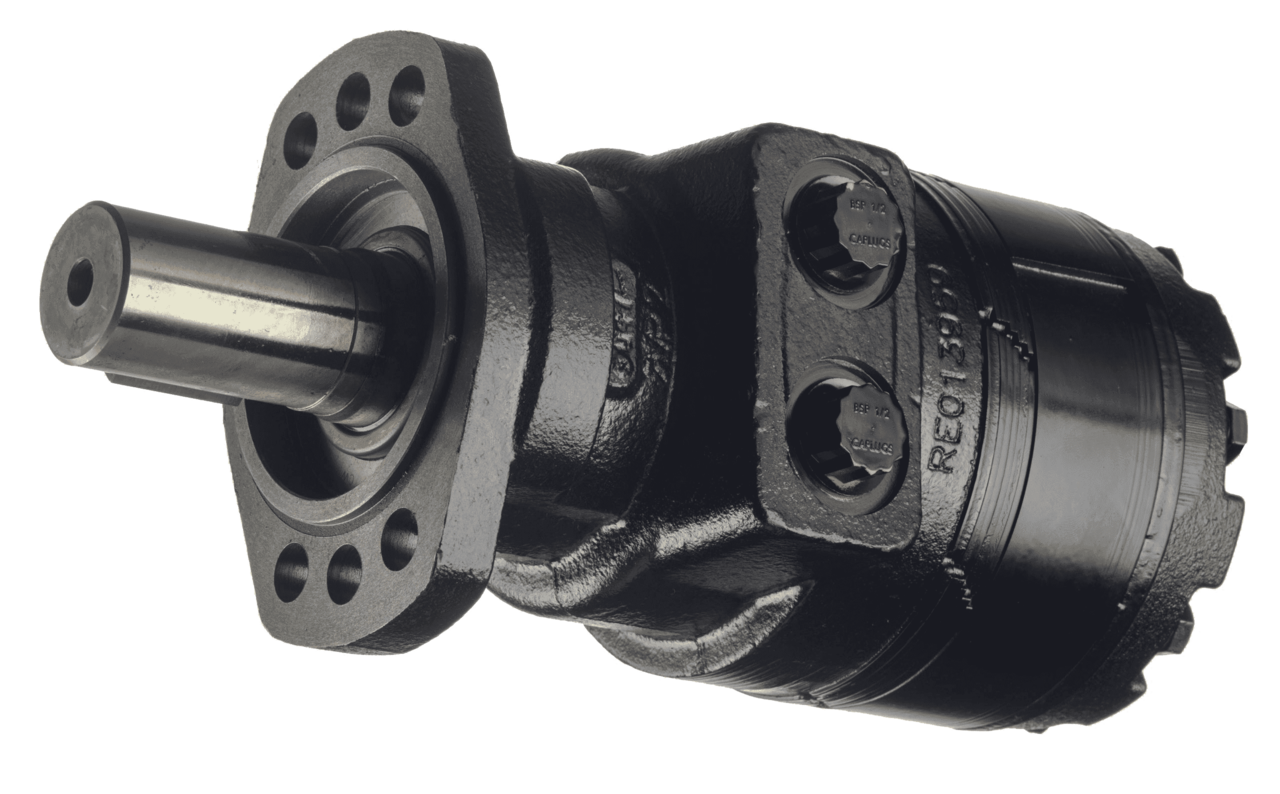

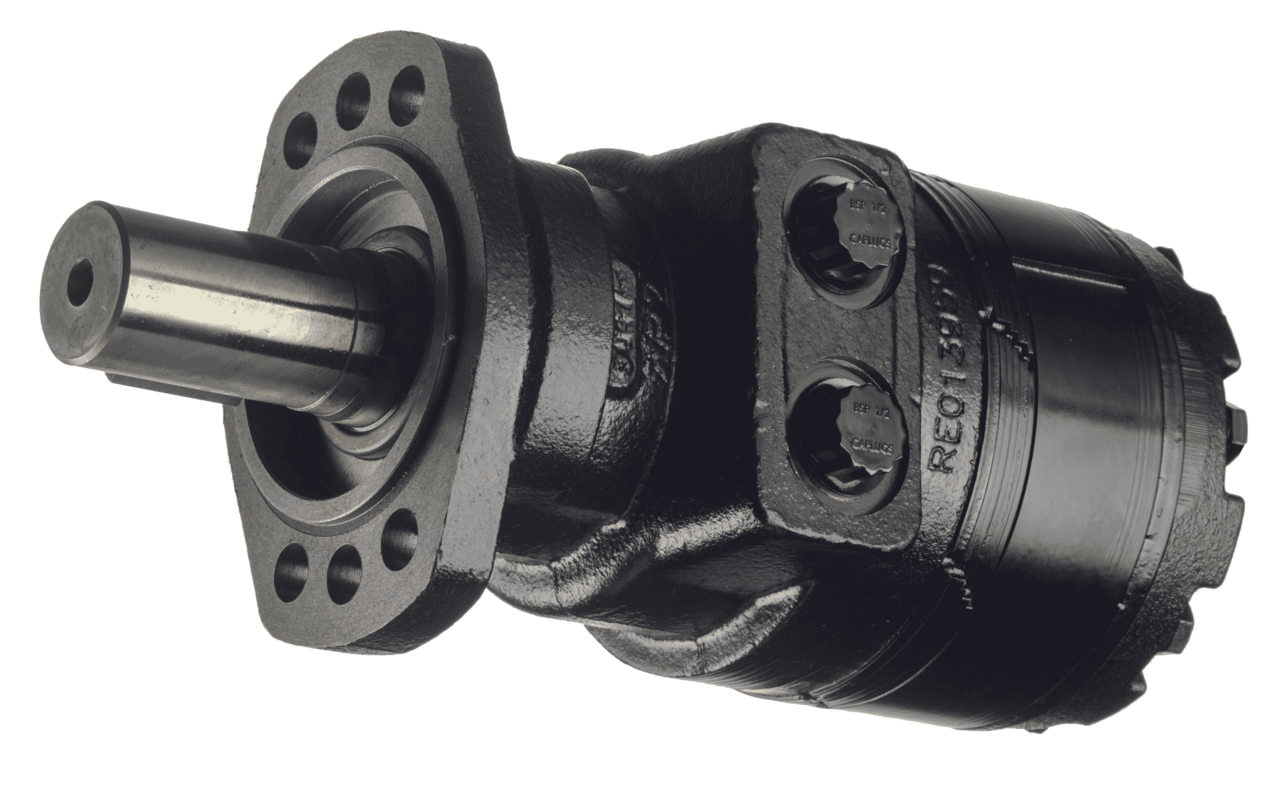

Radial Piston Motors (select models)

Deliver extremely high torque at low speeds, suitable for applications like wheel drives in self-propelled concrete pumps.

System Applications within Putzmeister® Concrete Pumps:

-

Main Pumping Unit

Axial piston pumps drive the powerful hydraulic cylinders that move concrete through the pipeline. -

Agitator Motor

Keeps concrete well mixed in the hopper using high-torque hydraulic motor power. -

Boom System Motors

Control the complex movements of the placing boom—raising, lowering, swinging, and extending. -

Outrigger Motors

Extend and stabilize the machine through hydraulic actuation during setup and operation. -

Water Pump Motors

Drive auxiliary pumps used for system cleaning and maintenance. -

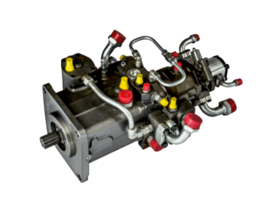

Auxiliary Pumps

Power small hydraulic functions like remote control systems, valve actuation, and pilot pressure supply.

Why It Matters for Concrete Delivery:

-

Delivers the Power Behind Every Pump Stroke

Vital for driving the high-pressure concrete delivery system. -

Precision Placement of Concrete via the Boom

Smooth, accurate boom movement ensures efficiency and safety on the job site. -

Keeps Your Hopper Consistently Mixed

Prevents clogs and ensures quality concrete delivery. -

Supports Fast Setup and Safe Operation

Reliable hydraulic outrigger function and auxiliary systems keep operations moving.

For detailed specifications—including model numbers, flow and pressure ratings, displacement values, torque outputs, and compatibility with specific Putzmeister® concrete pump models—refer to official Putzmeister® technical documentation and parts catalogs.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...