Putzmeister

Putzmeister® Hoppers, Hopper Mixers and Accessories Series

Putzmeister® Hoppers, Hopper Mixers and Accessories Series

Smooth Intake, Continuous Mixing, Reliable Flow

The Hoppers, Hopper Mixers & Accessories Series, engineered for compatibility with Putzmeister® concrete pumps, includes robust hoppers, integrated agitators, and essential support components that ensure efficient material handling before pumping. These parts are designed to promote consistent concrete flow, prevent mix segregation, and provide easy access for maintenance—all vital for maximizing jobsite performance.

🔧 Key Features & Benefits:

-

Optimized Concrete Flow

Hopper design ensures smooth intake from truck mixers and directs concrete toward the pump inlet with minimal resistance. -

Integrated Agitation System

Agitator paddles driven by hydraulic or electric motors keep concrete uniformly mixed, ensuring a pumpable, high-quality mix throughout operations. -

Heavy-Duty Construction

Built from abrasion-resistant steel to withstand concrete wear, dynamic loads, and continuous operation. -

Smart Accessory Integration

Safety grids, level sensors, inspection hatches, and grease points support safe, efficient, and low-maintenance usage. -

Perfect Putzmeister® Fit

Mounts, drive units, and hydraulic valves are compatible with various Putzmeister® models and configurations. -

Designed for the Real World

Features like wear liners, isolators, and quick-access panels make this series ideal for high-cycle jobs in demanding conditions—from Burnaby to beyond.

🧩 Component Overview:

| Component | Purpose & Function |

|---|---|

| Main Hopper | Steel vessel where fresh concrete is received and held before being pumped. |

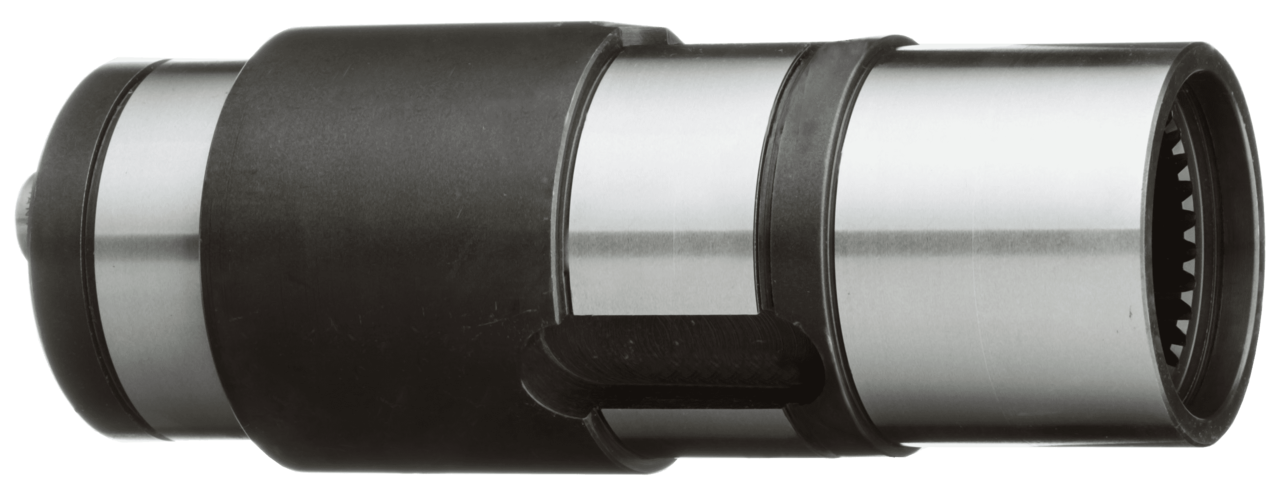

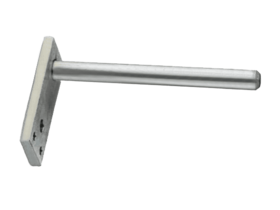

| Agitator Drive Unit | Powers mixer paddles inside the hopper—can be hydraulic or electric. |

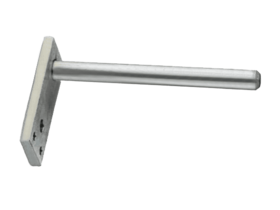

| Agitator Shaft & Paddles | Continuously stirs concrete to prevent settling and segregation. |

| Safety Grid | Prevents oversized debris and increases operator safety. |

| Hydraulic Valve Block | Directs hydraulic flow to agitator motor and gate controls. |

| Inspection Hatch | Quick access for cleaning, visual checks, or part replacement. |

| Level Sensor | Monitors hopper fill level for operator awareness or automation. |

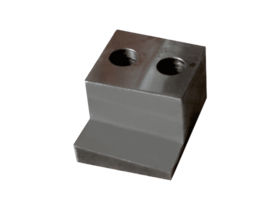

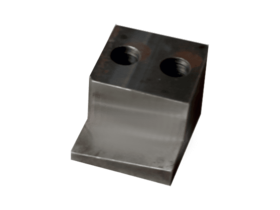

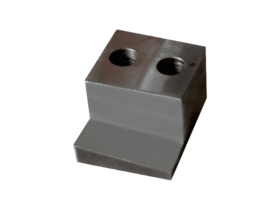

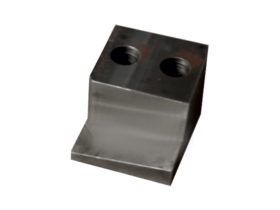

| Wear Plates/Liners | Replaceable inserts protect high-wear zones inside the hopper. |

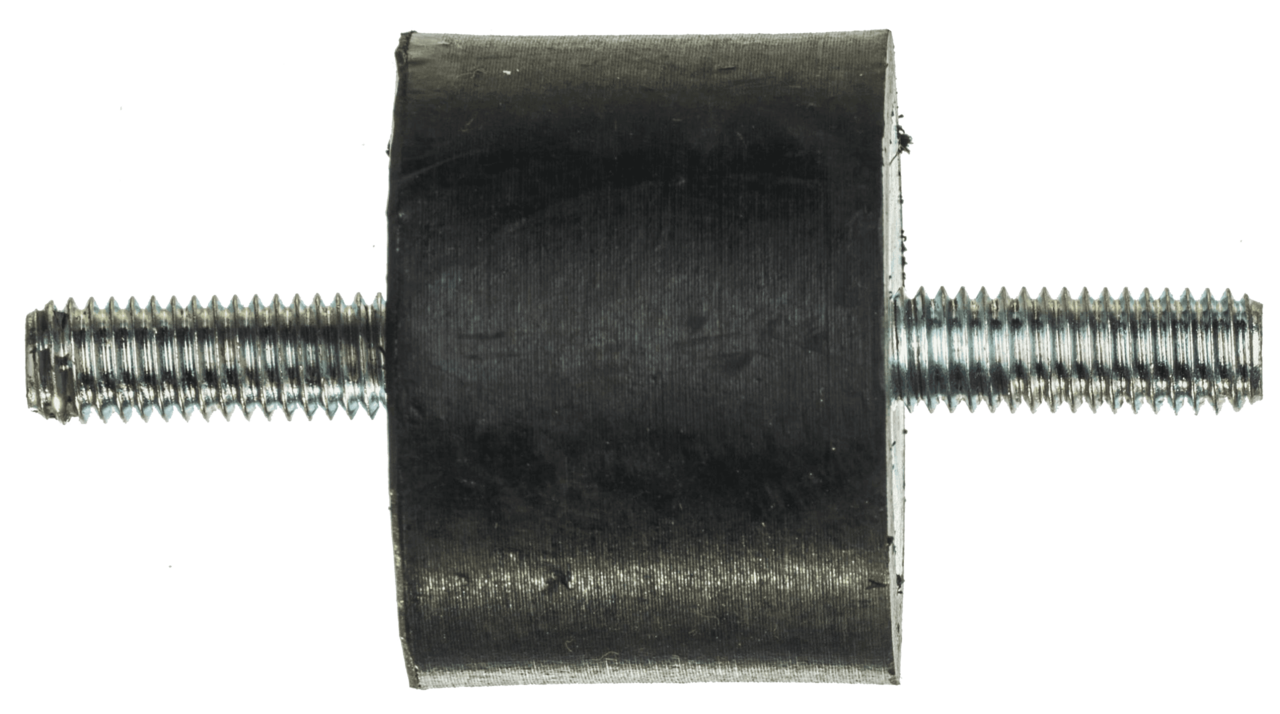

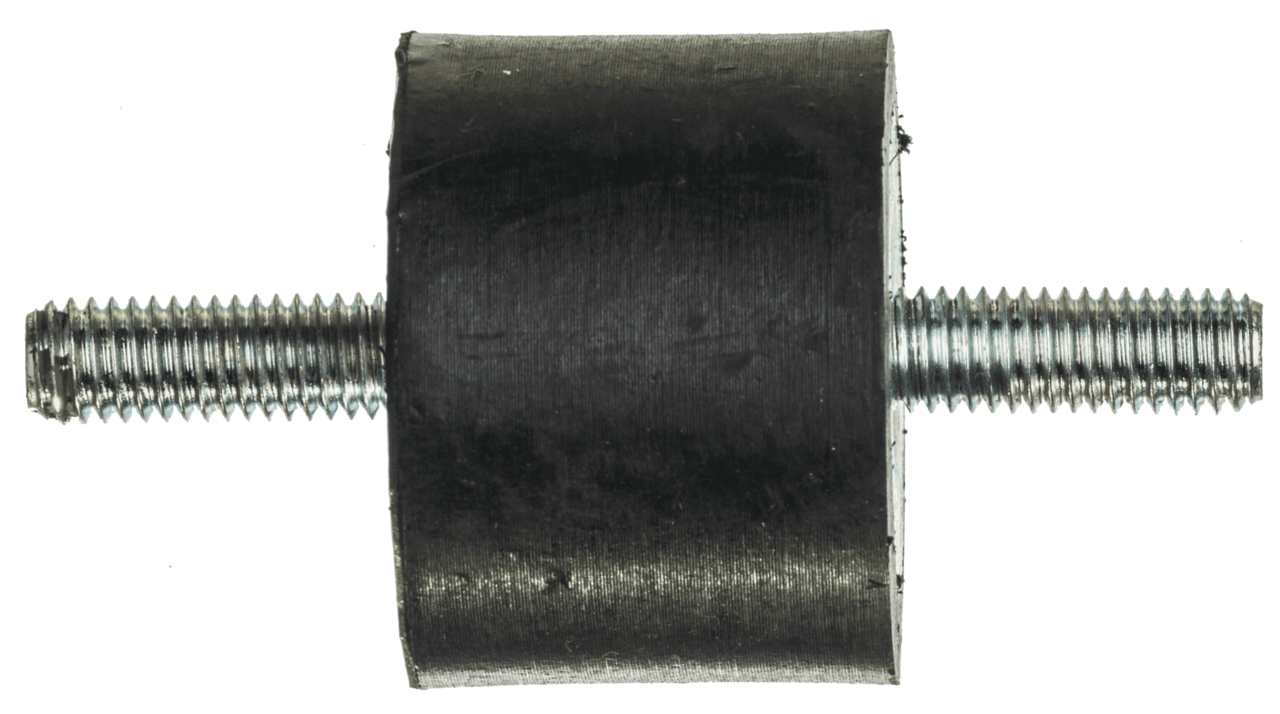

| Rubber Vibration Isolators | Absorb mechanical stress and reduce vibration to extend component life. |

| Grease Fittings | Lubrication points for key moving parts. |

| Discharge Gate Actuator | Opens/closes bottom gate to control flow into the pump cylinders. |

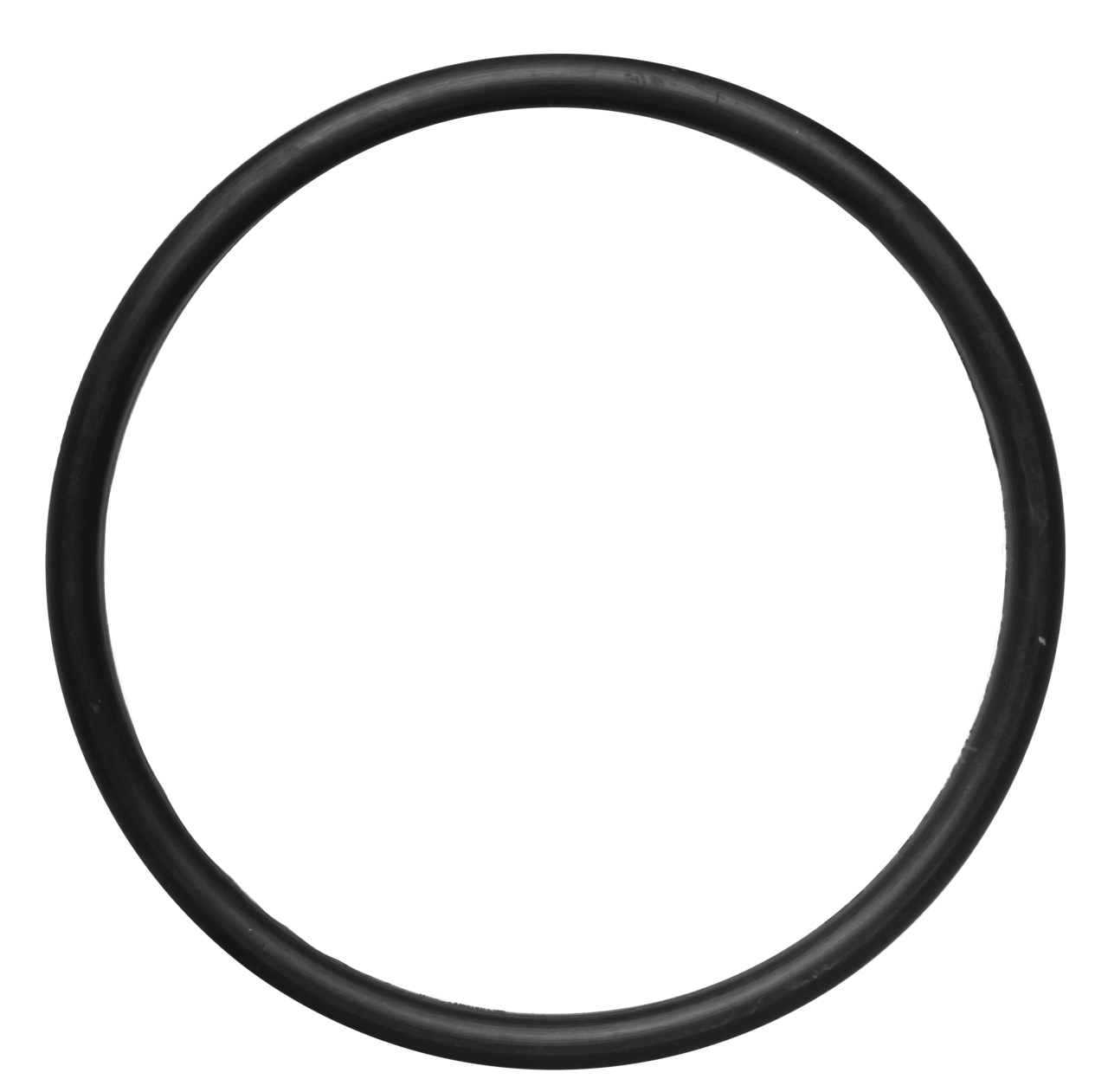

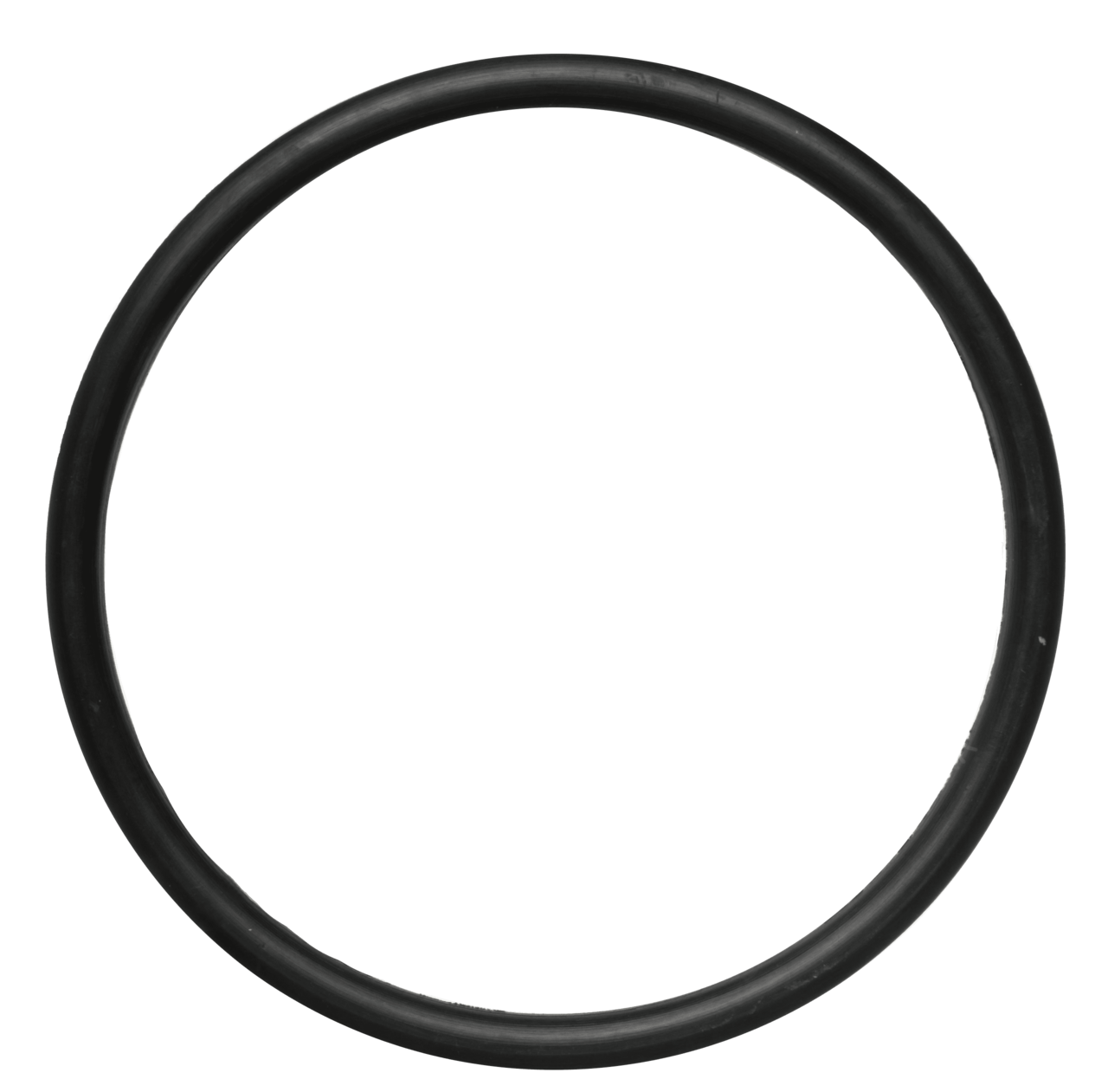

| Sealing Elements | Prevent leaks at critical joints or access panels. |

| Manual Control Levers | Allow direct operator input for gates or auxiliary functions. |

🚜 Where It Fits in the Pumping System:

-

Concrete Entry Point

The hopper receives fresh concrete from a truck or chute and directs it toward the pumping mechanism. -

Agitation Zone

Internal mixer paddles ensure consistent texture and pumpability. -

Final Feed to Cylinders

Hopper base aligns with suction openings, feeding concrete directly into the pumping cylinders.

🎯 Why It Matters for Your Operation:

-

✅ Consistent Material Flow – Minimize surge, blockage, or air pockets.

-

✅ Mix Quality Maintenance – Keep aggregates and slurry evenly blended.

-

✅ Operator Safety – Grids, sensors, and covers help protect your crew.

-

✅ Time-Saving Design – Streamlined cleaning and easy part access reduce downtime.

📏 Spec & Sizing Note:

When selecting components, ensure compatibility by checking:

-

Pump model and frame series

-

Drive motor type (hydraulic/electric)

-

Hopper capacity and inlet size

-

Control systems (manual vs. automated)

-

Wear liner style and mounting format

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...