Putzmeister

Putzmeister® Flap Elbows & Accessories Series

Putzmeister® Flap Elbows & Accessories Series

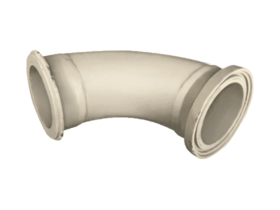

The Flap Elbows & Accessories Series includes heavy-duty elbow sections with integrated flap valves designed to provide precise control over concrete flow within the delivery line. Positioned at end or intermediate points in the pipeline, these components prevent material fallback, reduce waste, and streamline cleaning and maintenance operations on the jobsite.

🧱 Key Features & Advantages:

-

Controlled Discharge

The integrated flap valve enables precise regulation of concrete flow—ideal for starting, stopping, or redirecting discharge on demand. -

Backflow Prevention

Acts as a one-way check valve, preventing material fallback in the delivery pipe—critical for work on inclined sections. -

Streamlined Cleaning

The flap design allows easier access to the pipeline interior, simplifying the removal of concrete build-up or blockages. -

Rugged, Wear-Resistant Construction

Fabricated from high-strength steel to resist abrasion and high internal pressures from dense concrete flow. -

Fast, Secure Installation

Compatible with heavy-duty clamp couplings like the ZX-W 6.0/150 HD, ensuring secure, leak-proof joints. -

Manual or Hydraulic Operation

Can be operated with simple handles or upgraded with hydraulic actuation for faster, safer control. -

Exact Fit for Putzmeister® Systems

Seamless integration with standard DN 150 delivery lines and accessories.

🧩 Component Breakdown:

| Component | Description & Use |

|---|---|

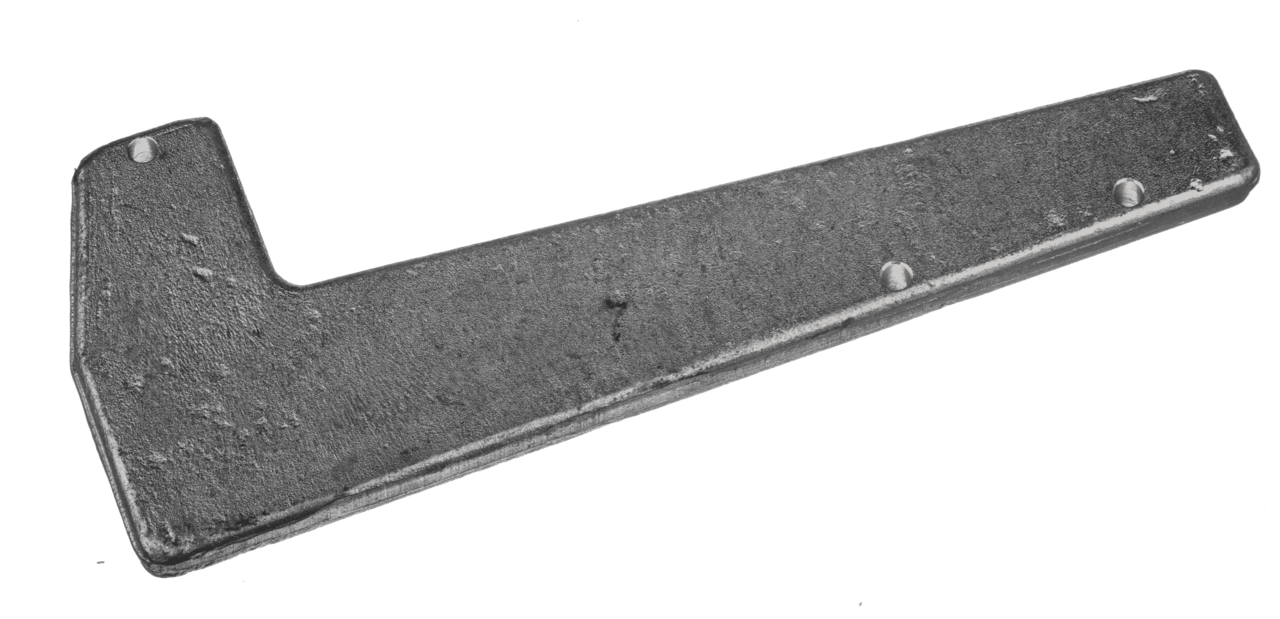

| Flap Elbow Housing | Elbow pipe section with built-in pivot for flap valve—available in different bend angles. |

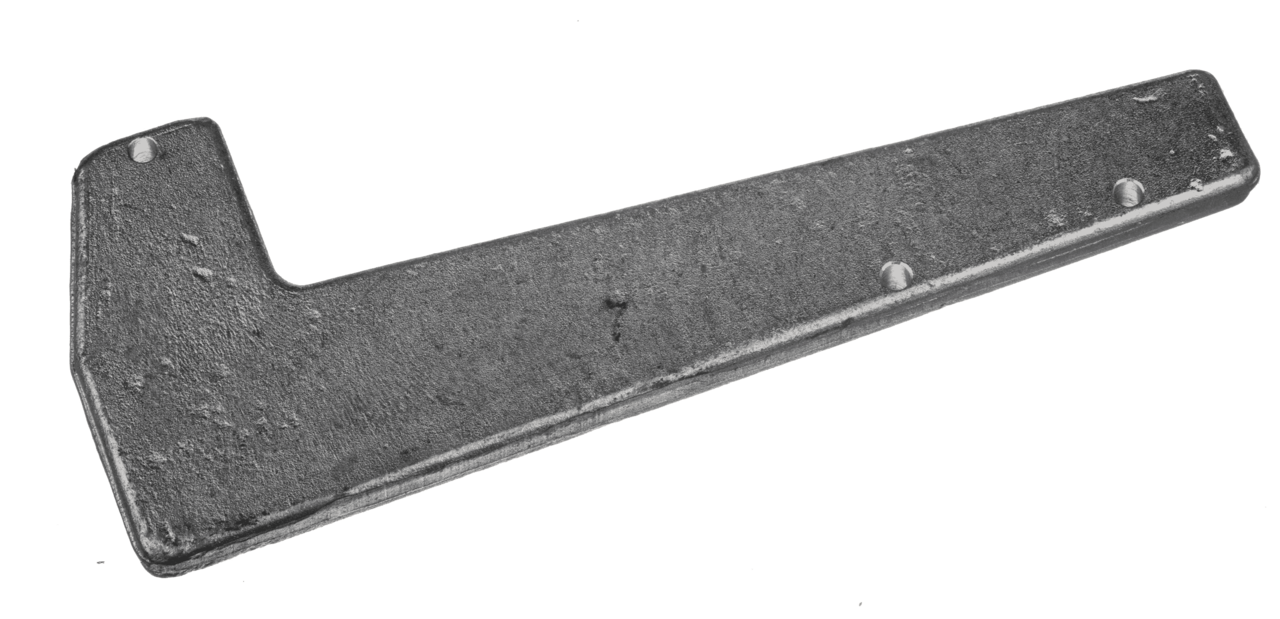

| Flap Valve Plate | Internal gate that swings open/closed to control concrete discharge. |

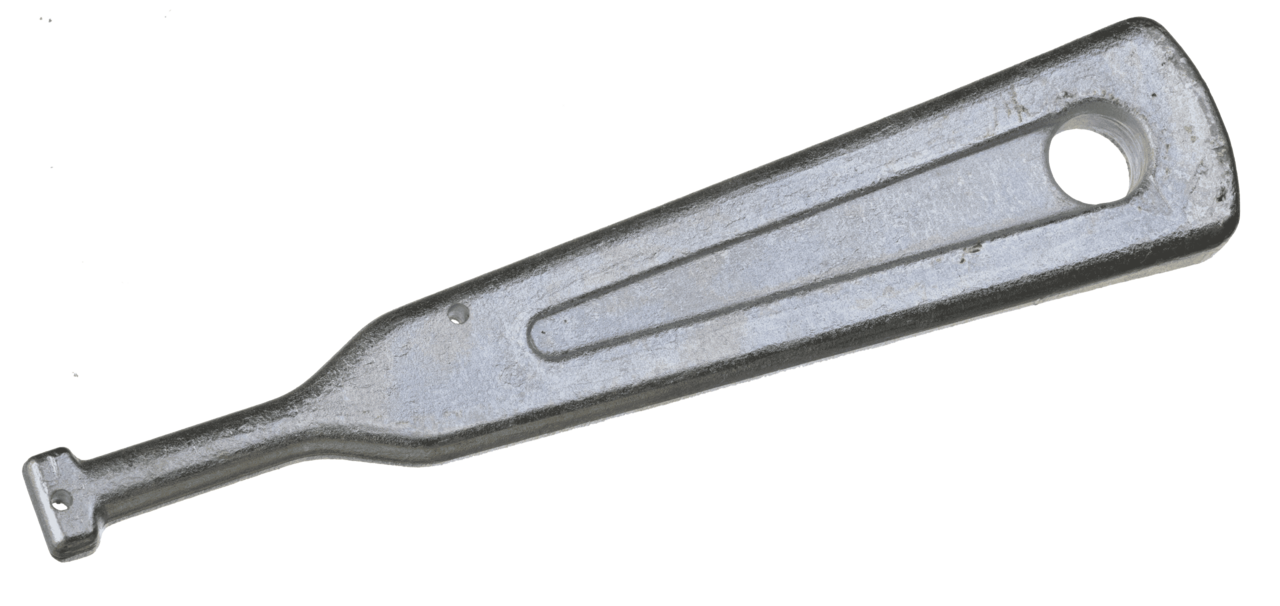

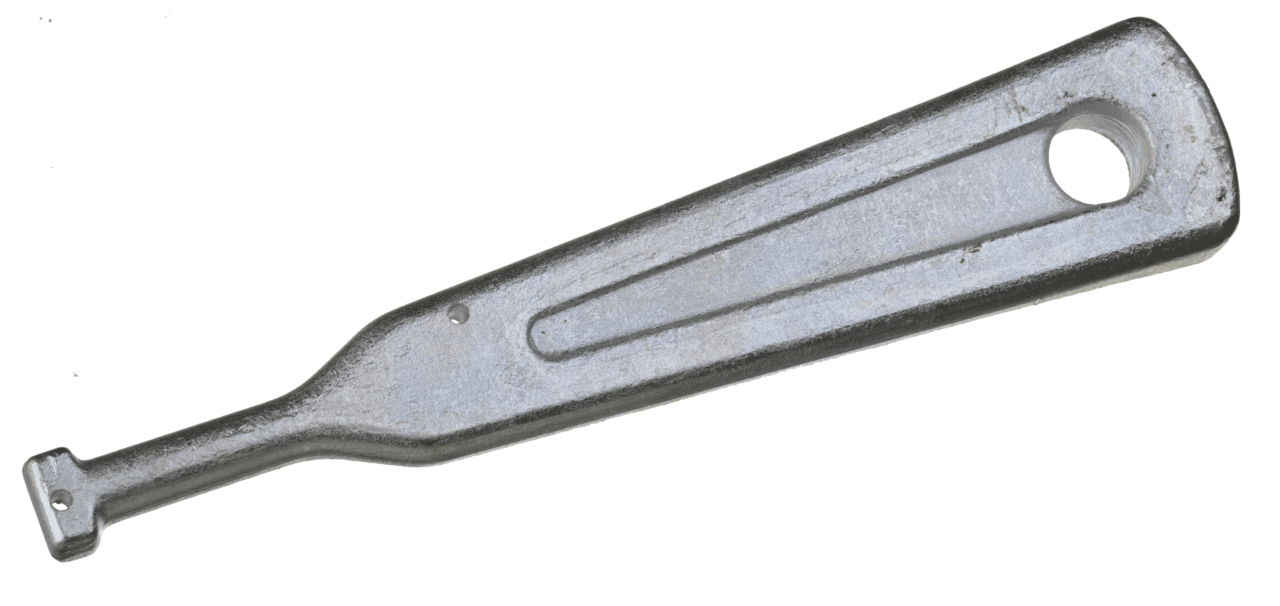

| Actuation Mechanisms | Manual levers, pins, or hydraulic cylinders that move the flap into position. |

| Clamp Coupling ZX-W 6.0/150 HD | Heavy-duty clamp for DN 150 pipe systems—rated up to 6.0 MPa for high-pressure connections. |

| Sealing O-Rings & Gaskets | Prevent leaks around flap axis and coupling points. |

| Fasteners & Alignment Pins | Hold internal flap components securely in place under load. |

🏗️ Installation & Application Points:

-

End of Delivery Line

Final control point for placing concrete precisely where needed—especially helpful during finishing or slab work. -

Intermediate Line Sections

Optional discharge locations for multi-zone pours or for redirecting flow on multi-level projects. -

Cleaning Access Points

Quickly open the flap for water flushing or manual blockage removal after pumping.

🚨 Operational Benefits:

-

Enhanced Jobsite Safety:

Prevent uncontrolled surges or concrete dumping. -

Concrete Placement Accuracy:

Better control = less mess, more precision. -

Downtime Reduction:

Flap elbows make cleaning faster, cutting down on total maintenance time. -

Wear & Waste Minimization:

Stop concrete flow instantly—no dripping or overpouring.

📏 Technical Note:

For complete compatibility and optimal performance, always verify specifications like:

-

Pipe diameter: DN 150

-

Coupling type: ZX-W series

-

Pressure rating: up to 6.0 MPa

-

Material: Wear-resistant cast or steel elbow, rubber-seated or metal flap valve

-

Actuation: Manual or hydraulic

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...