Putzmeister

Putzmeister® Filters Series

Putzmeister® Filters Series

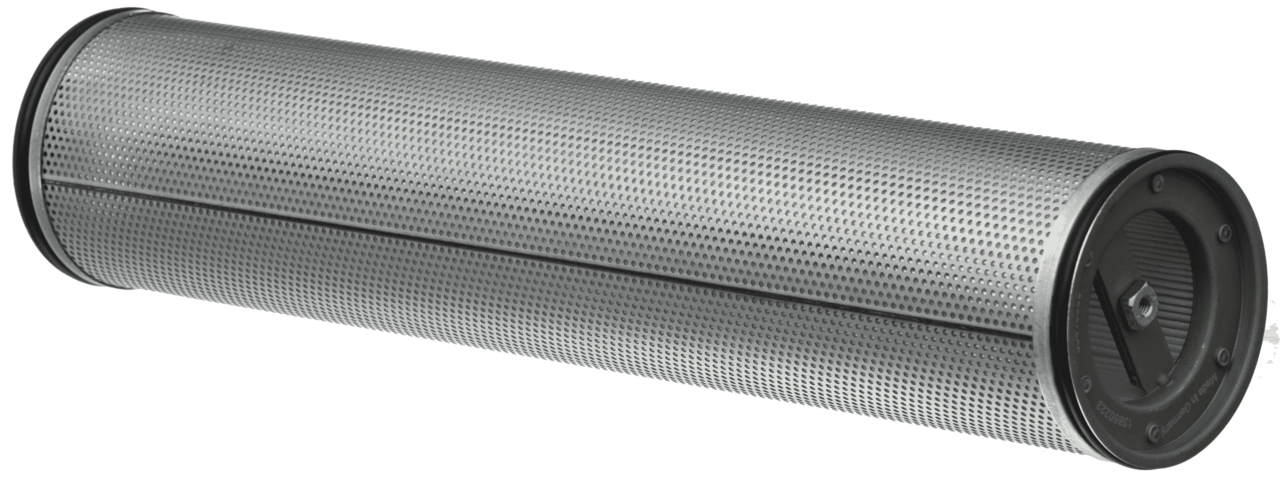

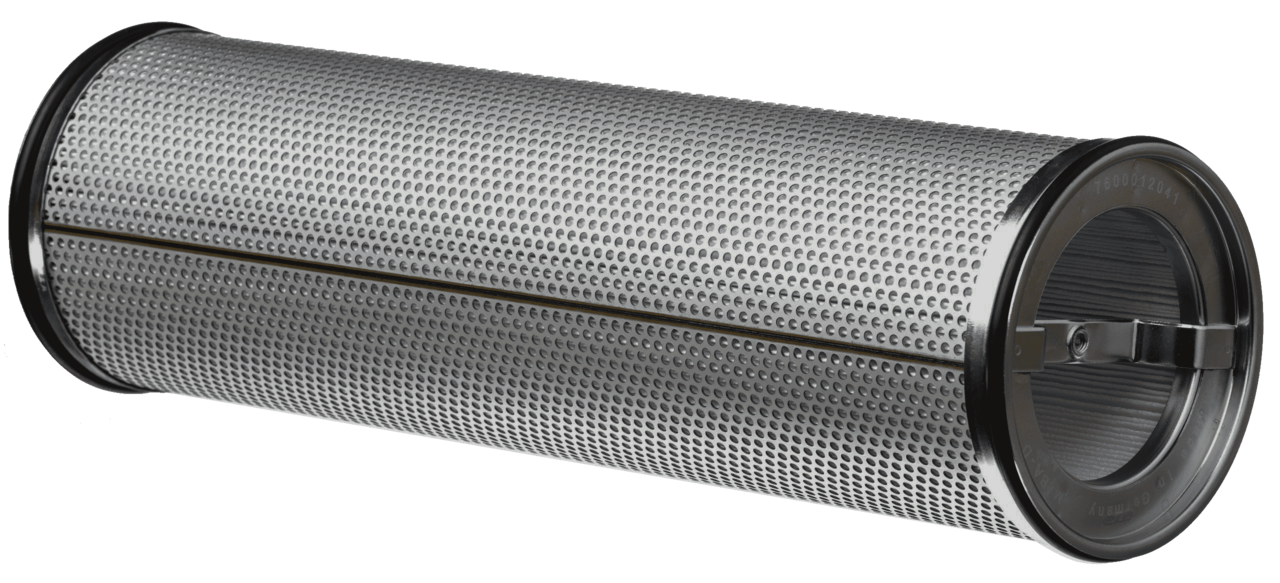

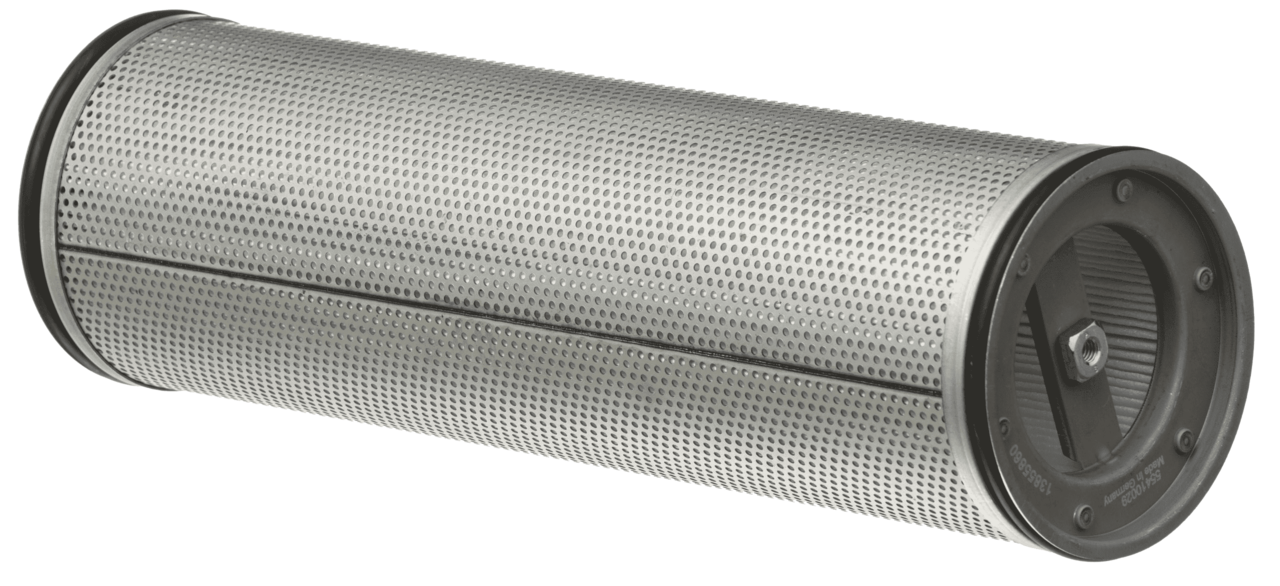

Filtration Solutions for Concrete Pump Protection and Performance

The Filters Series, compatible with Putzmeister® concrete pumps, includes high-efficiency hydraulic, air, fuel, and water filters engineered to maintain fluid cleanliness and ensure optimal performance of critical systems. These filtration components are essential for preventing contamination-related failures and extending the life of key hydraulic and engine components—especially in heavy-duty applications like concrete pumping

🛡️ Key Features & Advantages:

-

Superior Contaminant Removal

Effectively filters out dirt, metal shavings, and other harmful particles from hydraulic fluid, air, fuel, and water systems. -

Protection for Hydraulic and Engine Components

Safeguards pumps, valves, cylinders, injectors, and other sensitive parts from wear and failure. -

Extended Equipment Life

Maintains system health and prolongs the life of high-value components, reducing total cost of ownership. -

Optimized Pump Performance

Clean fluids ensure smooth, efficient hydraulic operation—supporting consistent concrete delivery and pump responsiveness. -

Wide Range of Media & Ratings

Available in various micron ratings and materials (synthetic fiber, wire mesh, cellulose, etc.) tailored to system requirements. -

Durable Construction

Engineered to handle the pressure, temperature, and flow demands of concrete pump applications. -

Quick Replacement Design

Many filters are spin-on or cartridge-style for fast, easy change-outs—minimizing downtime during maintenance.

🧩 Filter Types & Applications:

| Filter Type | Function |

|---|---|

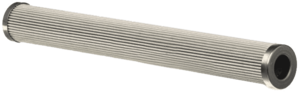

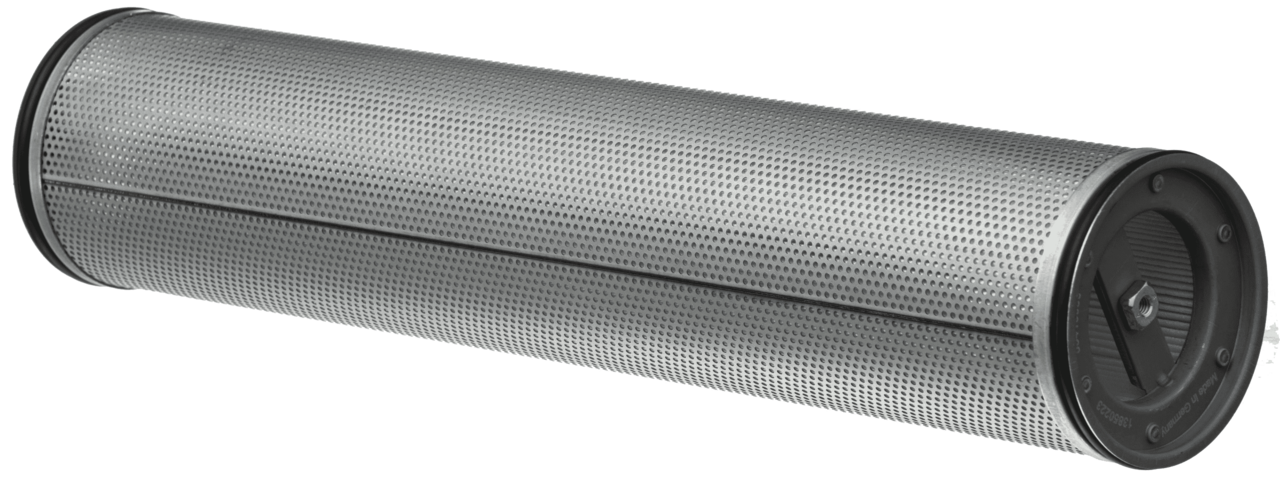

| Hydraulic Filters (Spin-on / In-line) | Protect hydraulic circuits from contamination—critical for pumps, cylinders, and valves. |

| Air Filters | Clean air intake for engines or hydraulic tank breathers to prevent dust ingress. |

| Fuel Filters | Ensure clean fuel delivery to the engine for optimal combustion and reduced injector wear. |

| Oil Filters | Clean engine oil to minimize internal wear and extend oil change intervals. |

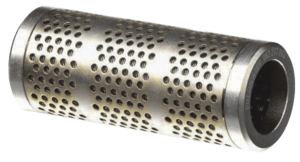

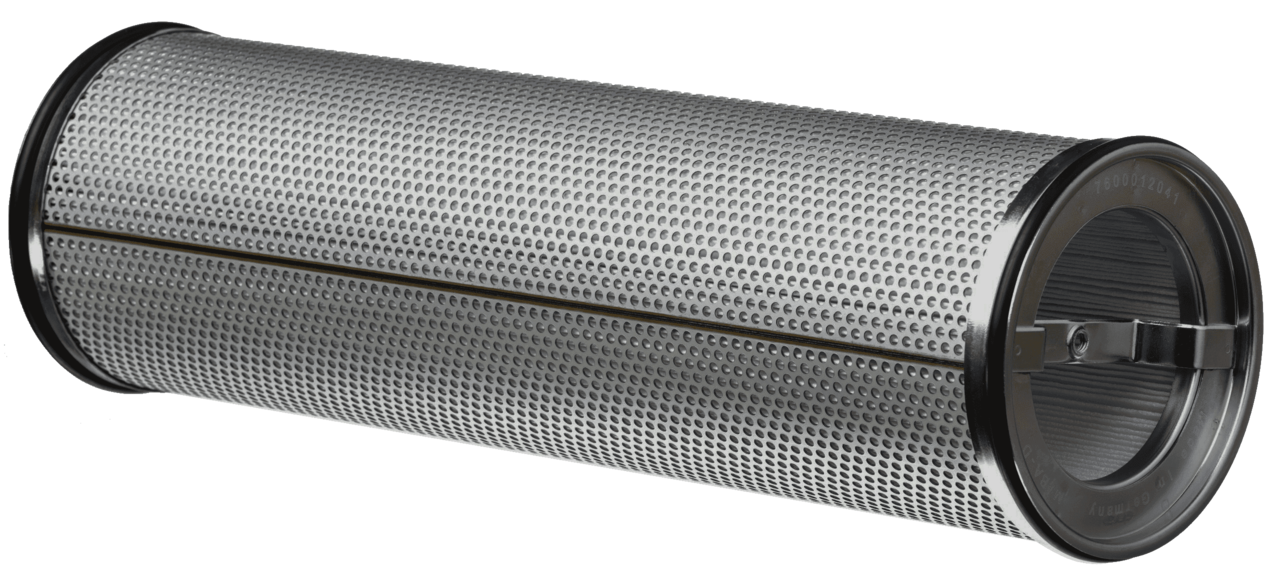

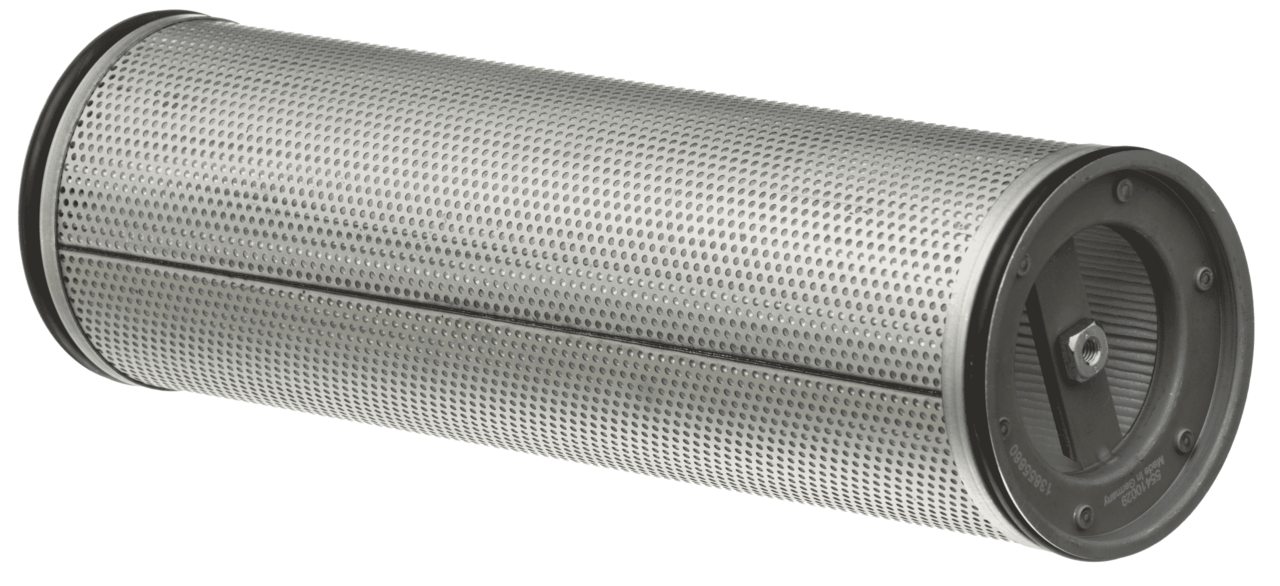

| Suction Strainers | Positioned inside hydraulic reservoirs to filter large debris before fluid reaches the pump. |

| Water Filters | Prevent clogging in spray or cleaning systems by capturing particles in wash water circuits. |

⚙️ Commonly Compatible Components:

-

MAHLE® Spin-On Hydraulic Filters

Direct-fit for many Putzmeister® hydraulic systems—trusted for high dirt-holding capacity. -

Breather & Suction Elements

Used in hydraulic tanks and fluid reservoirs to prevent airborne or particulate contamination. -

Filter Housings & Assemblies

Complete units available for high-pressure and return-line filtration—built to Putzmeister® specifications.

📈 Benefits for Concrete Pump Operations:

-

Prevents hydraulic system breakdowns due to contamination.

-

Reduces engine wear and fuel system inefficiencies.

-

Enhances equipment reliability and reduces maintenance frequency.

-

Supports consistent and powerful concrete flow without pressure loss or lag.

📘 Selection & Support:

For proper part selection, consult your pump’s service manual or the Putzmeister® parts catalog. Match based on:

-

Micron rating

-

Thread type or housing dimensions

-

Flow rate and pressure compatibility

-

Application system (engine, hydraulic, fuel, water)

Need help finding the right replacement filter? Our team in Burnaby is ready to help you source high-quality compatible options that meet your performance needs and budget.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...