Simem

MSO Series Twin-Shaft Mixers

MSO Series Twin-Shaft Mixers

Maintain the efficiency and longevity of your Simem concrete mixers with our extensive inventory of genuine spare parts. Designed to meet the exact specifications of Simem equipment, these parts ensure optimal performance and durability.

MSO Series Twin-Shaft Mixers

The MSO series is renowned for its robust design and high-performance capabilities. We offer a comprehensive range of spare parts for various MSO models, including:

-

Mixing Arms and Paddles: Bolted onto two primary mixing shafts, these components are designed for different configurations to suit specific mixing requirements.

-

Wear Liners: Fully lined with high-resistance tiles to protect the mixing tank from abrasion, extending the mixer's lifespan.

-

Gearbox Components: Equipped with high-efficiency planetary gearboxes boasting up to 94% mechanical efficiency, complete with integrated oil cooling systems for optimal performance.

-

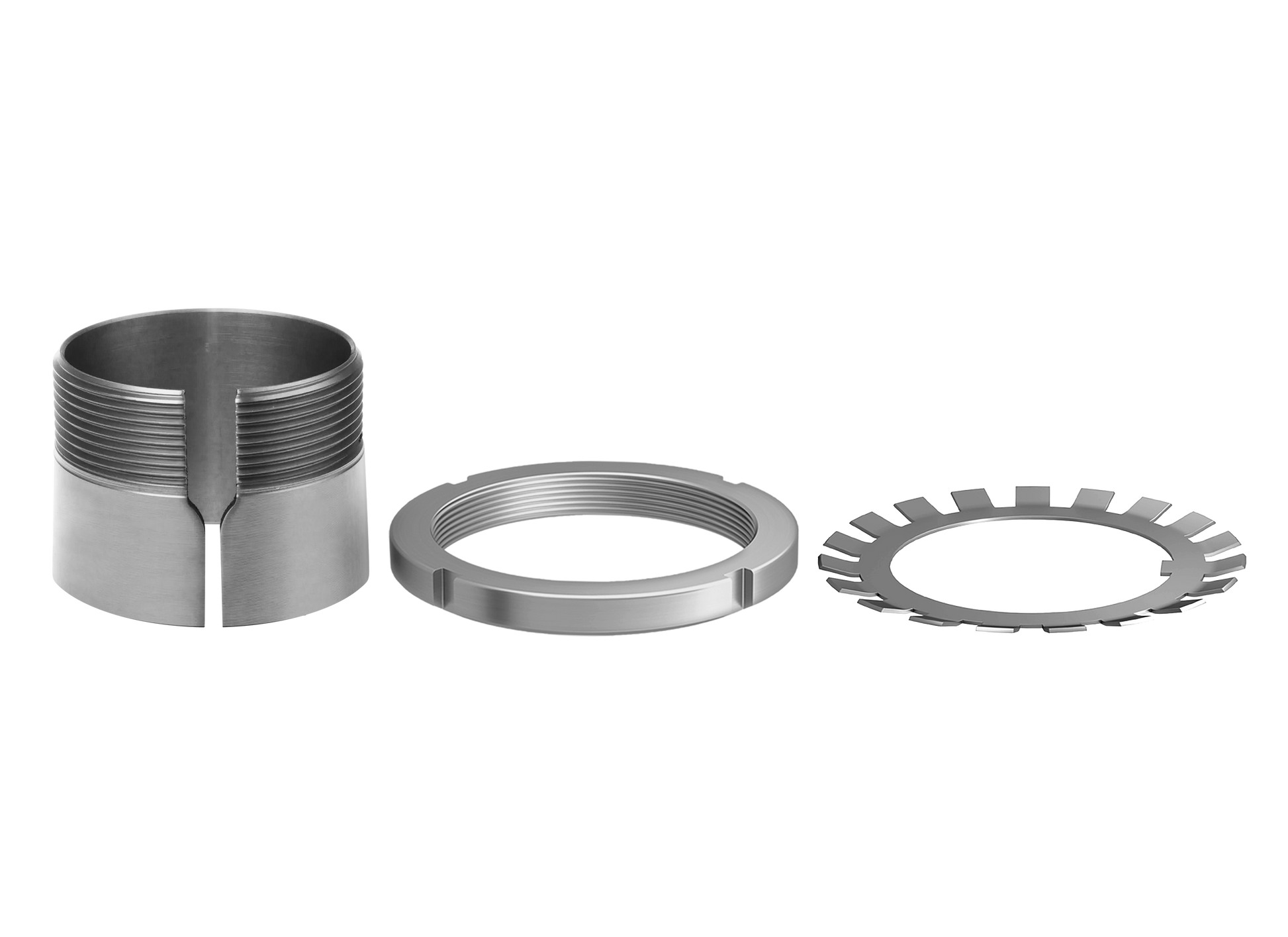

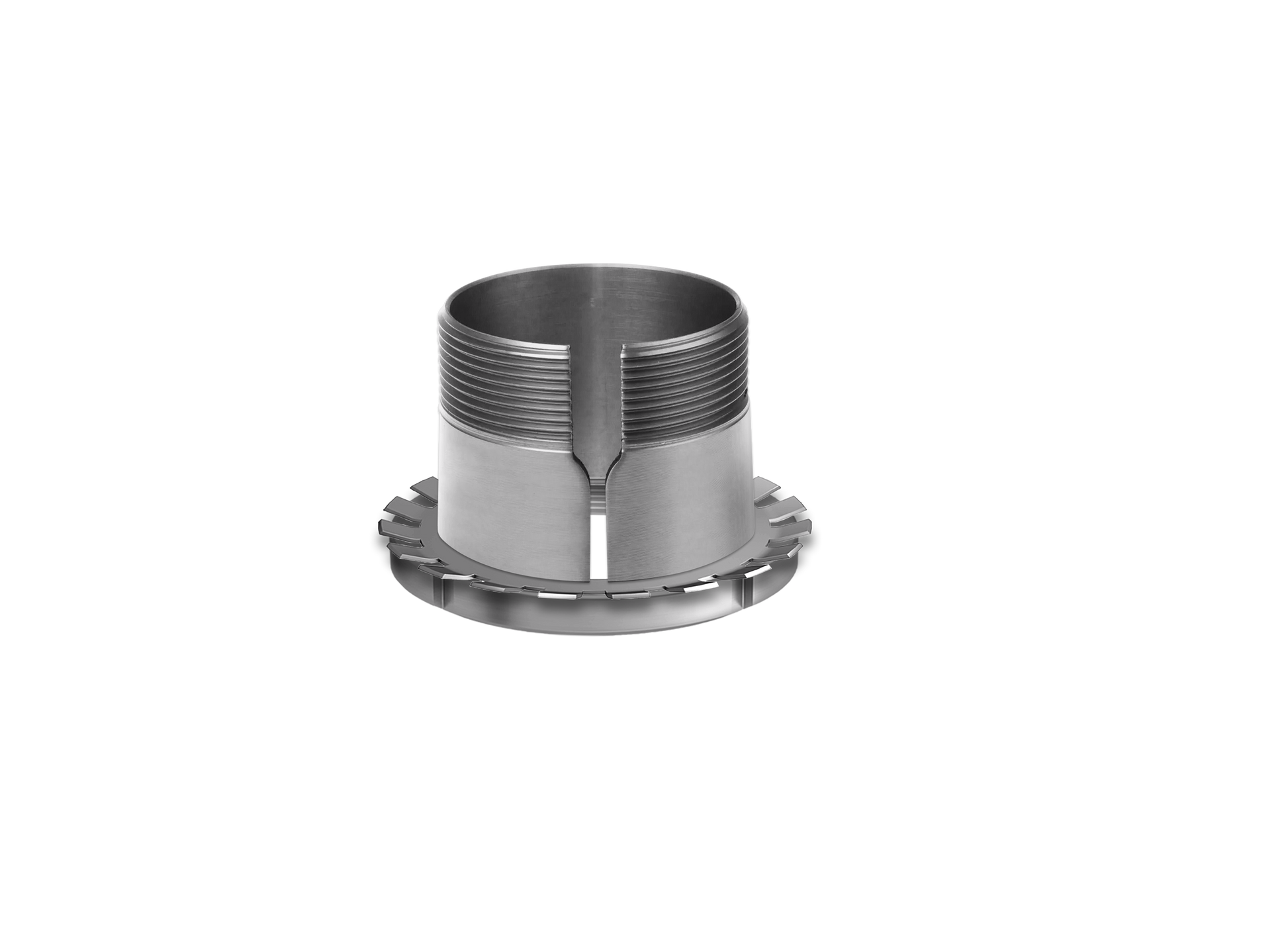

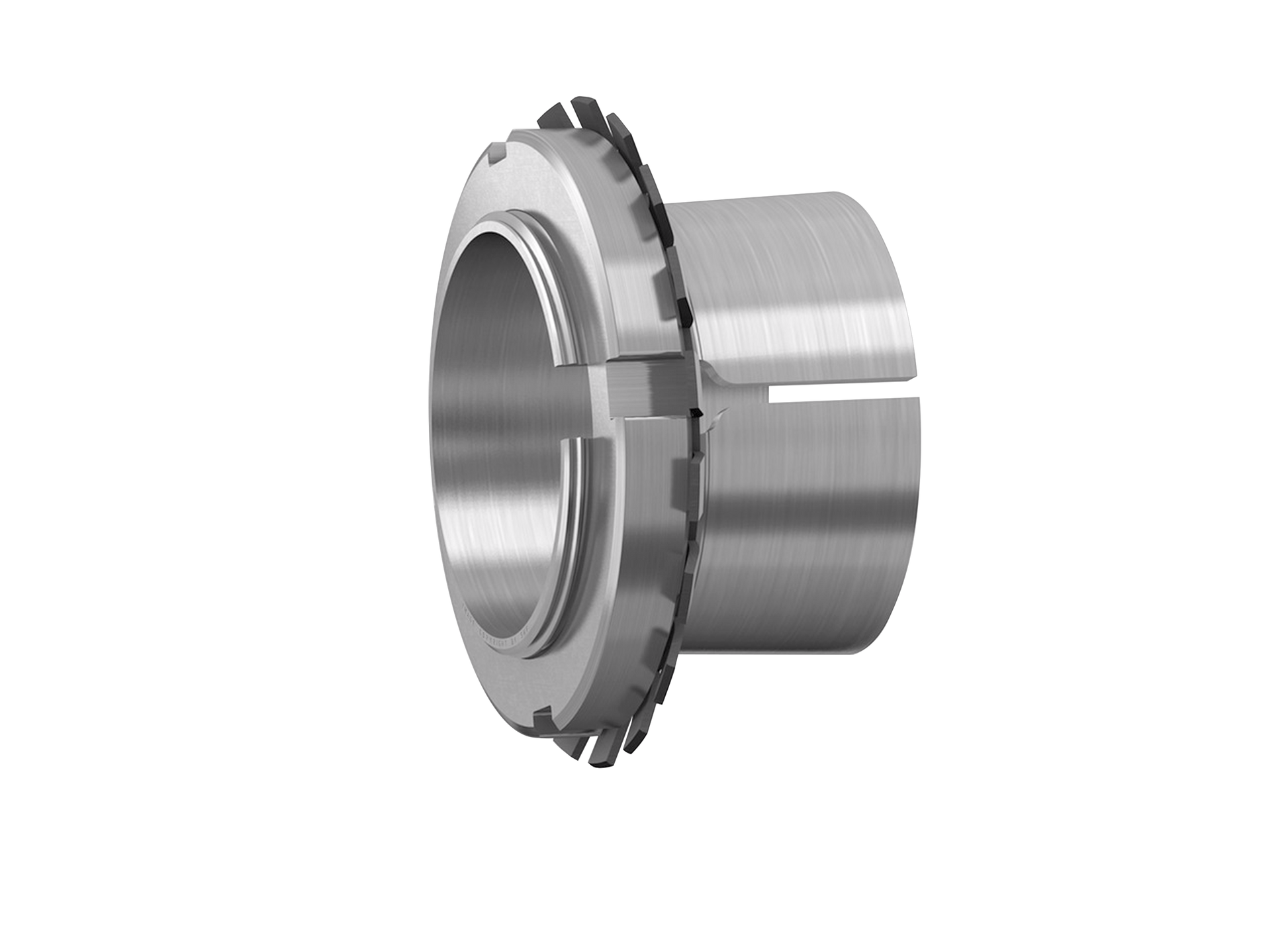

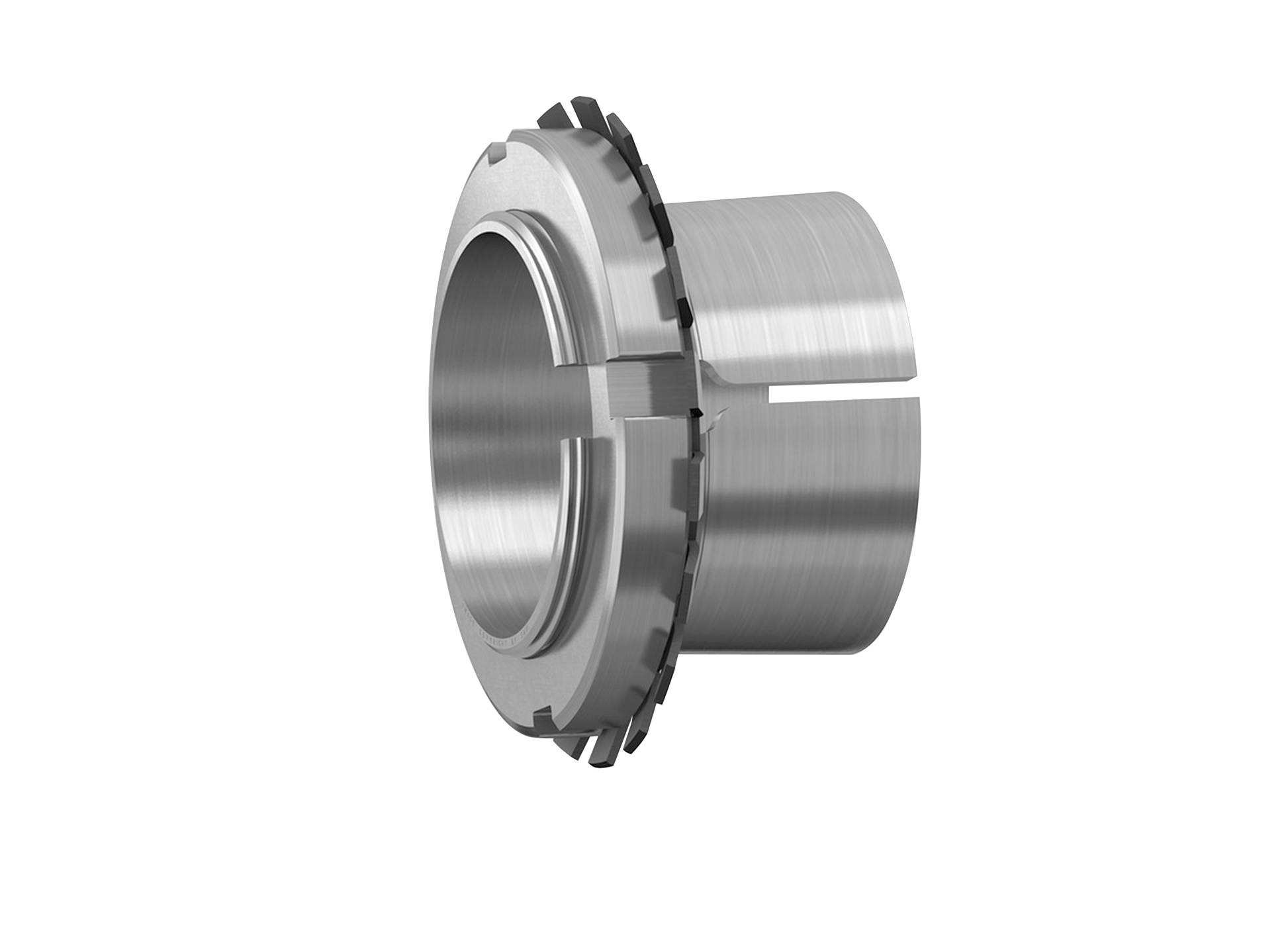

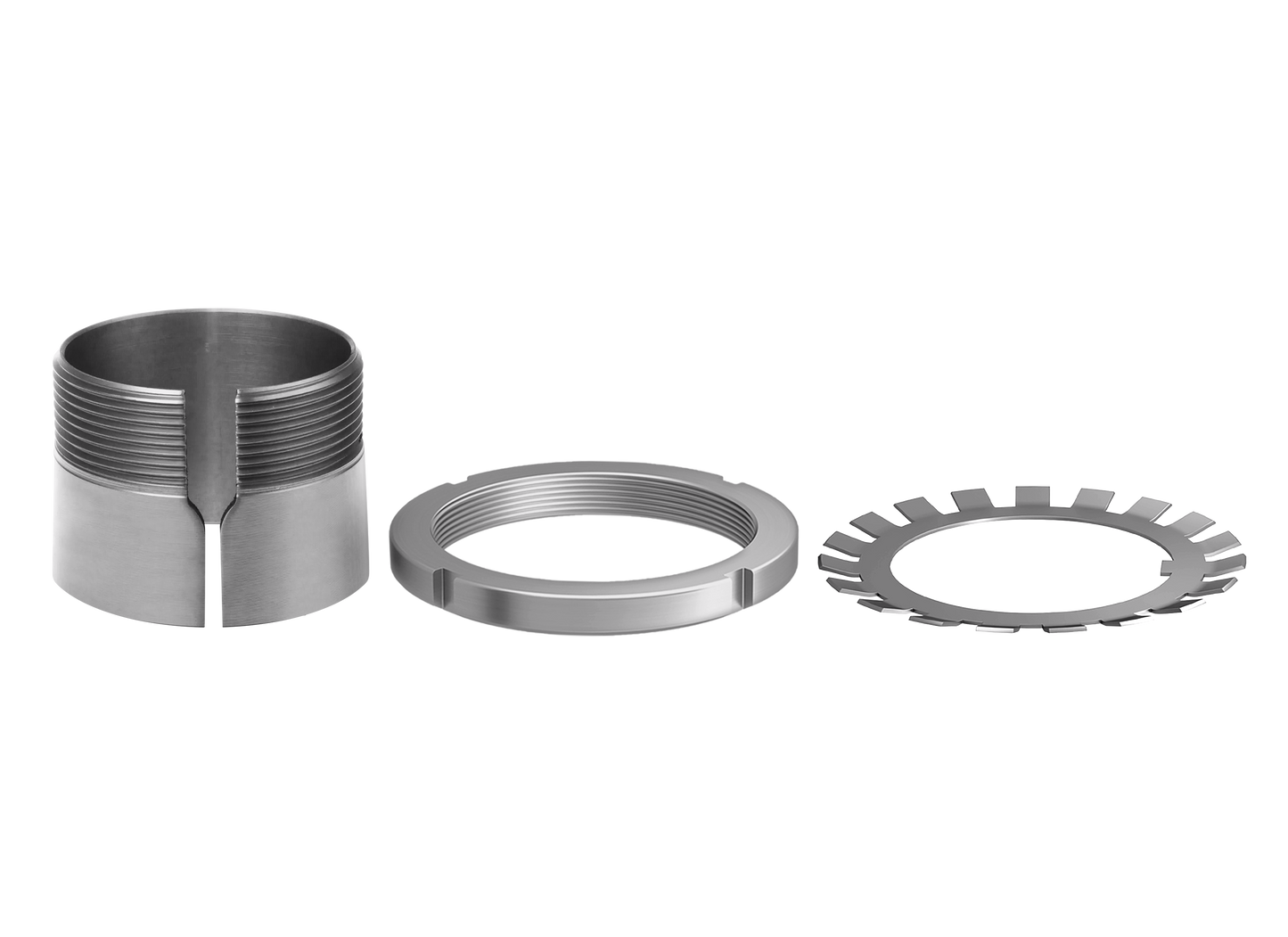

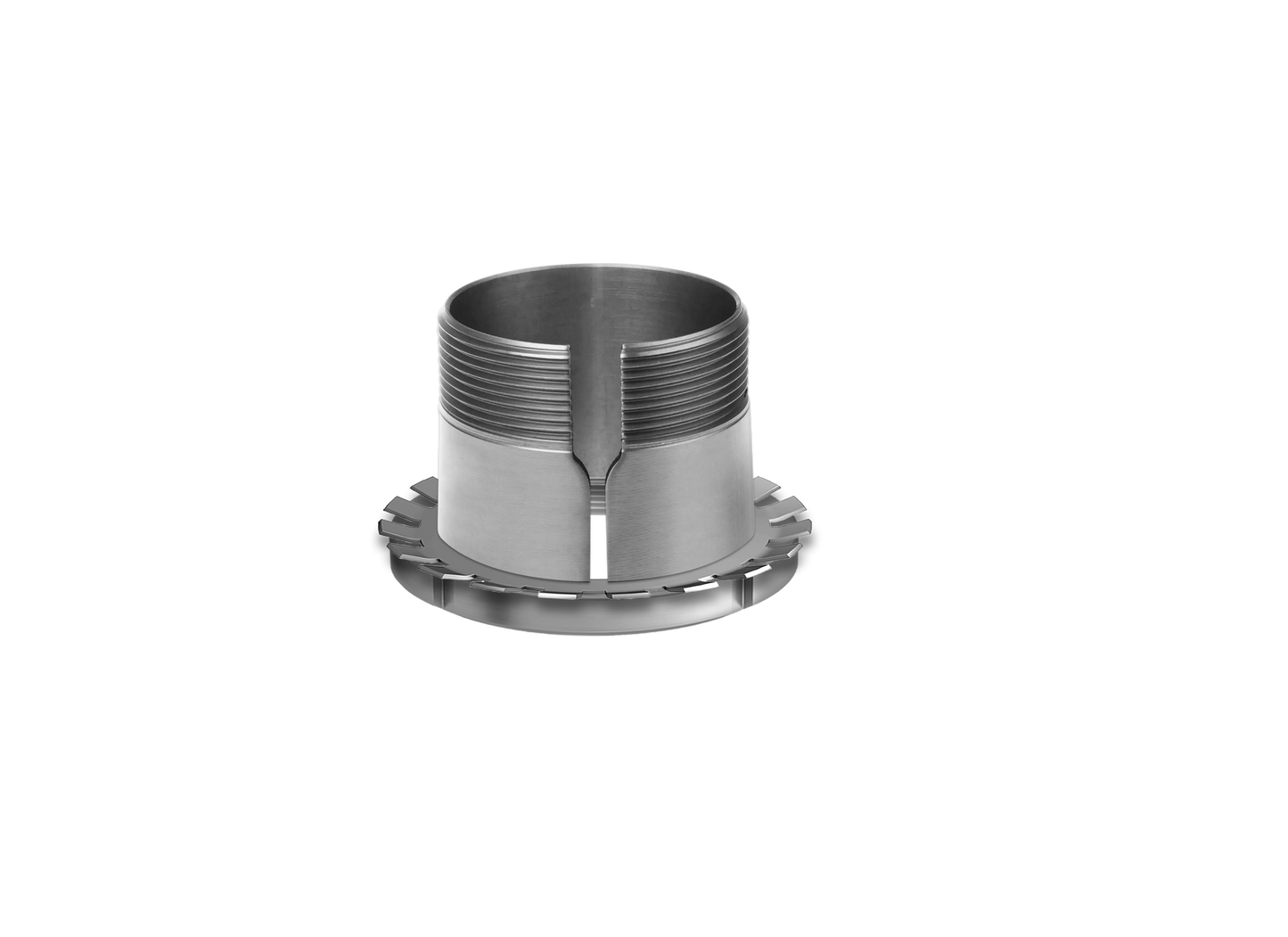

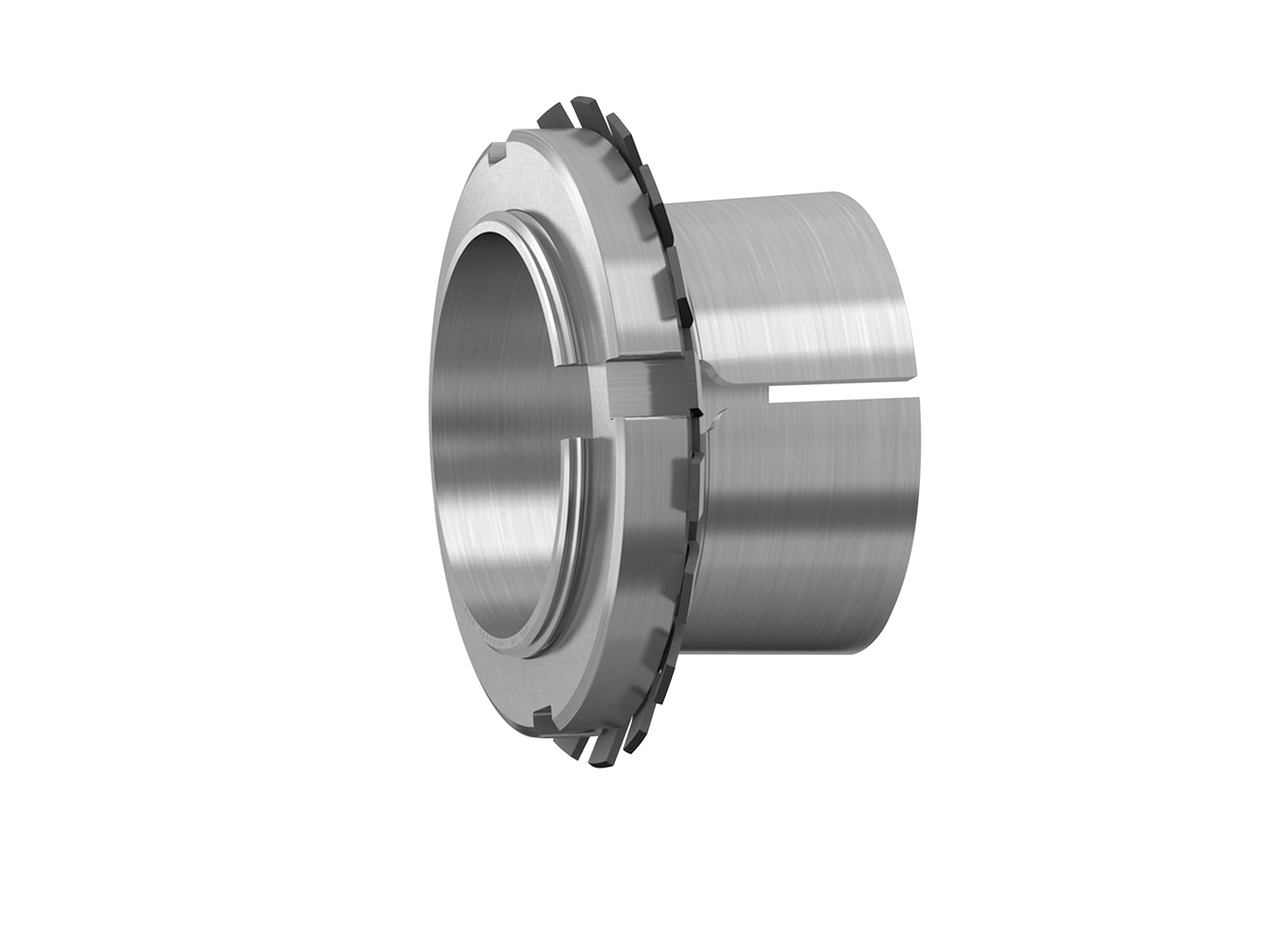

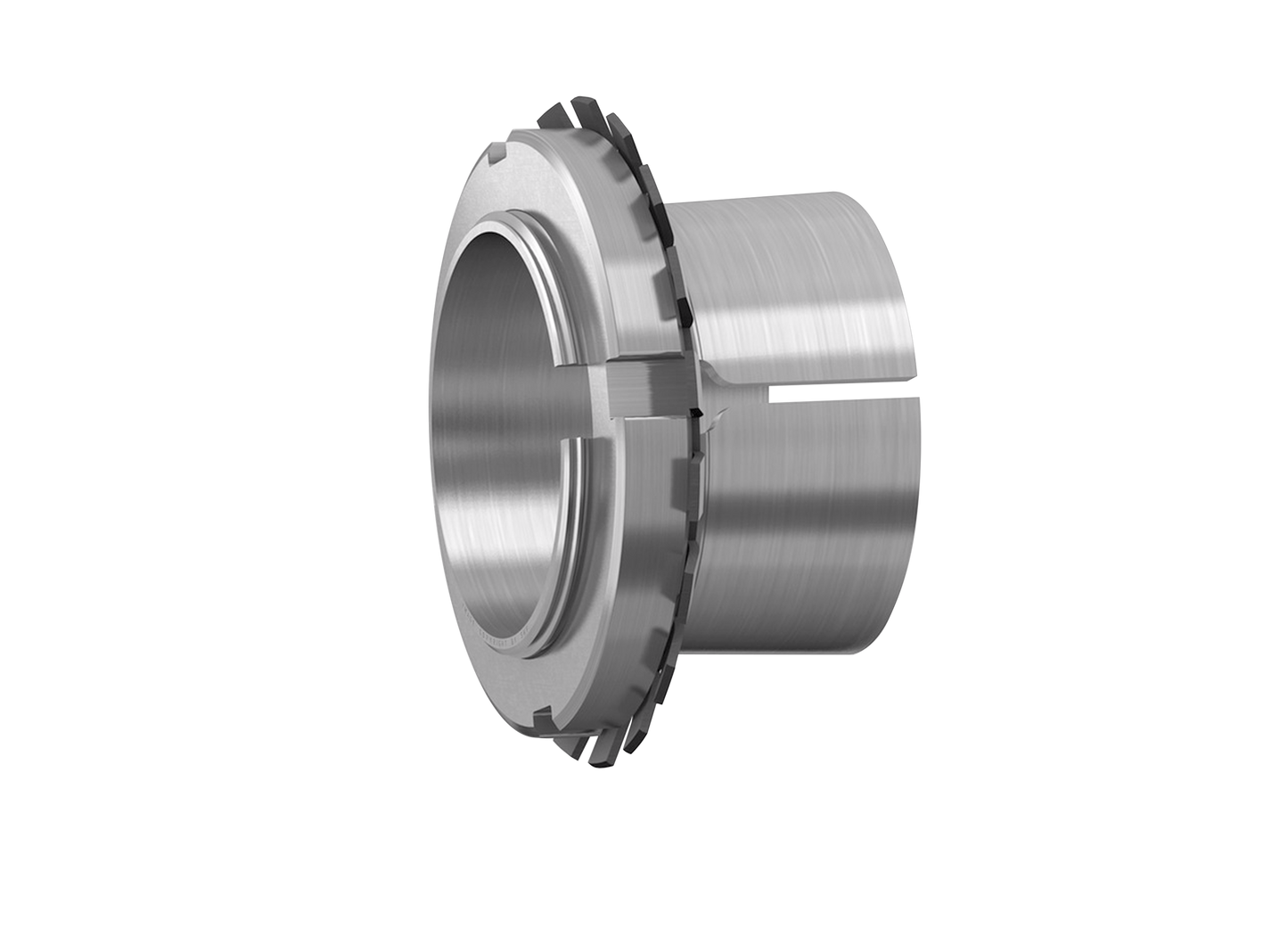

Seals and Greasing Systems: Featuring four special labyrinth mixer shaft seals, continuously lubricated by an electric grease pump with sensors to ensure proper functioning.

For specific models like the MSO 1250, MSO 1500, MSO 2000, MSO 2500, MSO 3000, MSO 3700, MSO 4500, and MSO 6000, we stock all essential wear parts to keep your equipment running smoothly.

RHYNO Series Twin-Shaft Mixers

The RHYNO series represents the next generation of Simem twin-shaft mixers, known for their robust design and innovative features:

-

Mixing Arms and Paddles: Bolted to twin horizontal shafts, allowing for various paddle positions to accommodate diverse mix designs and facilitate easy adjustments.

-

Wear Liners: Lined with stud-mounted high wear-resistant liners to protect against abrasion and extend service life.

-

DYNA-FLOW Mixing System: An innovative arms-paddle mixing system optimized through fluid-dynamic simulation to improve mix results, reduce mixing time, and minimize wear.

Xentrix Series Planetary Mixers

The Xentrix series is distinguished by its exclusive design and efficient mixing action:

-

Mixing Arms and Paddles: Off-center positioning of the main mixing arms allows for central charging of cement, water, and additives, enhancing mixing efficiency. Paddles are made of cast iron or a combination of cast iron core lined with wear-resistant rubber to optimize material flow.

-

Wear Liners: The mixing tank is lined with interchangeable wear liners designed for optimal resistance to abrasion.

-

Water Distribution System: Features an innovative 360° umbrella water distribution system that enhances mix consistency and efficiency.

Additional Components

-

Automatic Greasing Systems: Ensure consistent lubrication with electric drive grease pumps equipped with sensors, standard on MSO mixers.

-

SuperWash Cleaning Systems: Maintain cleanliness with high-pressure, self-retracting wash heads, available for MSO mixers.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...