WAM

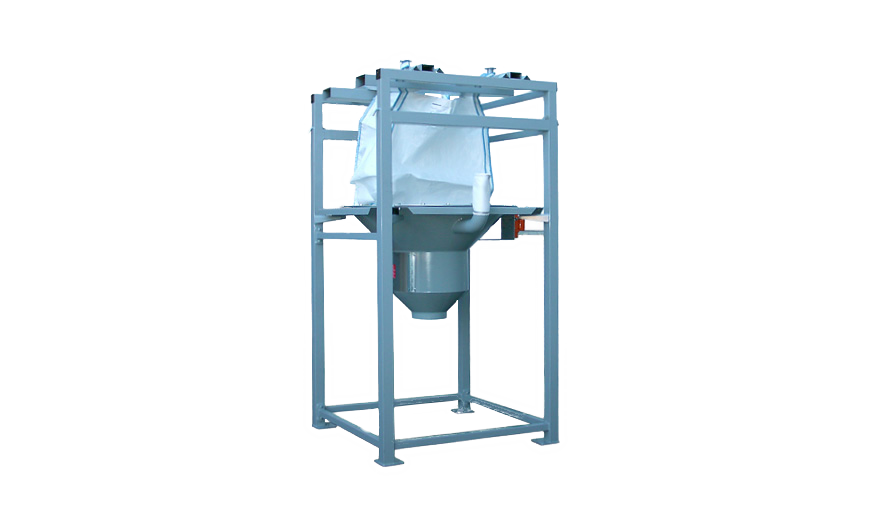

WAM SBB Series FIBC (Flexible Intermediate Bulk Container) Discharging Station

WAM SBB Series FIBC (Flexible Intermediate Bulk Container) Discharging Station

The WAM SBB Series FIBC Discharging Station is designed for the efficient and dust-free emptying of bulk bags (FIBCs) containing powdery or granular materials. This station plays a crucial role in industries handling bulk solids, such as cement processing.

Key Features and Functions:

-

FIBC Support Frame: A robust frame securely holds and supports the FIBC during the discharging process.

-

Discharge Hopper: Located beneath the FIBC, the hopper collects material as it is discharged from the bag.

-

Dust-Free Discharging: Features to minimize dust emissions during the discharging process, creating a cleaner and safer working environment. This includes sealed connections between the FIBC and the hopper.

-

Vibration System (Optional): An optional vibration system assists in promoting material flow from the FIBC into the hopper, ensuring complete emptying.

-

Adjustable Height (Optional): Some SBB models offer adjustable height to accommodate different FIBC sizes.

-

Discharge Outlet: The hopper’s discharge outlet can be connected to a conveying system or collection container for further processing or transport.

-

Control Panel: An electrical control panel provides easy operation and monitoring of the discharging process.

Applications:

-

Primarily used for emptying FIBCs containing materials like cement, lime, fly ash, and other bulk solids.

Relevance

-

Emptying Bulk Cement Bags: The SBB discharging station efficiently empties FIBCs containing cement into downstream processes.

-

Dust Reduction: Cement dust is a significant environmental and health hazard. The SBB’s dust control features minimize emissions, contributing to a cleaner and safer working environment.

-

Improved Material Handling: The SBB streamlines the FIBC emptying process, improving ergonomics and reducing the need for manual labor.

-

Controlled Material Discharge: The hopper and discharge outlet ensure a controlled and consistent flow of cement into downstream systems.