Putzmeister

Putzmeister® Temperature Transmitters Series for Concrete Pumps

Putzmeister® Temperature Transmitters Series for Concrete Pumps

The Temperature Transmitters Series for Putzmeister® concrete pumps offers a robust range of industrial-grade sensors engineered to monitor the temperature of hydraulic oil, engine coolant, exhaust gases, and key mechanical components. These sensors deliver critical data to the control system, enabling intelligent thermal regulation, preventing overheating, and safeguarding the pump's performance and longevity—whether operating in Burnaby or on construction sites worldwide.

🔧 Key Features & Benefits

-

Accurate Temperature Sensing

Provides highly precise temperature readings essential for real-time monitoring and decision-making by the control system. -

Intelligent Signal Output

Converts temperature readings into standard electrical signals (voltage or current) for seamless integration into the pump’s electronic control unit (ECU). -

Thermal Protection Logic

Enables automatic responses to high-temperature conditions—such as activating a hydraulic cooler or triggering a shutdown alert to prevent catastrophic failure. -

Optimized Performance

Helps maintain components within optimal thermal ranges, ensuring efficient pump operation and fluid performance (especially for hydraulic oil). -

Heavy-Duty Construction

Built to endure harsh concrete pumping environments—resistant to vibration, fluid exposure, and extreme temperatures. -

Versatile Options

Available in multiple sensor technologies (thermistors, RTDs, thermocouples), thread sizes (including M14x1.5), and preset switching points (like 55°C) to suit a variety of system needs. -

Plug-and-Play Compatibility

Designed specifically for Putzmeister® control systems—ensuring easy installation and full system compatibility.

🔍 Component Overview (Based on Images)

-

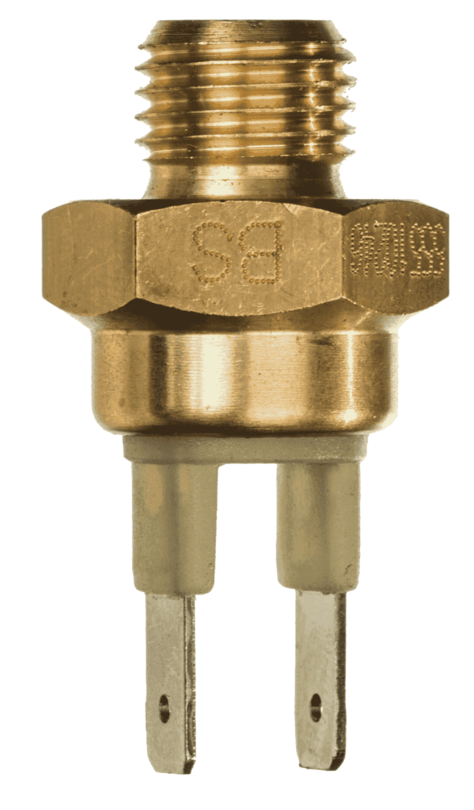

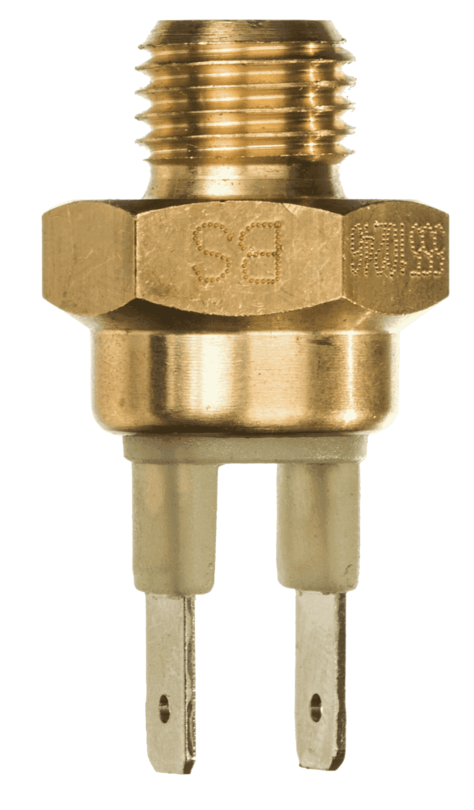

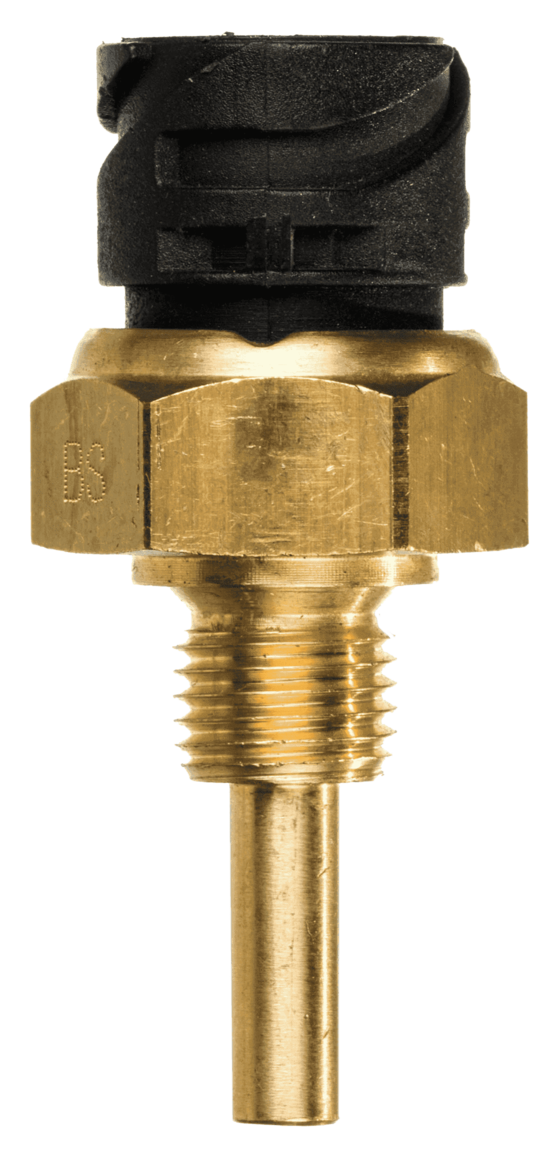

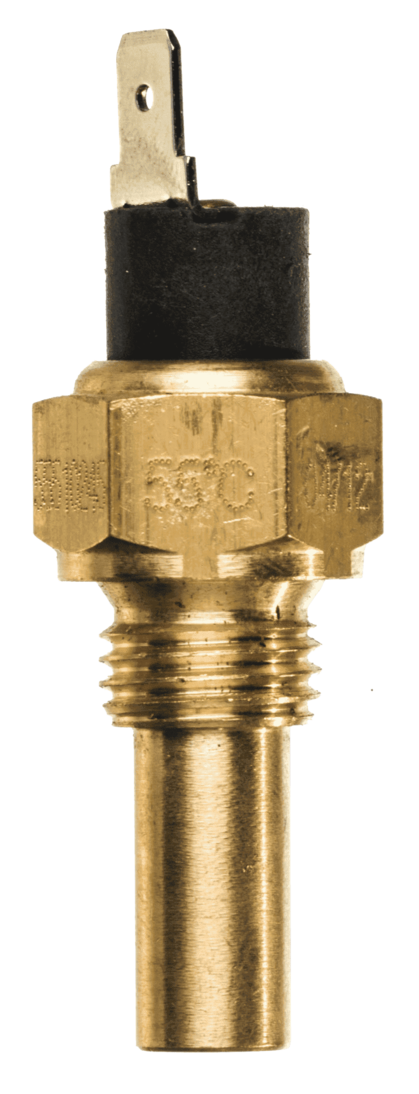

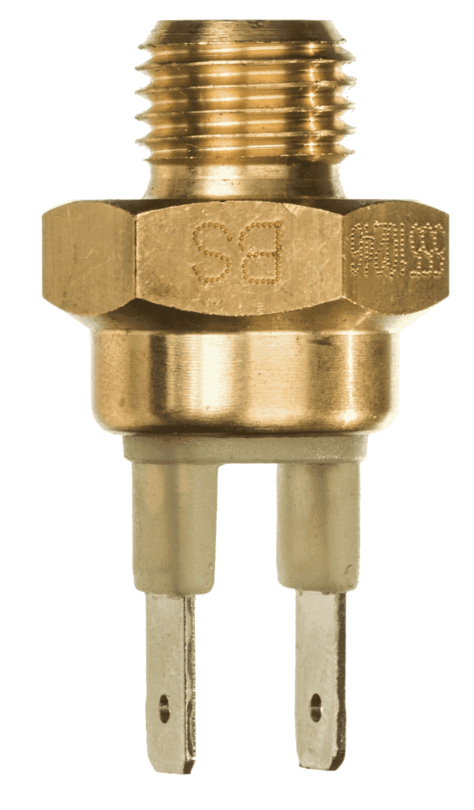

Brass Temperature Transmitter (Large Left Image):

A common model featuring a threaded M14x1.5 connection and likely a preset switching point of 55°C. This sensor is used to monitor hydraulic oil or coolant temperatures and initiate a response when thresholds are exceeded. -

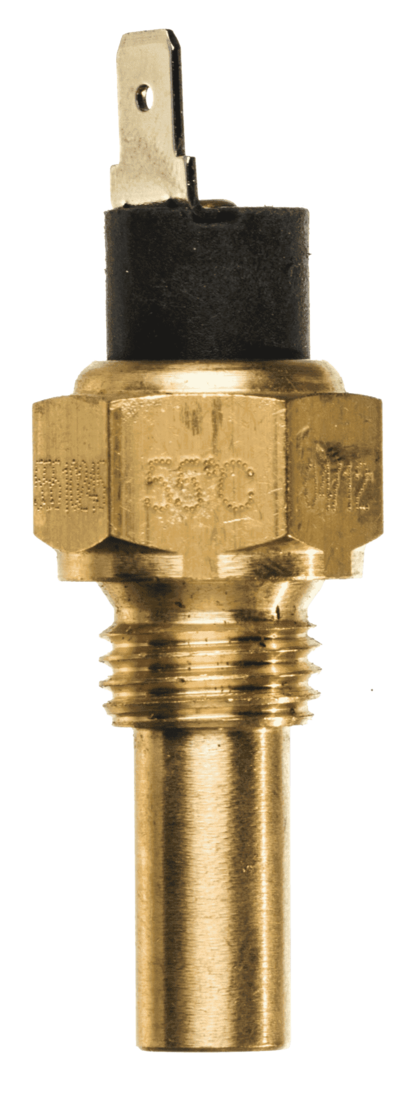

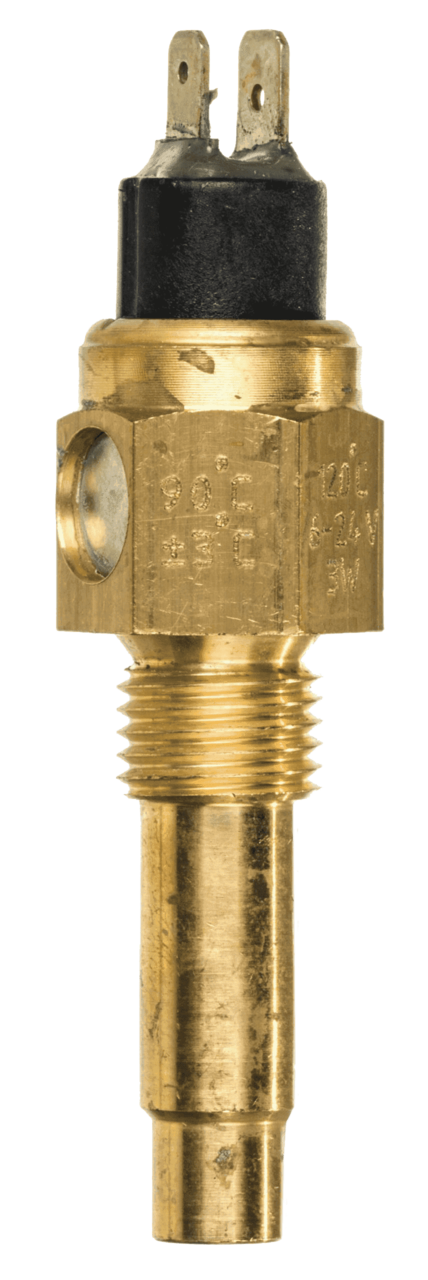

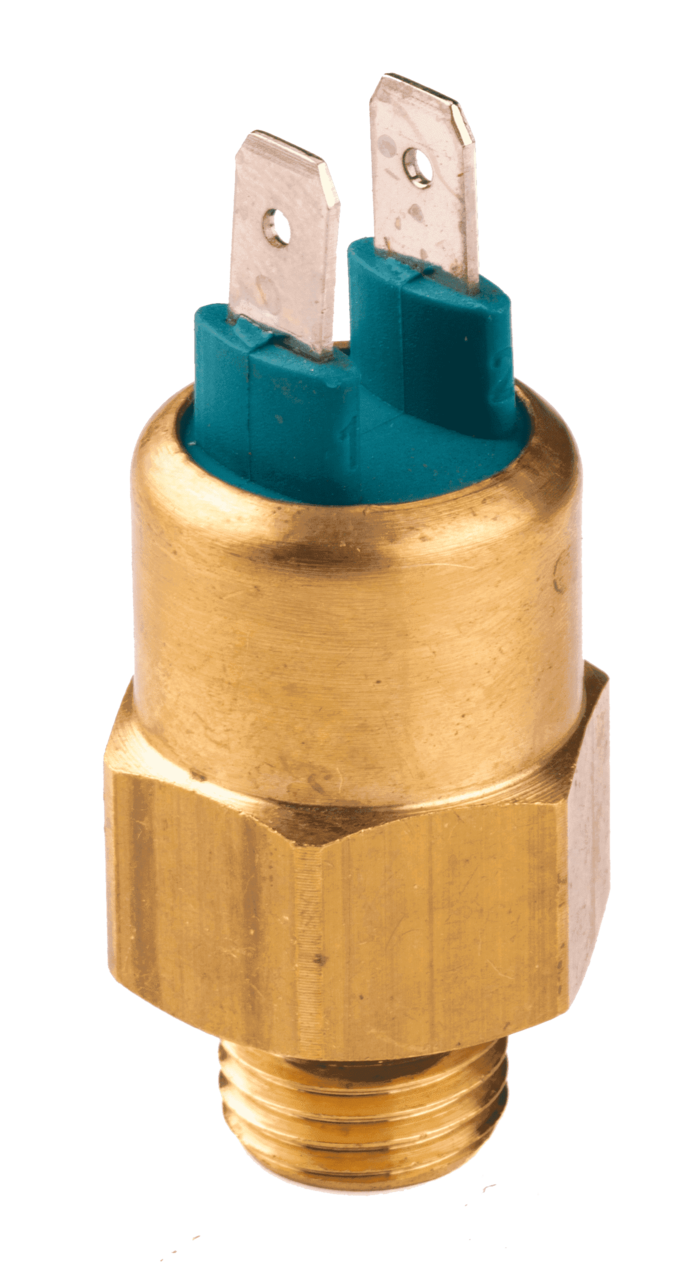

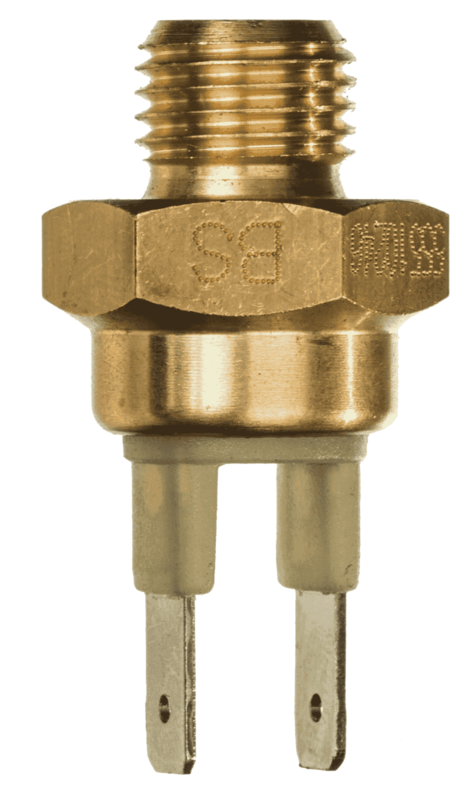

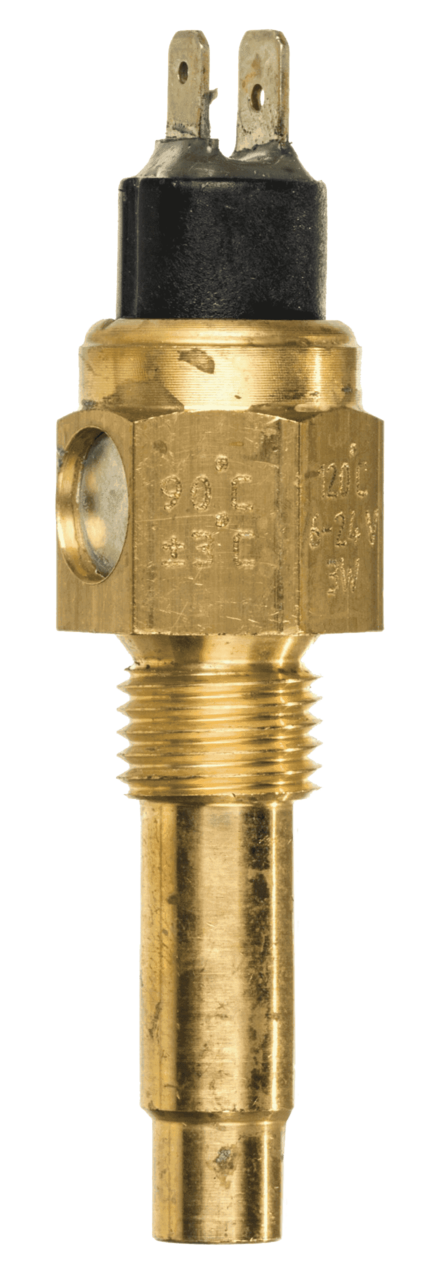

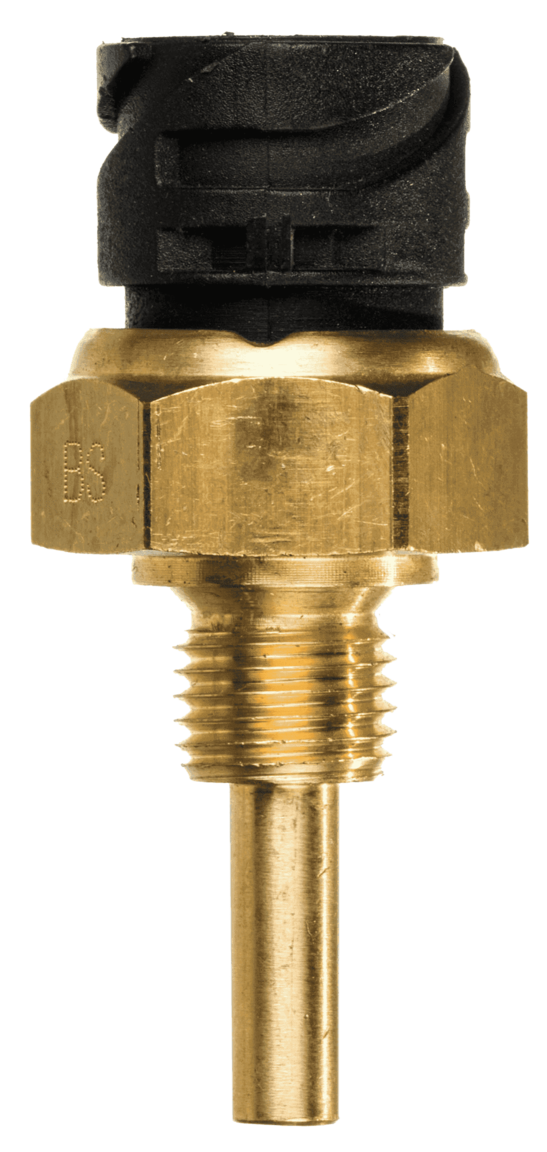

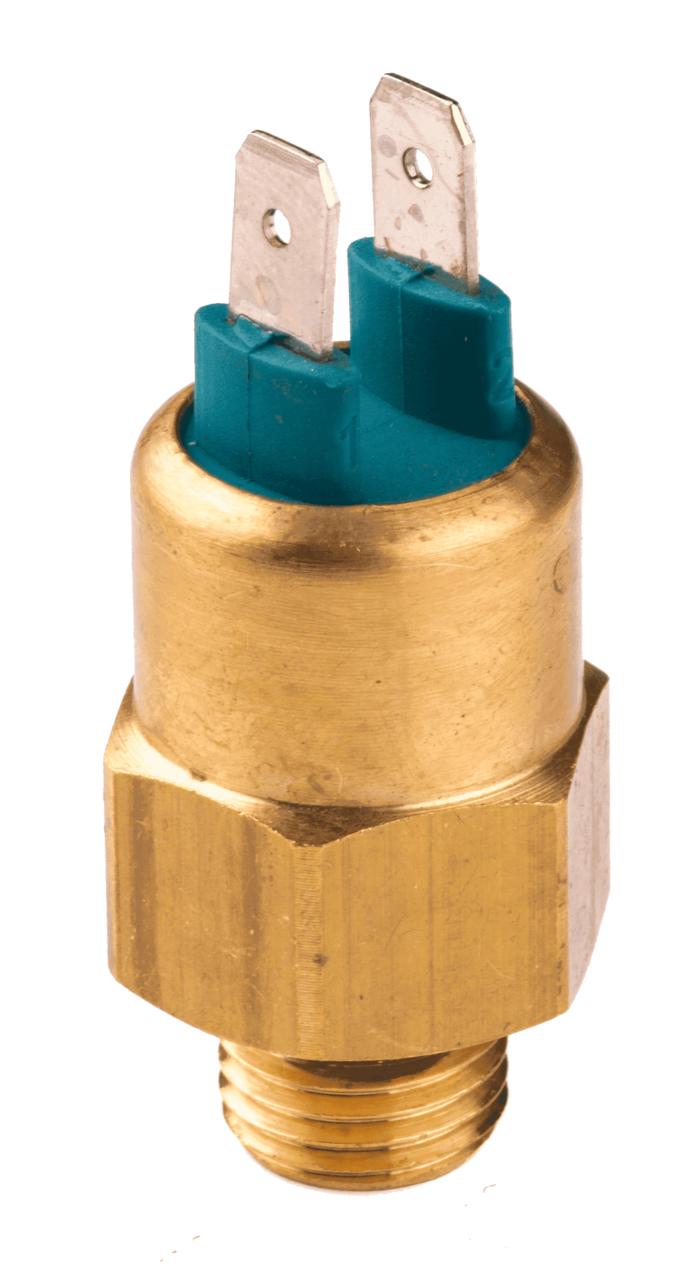

Additional Temperature Sensor Variants (Right Images):

Include models with different probe lengths, body materials, and electrical terminal types. These may be designed for use in:-

Hydraulic circuits

-

Engine cooling systems

-

Ambient air monitoring

-

Surface or immersion sensing

-

Some are designed for screw-in applications (into a port or housing), while others are clamp-on or external surface sensors.

🏗️ Application within Putzmeister® Concrete Pumps

These sensors serve as thermal sentinels across multiple systems:

| 🔍 Monitoring Target | ⚙️ Function of Transmitter |

|---|---|

| Hydraulic Oil | Triggers coolers or shutdown warnings if oil exceeds 55°C (or other setpoint) |

| Engine Coolant | Maintains proper combustion temps and prevents engine overheating |

| Exhaust Gas | Detects anomalies and optimizes fuel-air mix in advanced models |

| Bearing Assemblies | Prevents failure by tracking excessive heat in high-friction areas |

| Ambient Environment | Informs system adjustments or displays for operator awareness |

✅ Why Temperature Monitoring Matters for Concrete Pumping

-

🚫 Avoids Costly Downtime

Prevents damage to critical systems like the hydraulic pump or engine, reducing service costs. -

⚙️ Ensures Consistent Operation

Keeps system fluids within safe temperature ranges, avoiding performance dips. -

🔒 Protects Your Investment

Extends the life of expensive components by alerting operators to thermal stress early. -

🔥 Enhances On-Site Safety

Prevents hazardous overheating conditions, contributing to overall job site safety.

📘 Compatibility & Part Selection Guidance

When choosing the right temperature transmitter, especially for replacements or upgrades in models like the Putzmeister® BSF, MXR, or TK series, always verify:

-

✅ Thread type and size (e.g., M14x1.5)

-

✅ Electrical output (voltage, resistance, or current)

-

✅ Temperature range or fixed switching point (e.g., 55°C)

-

✅ Intended mounting method (immersion, surface, ambient)

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...