Putzmeister

Putzmeister® Rings and Plates Series for Concrete Pumps

Putzmeister® Rings and Plates Series for Concrete Pumps

Ensure long-lasting performance and system integrity with the Putzmeister® Rings & Plates Series, a collection of essential wear and sealing components designed to protect and support the core operating systems of your concrete pump. Engineered for durability, precision, and compatibility, these parts play a critical role in maintaining hydraulic efficiency, structural alignment, and component longevity under demanding jobsite conditions.

🔧 Key Features & Benefits

-

Advanced Wear Protection

Precision wear rings and plates safeguard vital components—such as pistons, cylinder walls, and S-valve housings—from abrasion caused by concrete and moving parts. -

Leak-Free Sealing

Includes O-rings, sealing rings, gaskets, and backup rings to ensure fluid-tight connections in both hydraulic and concrete delivery systems. -

Structural Support & Alignment

Mounting and support plates maintain proper positioning and secure attachment of major assemblies including hoppers, cylinders, and valve mechanisms. -

OEM Fit & Function

All components are manufactured to exact Putzmeister® specifications for direct replacement and seamless performance in existing pump systems. -

Durable Materials

Constructed from wear-resistant metals and high-performance polymers that withstand the high pressure, abrasion, and mechanical stress of concrete pumping.

🧩 Component Overview

-

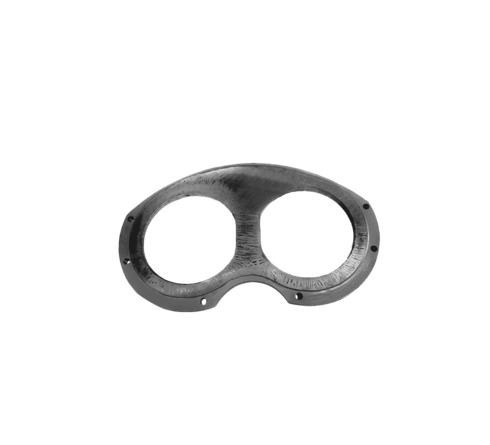

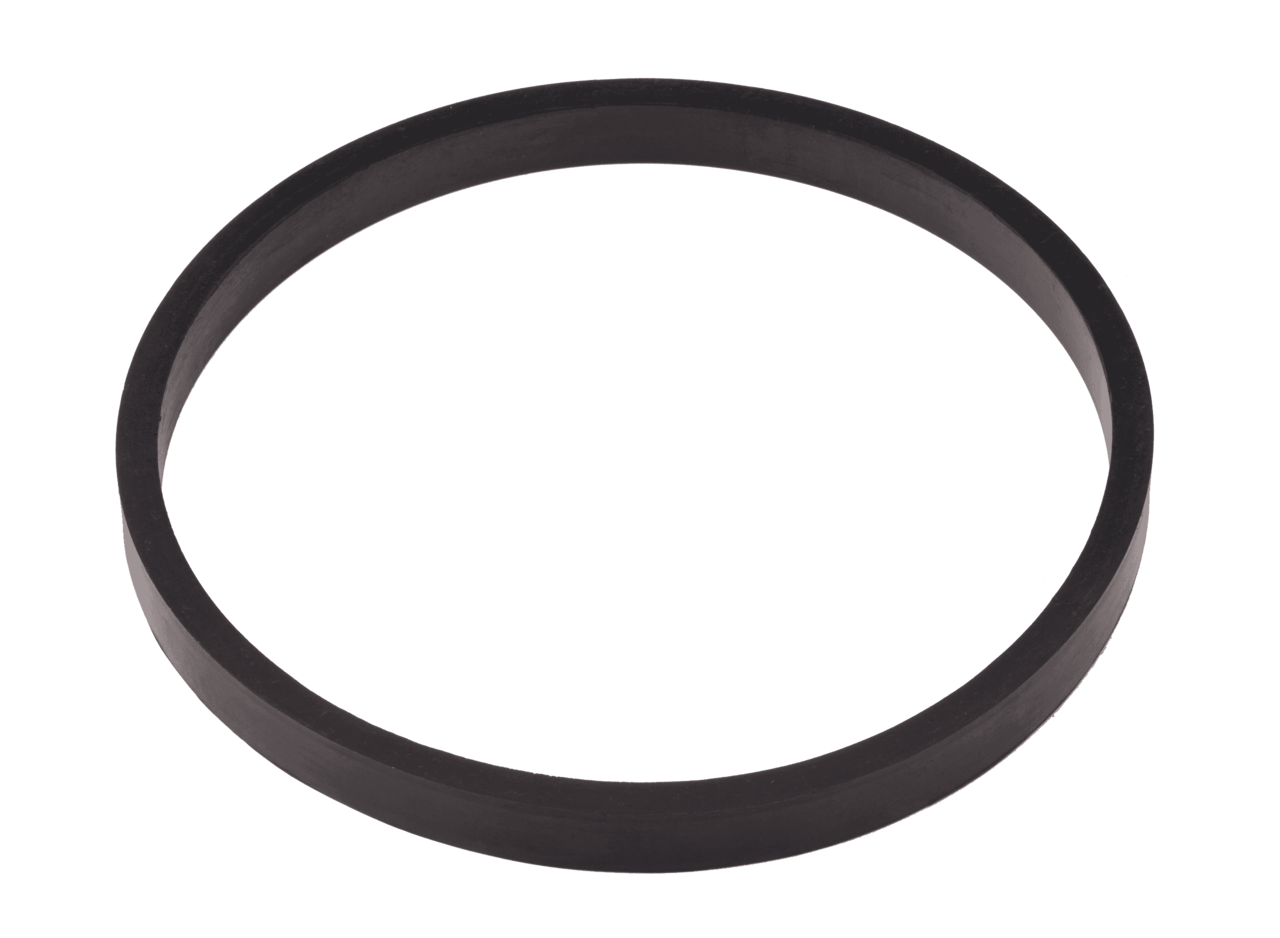

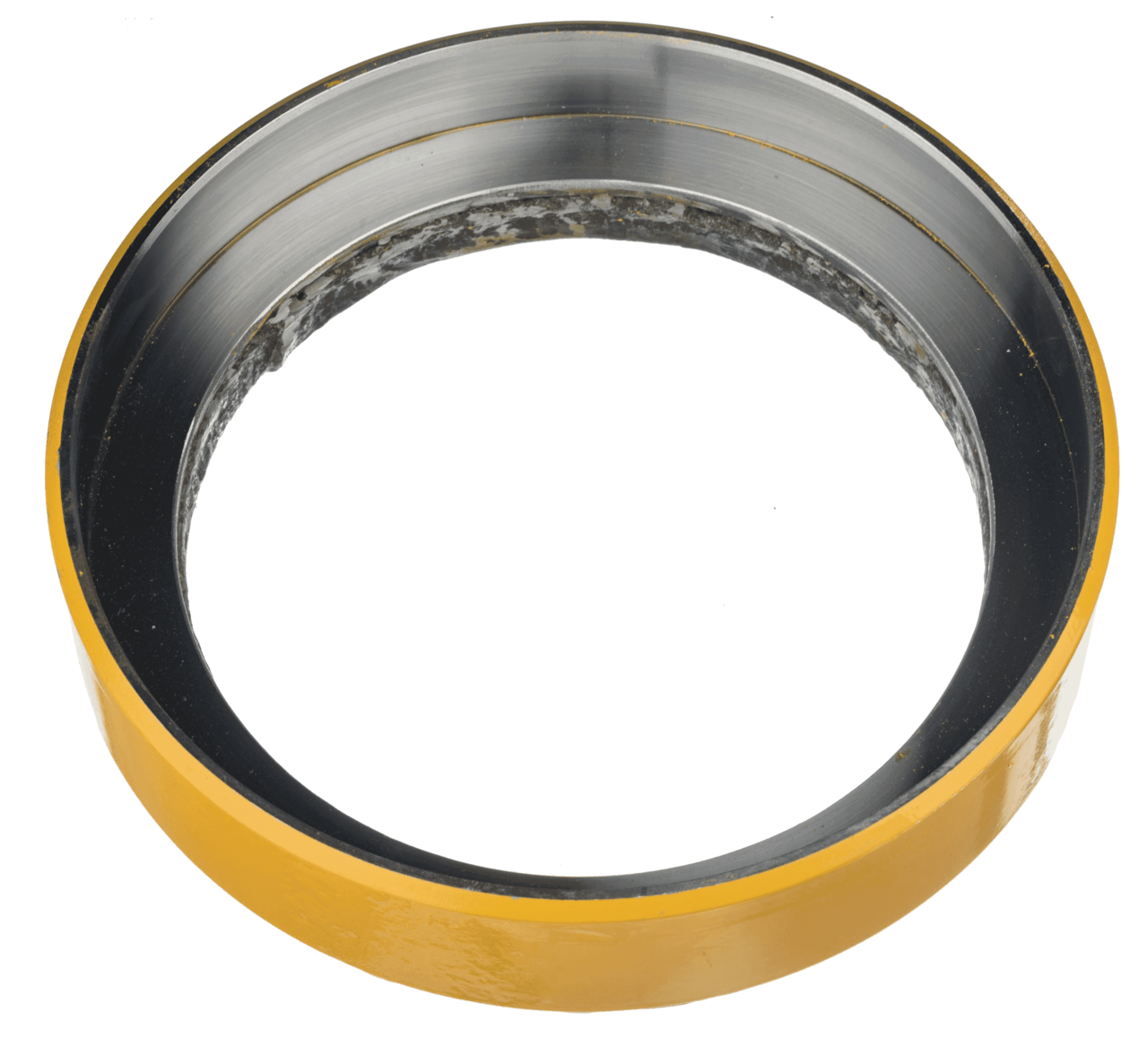

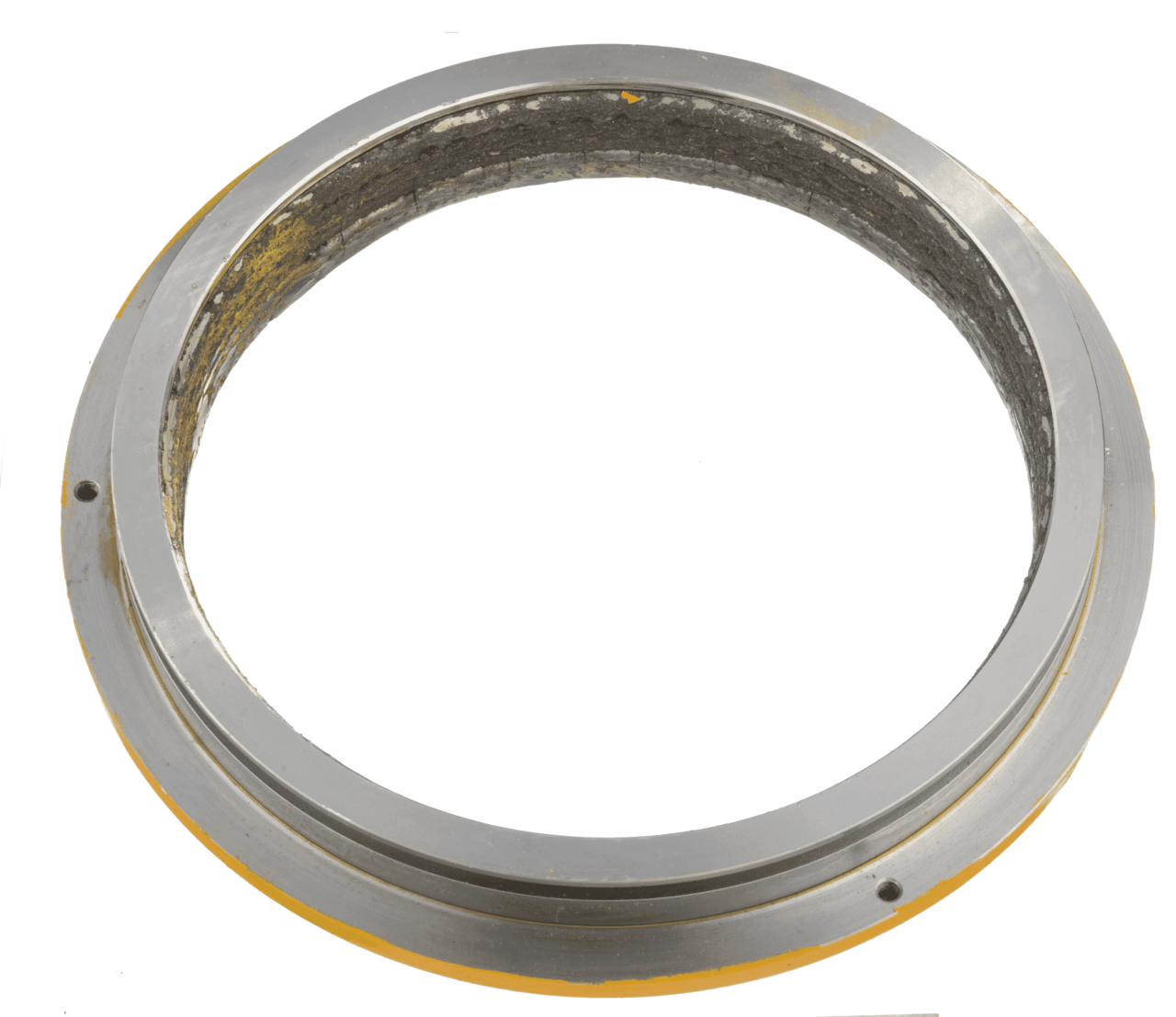

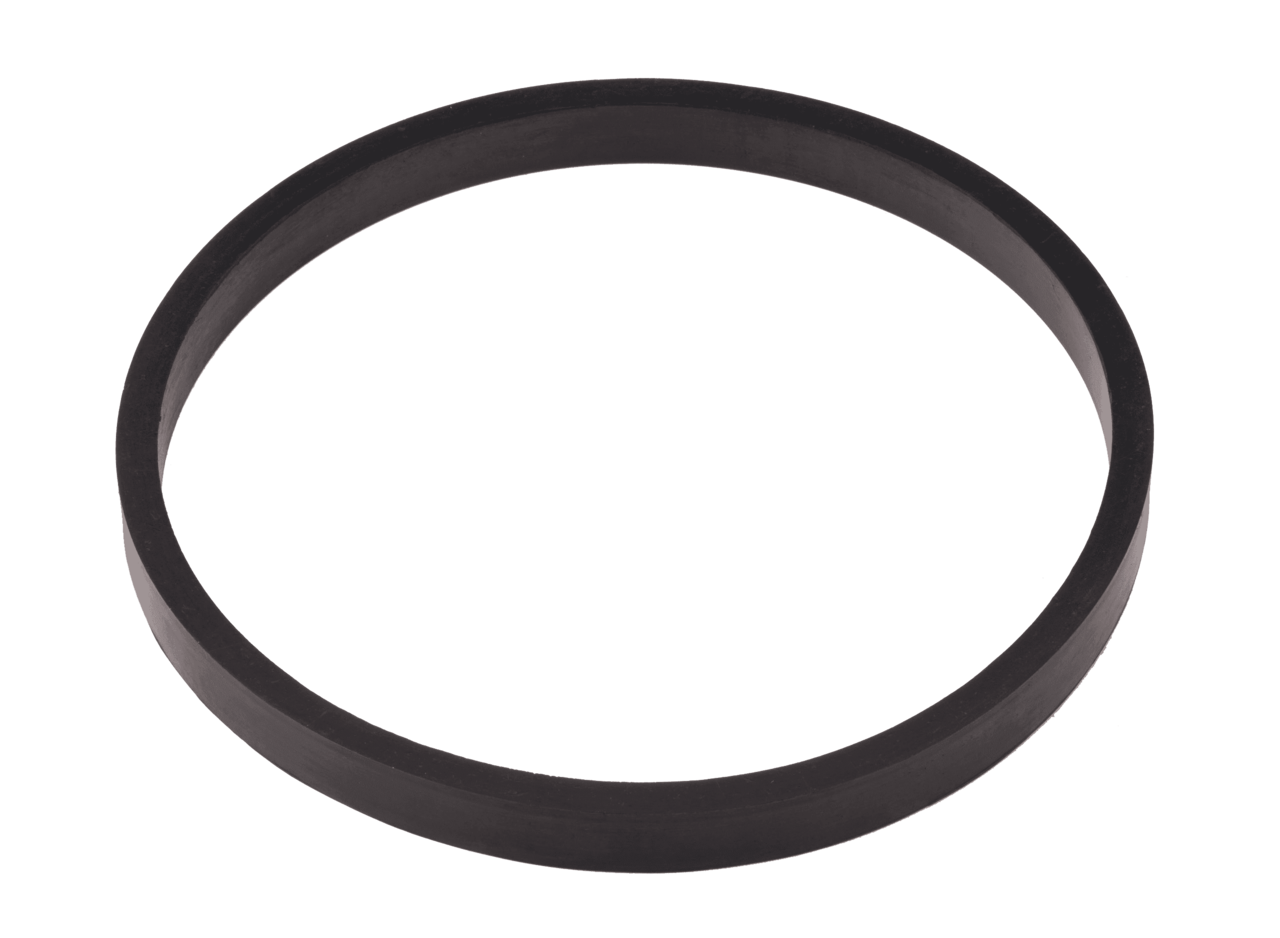

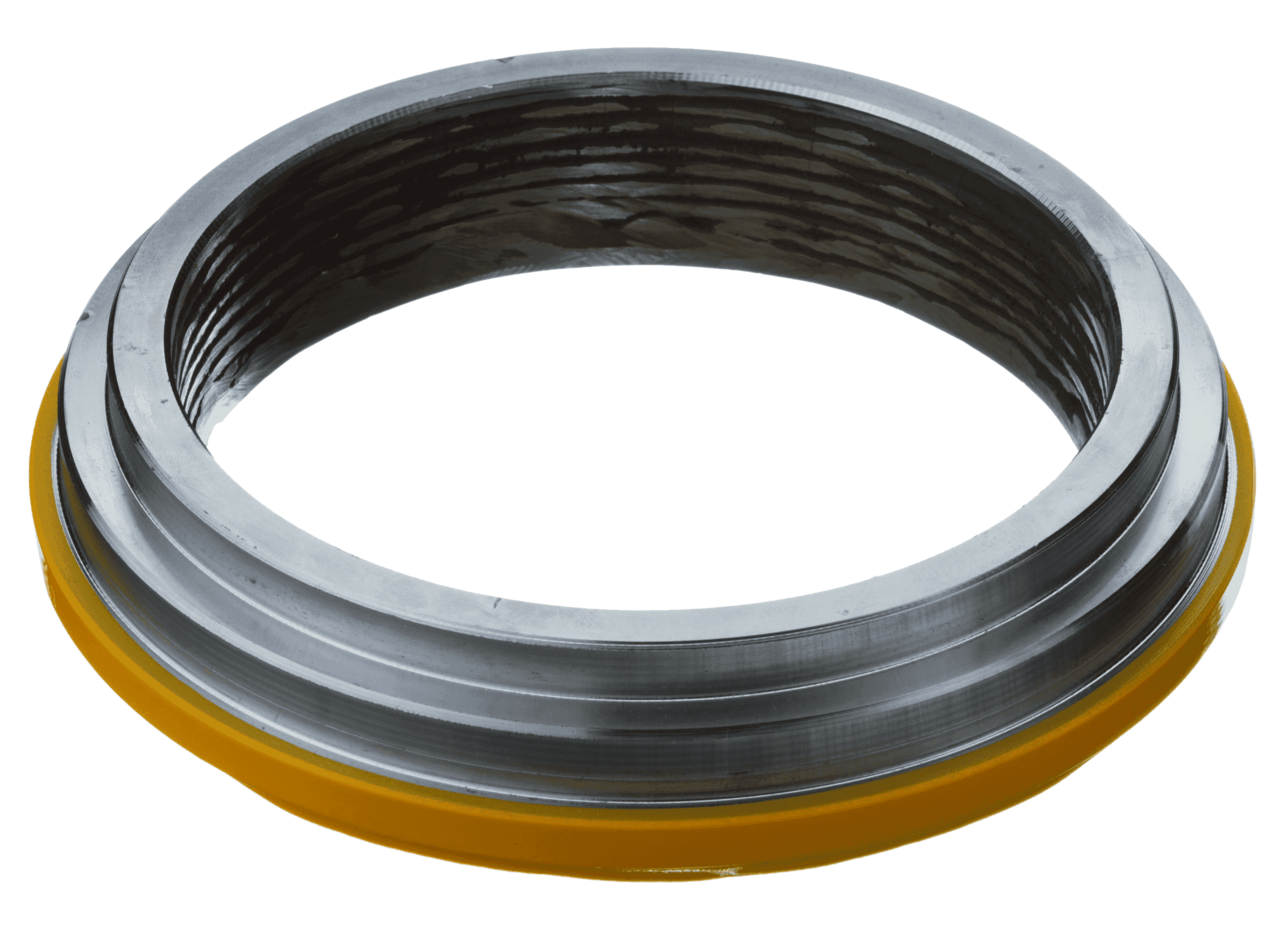

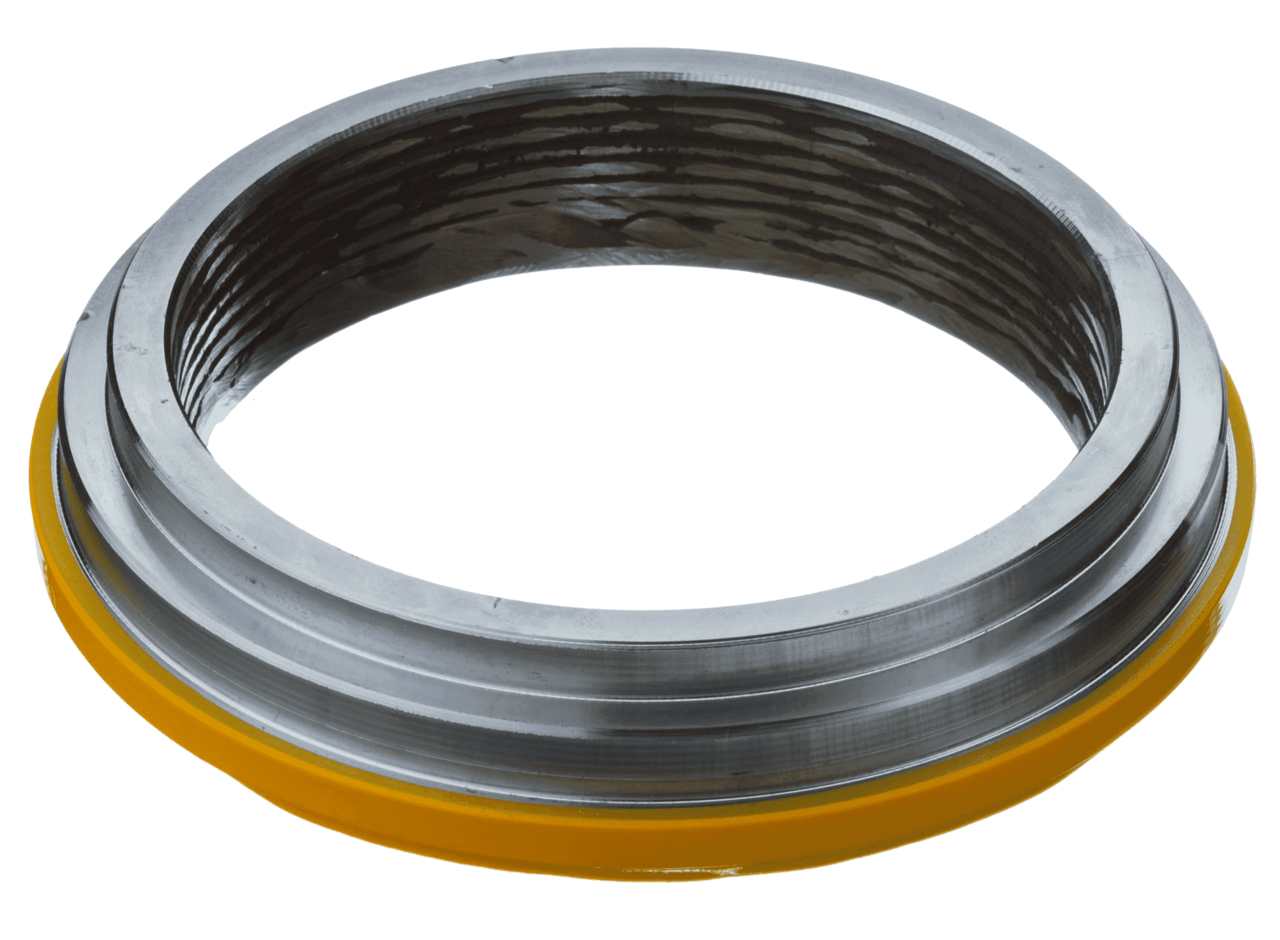

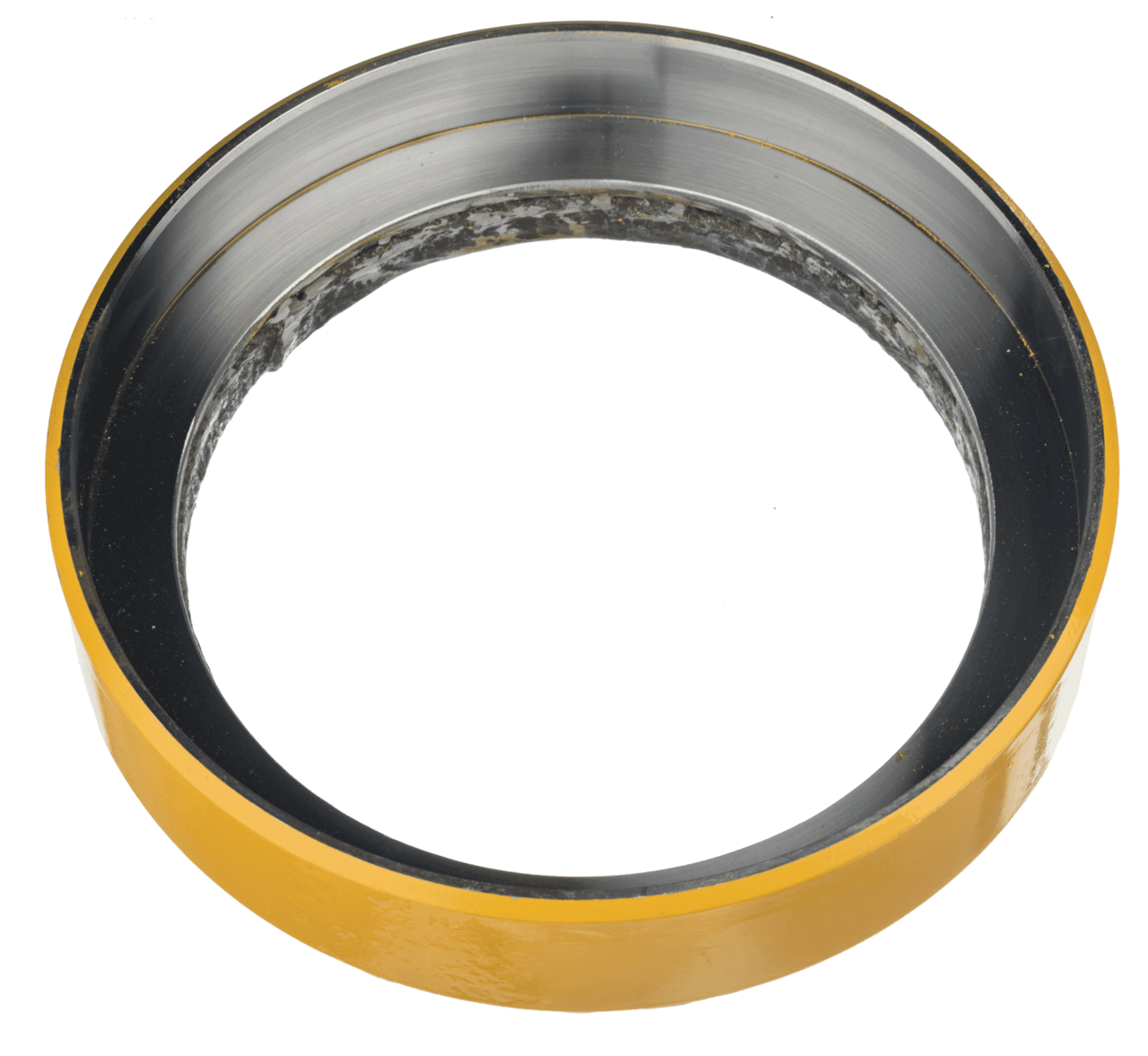

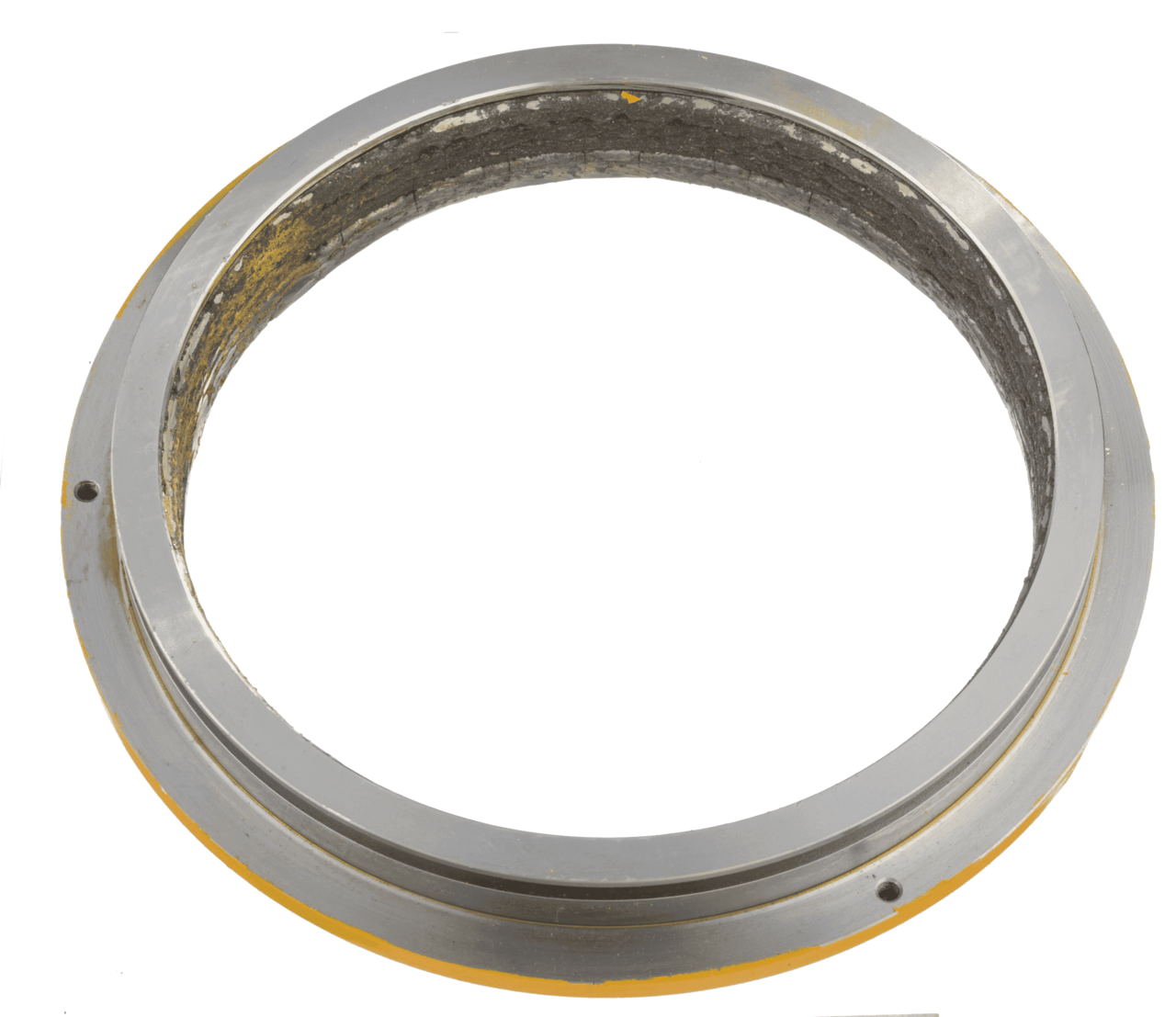

Wear Rings

Designed to guide the pistons within the main pumping cylinders while protecting the cylinder walls from friction and wear. Often include lubrication grooves for smooth operation. -

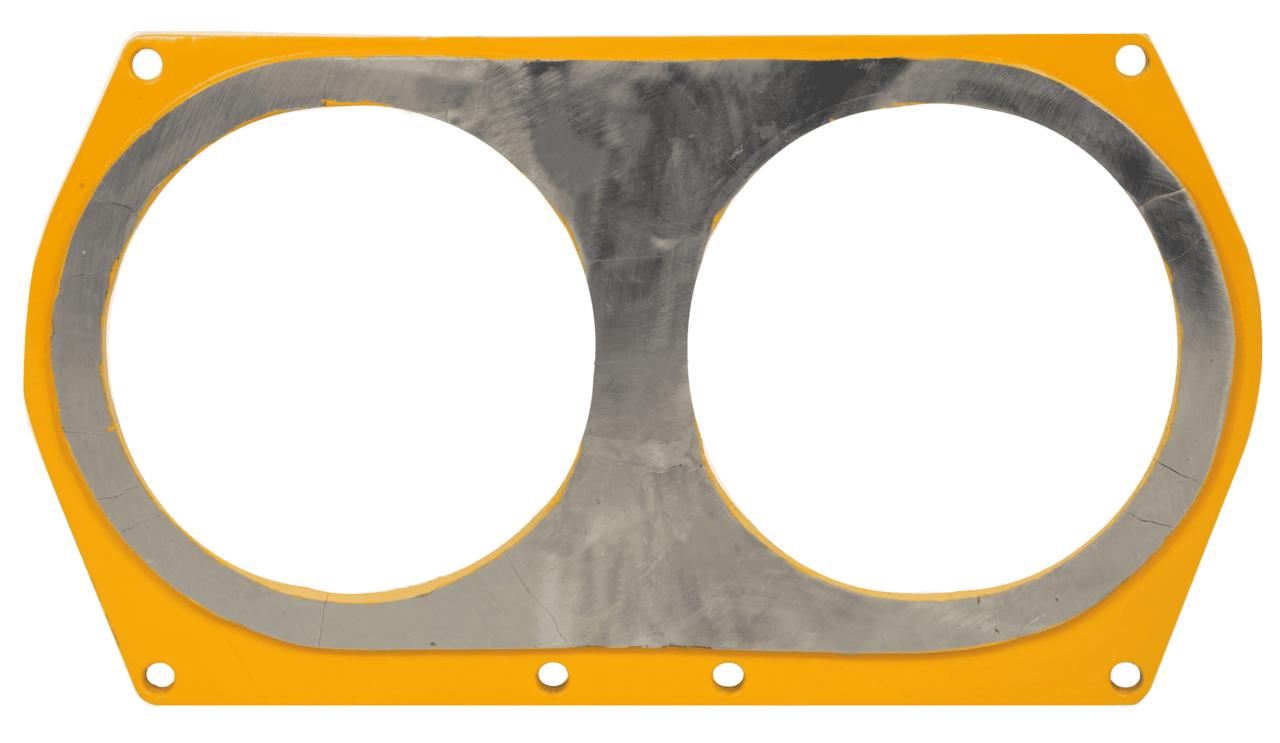

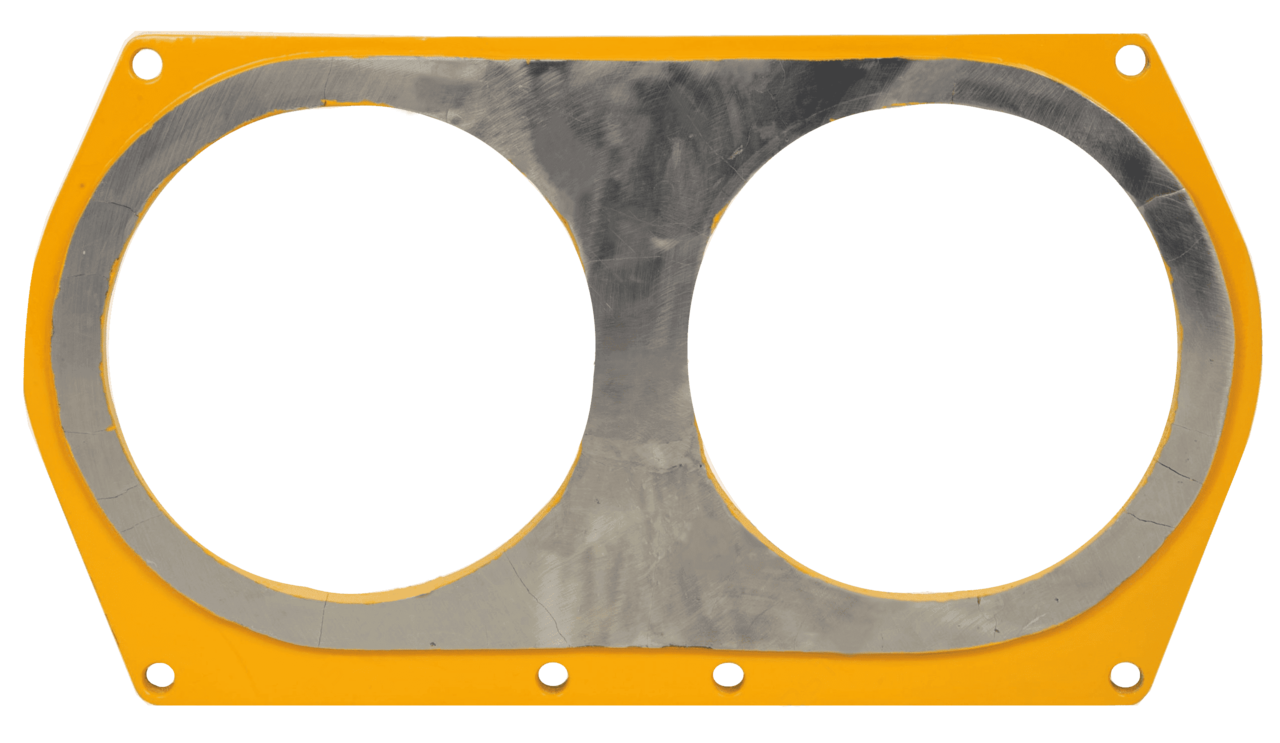

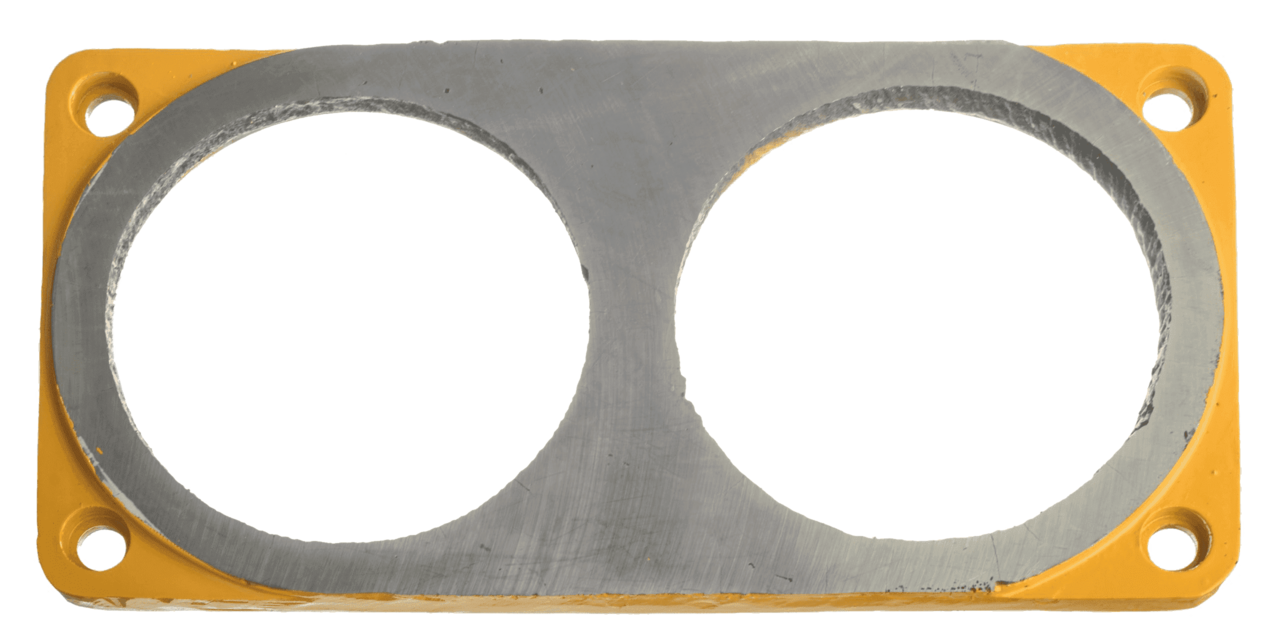

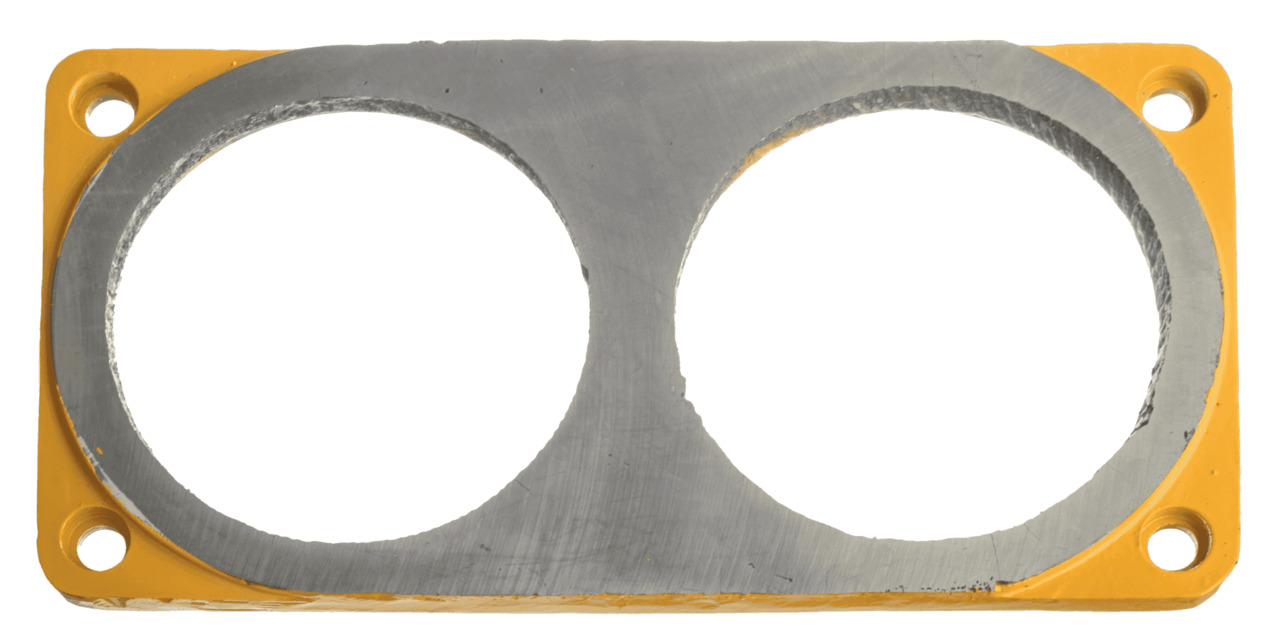

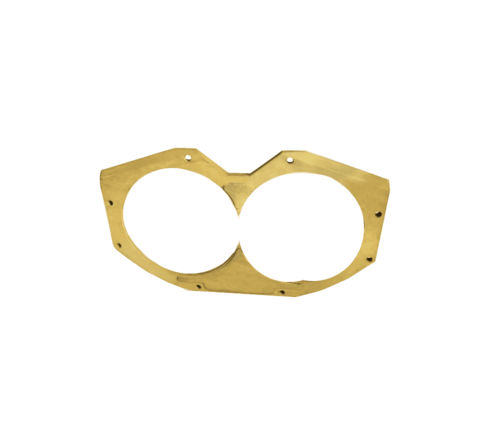

Figure-Eight Wear Plates

Typically installed in the S-valve area. These plates protect the valve housing where concrete flow diverges, making them highly resistant to abrasion. -

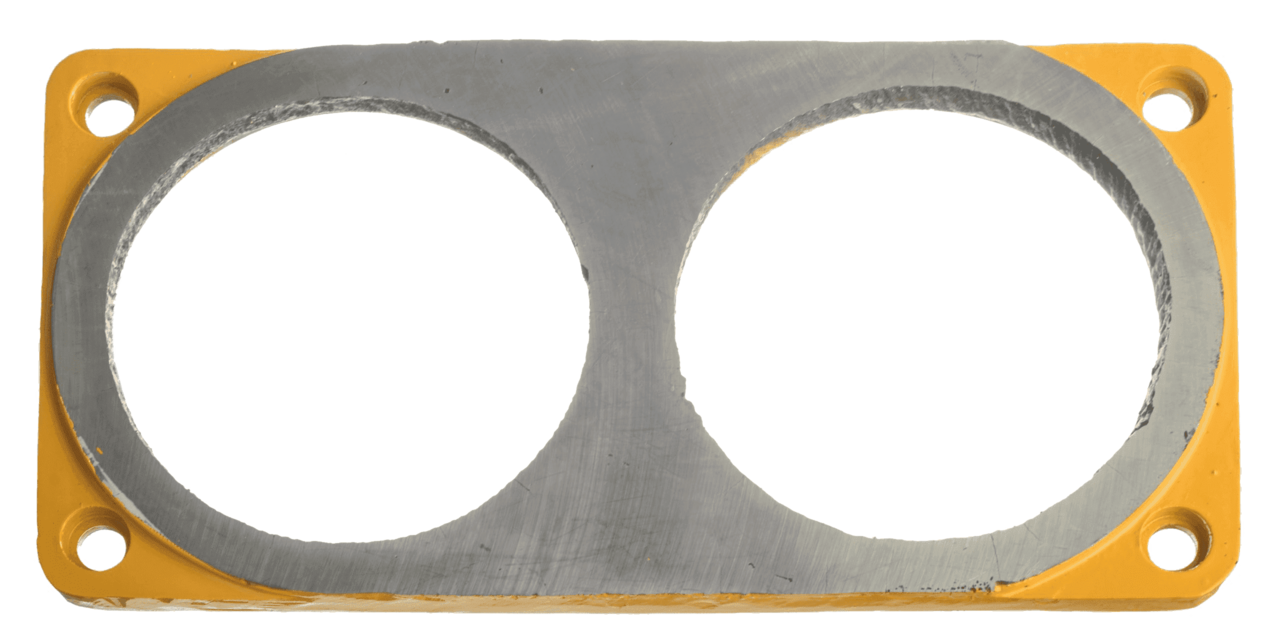

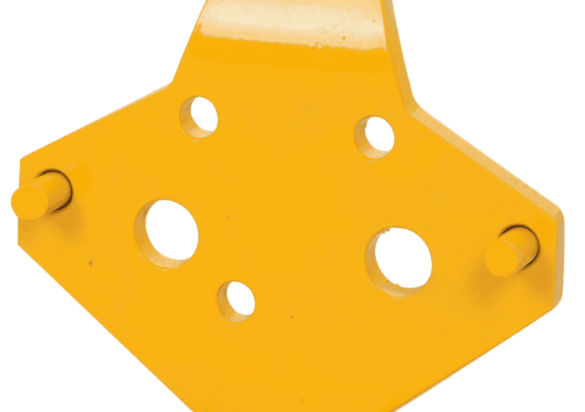

Yellow Mounting/Support Plates

Heavy-duty structural plates used to secure various components—such as the hopper or valve assemblies—to the pump frame. -

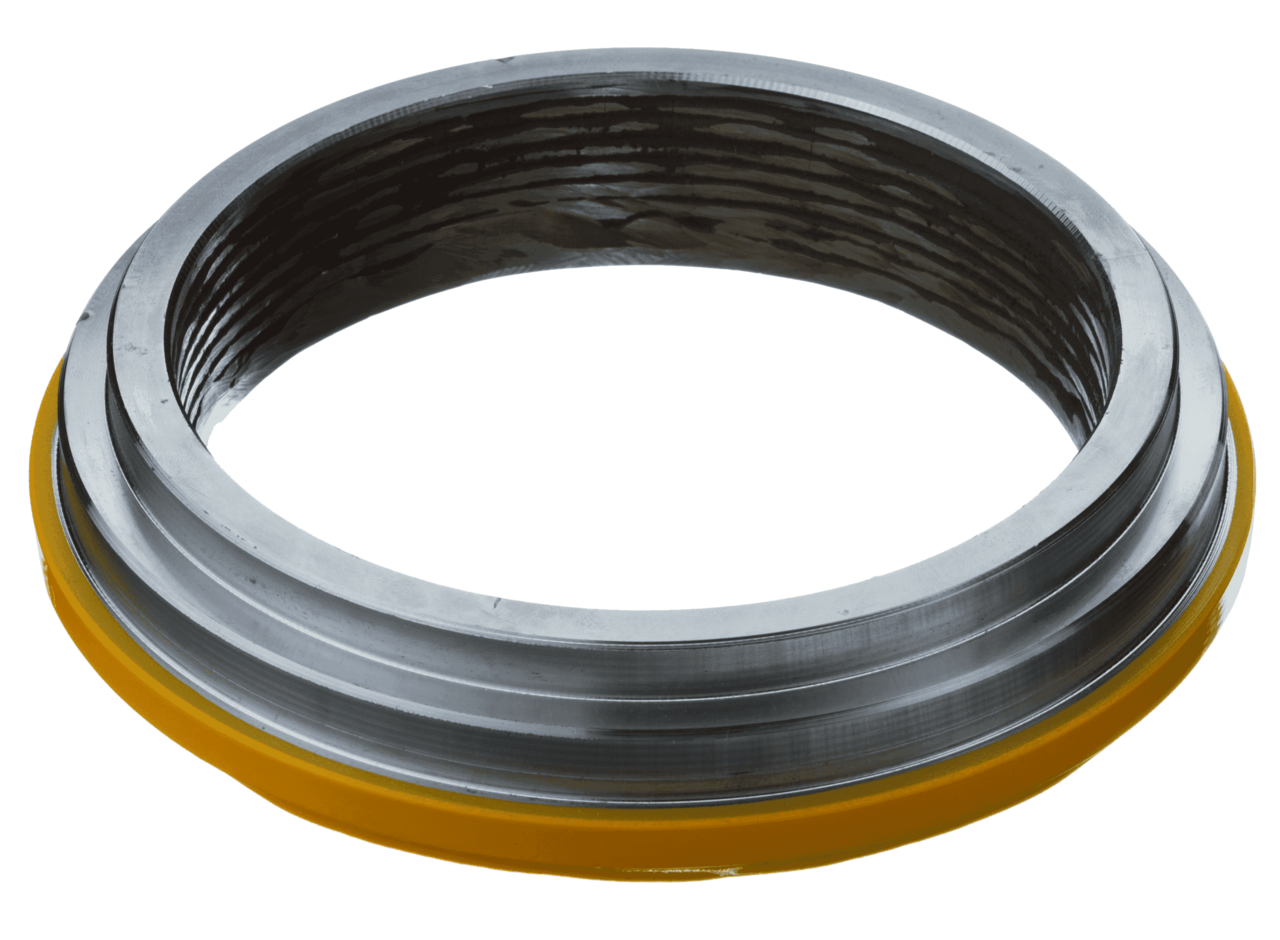

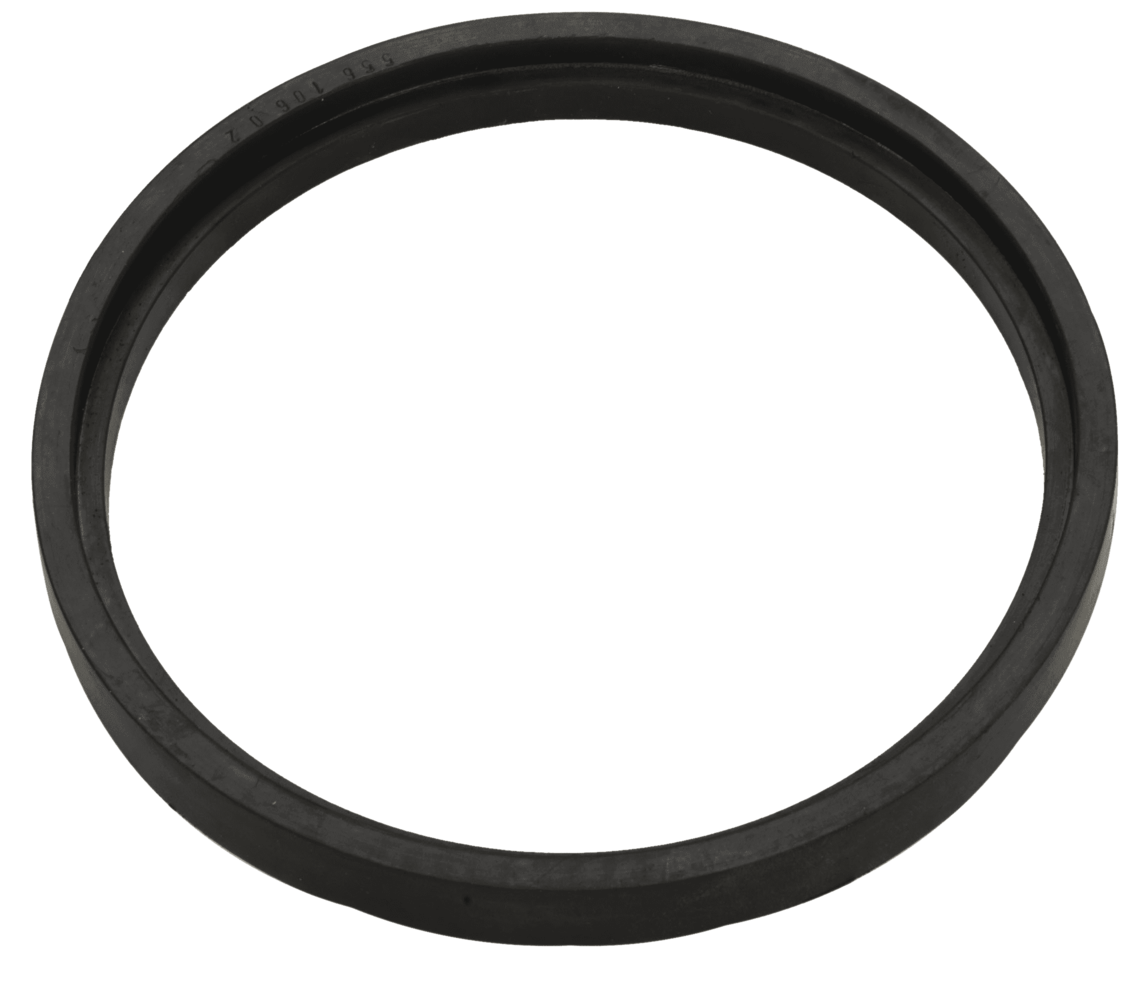

Metallic Seal Retainer Rings

Support elastomeric seals in high-pressure applications and prevent seal extrusion or displacement during operation. -

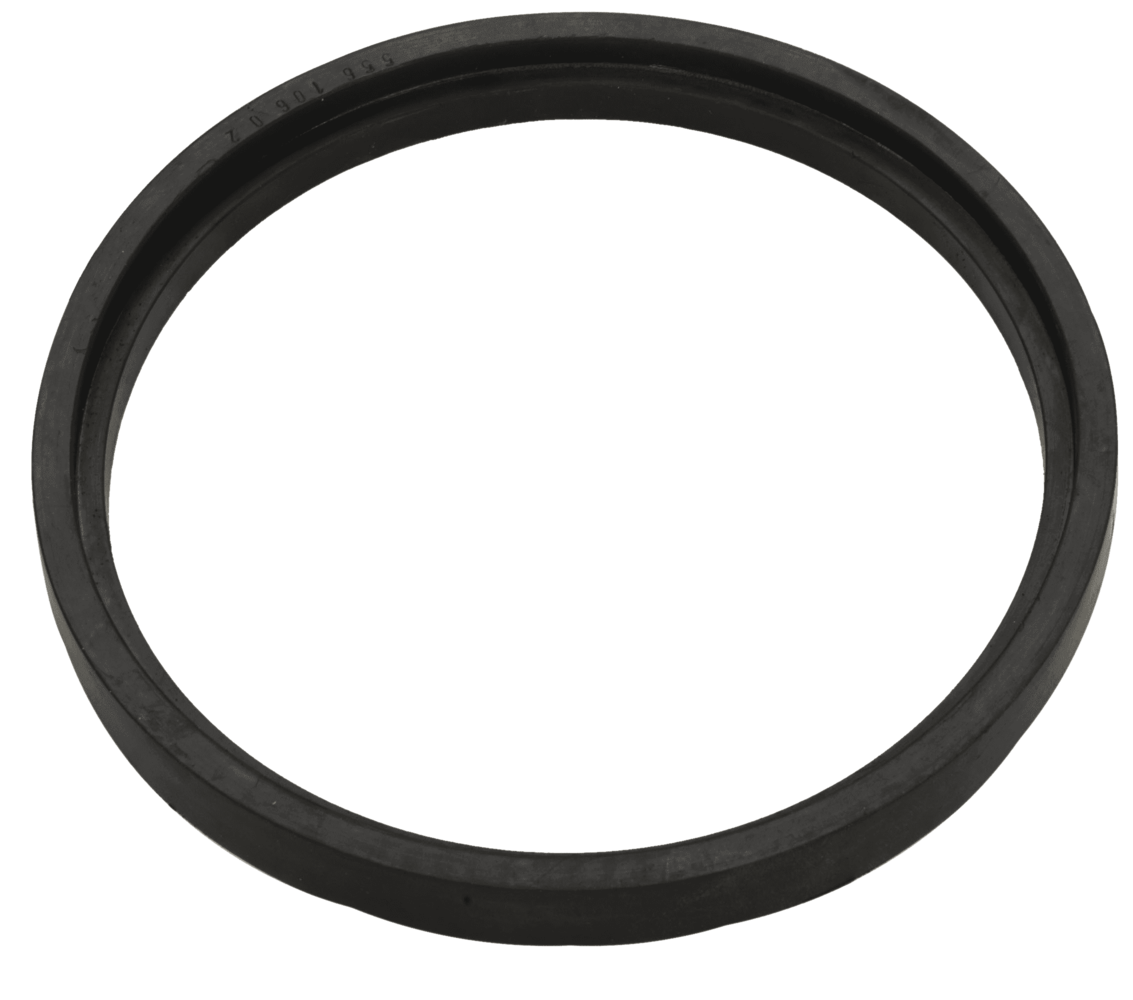

O-Rings & Sealing Rings

Provide sealing in both static and dynamic applications. Common in hydraulic cylinders, pump housings, and line connections. -

Gaskets

Flat sealing components placed between flanges or surfaces to prevent hydraulic oil or slurry leakage under compression.

🏗️ Function Within the Pump System

-

Wear Rings:

Protect pumping cylinders and pistons from premature wear while guiding movement. -

Figure-Eight Wear Plates:

Shield the S-valve chamber from the high friction of flowing concrete. -

Mounting Plates:

Ensure firm, aligned installation of critical subassemblies. -

Sealing Rings, O-Rings & Gaskets:

Maintain leak-proof hydraulic and delivery systems by sealing critical joints and surfaces. -

Backup Rings / Seal Retainers:

Reinforce soft seals under high pressure and extend system service life.

✅ Why These Components Matter

Failure of even the smallest wear ring or seal can lead to:

-

Hydraulic fluid or concrete leakage

-

Reduced pressure and pumping efficiency

-

Accelerated wear of expensive parts

-

Costly downtime and repair needs

Regular inspection and replacement of rings and plates are essential to maintain high system performance and protect your investment.

📘 Technical Support & Product Matching

To ensure you select the correct Putzmeister® Rings & Plates, refer to the official parts catalog for:

-

Dimensions and material grades

-

Application by pump model

-

Torque and pressure tolerances

-

Component replacement intervals

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...