Putzmeister

Putzmeister® Plunger Cylinders and Accessories Series For Concrete Pump Hydraulic Systems

Putzmeister® Plunger Cylinders and Accessories Series For Concrete Pump Hydraulic Systems

The Plunger Cylinders & Accessories Series is a specialized line of hydraulic actuators used in Putzmeister® concrete pumps. Unlike standard double-acting cylinders, plunger cylinders feature a solid single-rod design extending from one end, optimized for high-load, linear-force applications. They are essential for various secondary operations within the pump system—including valve actuation, linkage control, gate positioning, and other auxiliary movements critical to smooth pump operation.

Engineered by Putzmeister® for durability, precision, and system compatibility, these cylinders ensure long-lasting performance in the demanding conditions of concrete placement - whether in BC, across Canada or the USA, or in challenging industrial sites worldwide.

Key Features & Benefits:

-

✅ Linear Force Application:

Transmits direct hydraulic force to power linear motion systems within the concrete pump. -

🔧 Heavy-Duty Construction:

Fabricated from high-grade steel and designed to withstand the harsh operating pressures typical in concrete pumping environments. -

🎯 Precision Hydraulic Control:

Enables accurate force and motion control, essential for systems requiring dependable repeatability and coordination. -

📐 Multiple Sizes & Configurations:

Available in a range of diameters, stroke lengths, and mounting options (clevis, flange, trunnion, spherical bearing) to suit diverse pump designs. -

💧 Leak-Proof Operation:

Fitted with robust hydraulic seals—including O-rings, U-cups, and rod seals—to prevent fluid leakage under high pressures and variable temperatures. -

🔗 Putzmeister® Integration:

Designed for direct compatibility with Putzmeister® pump models and auxiliary hydraulic systems.

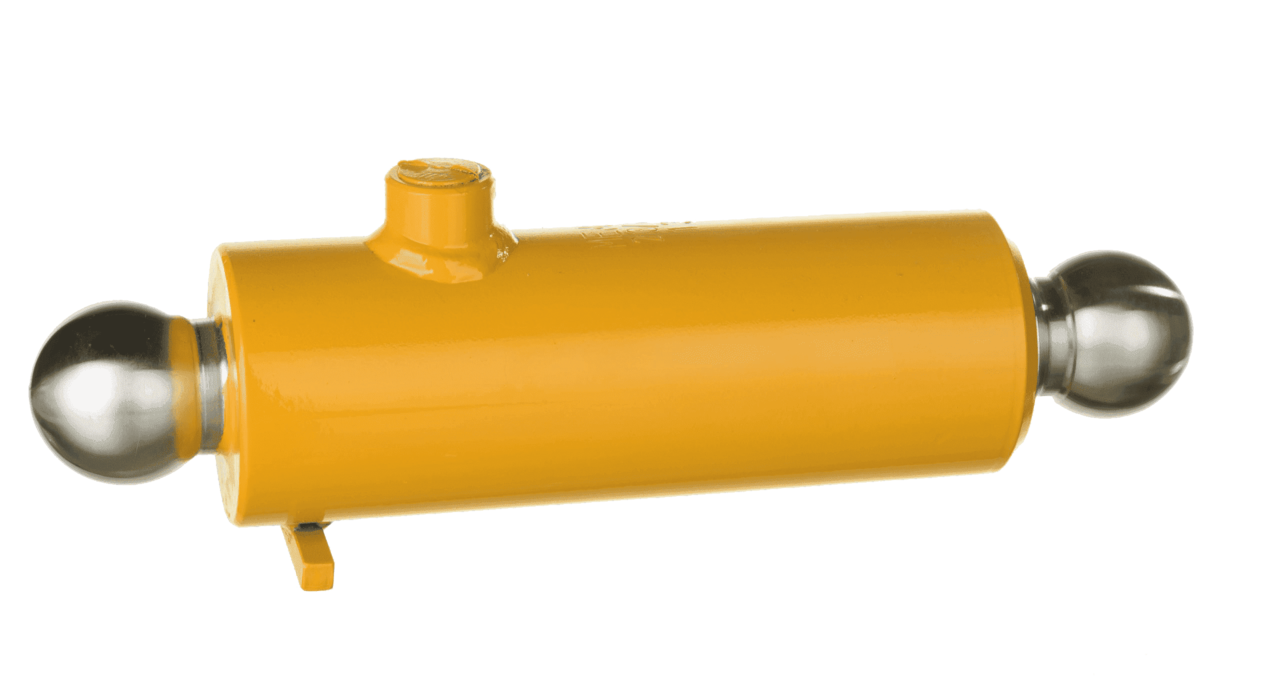

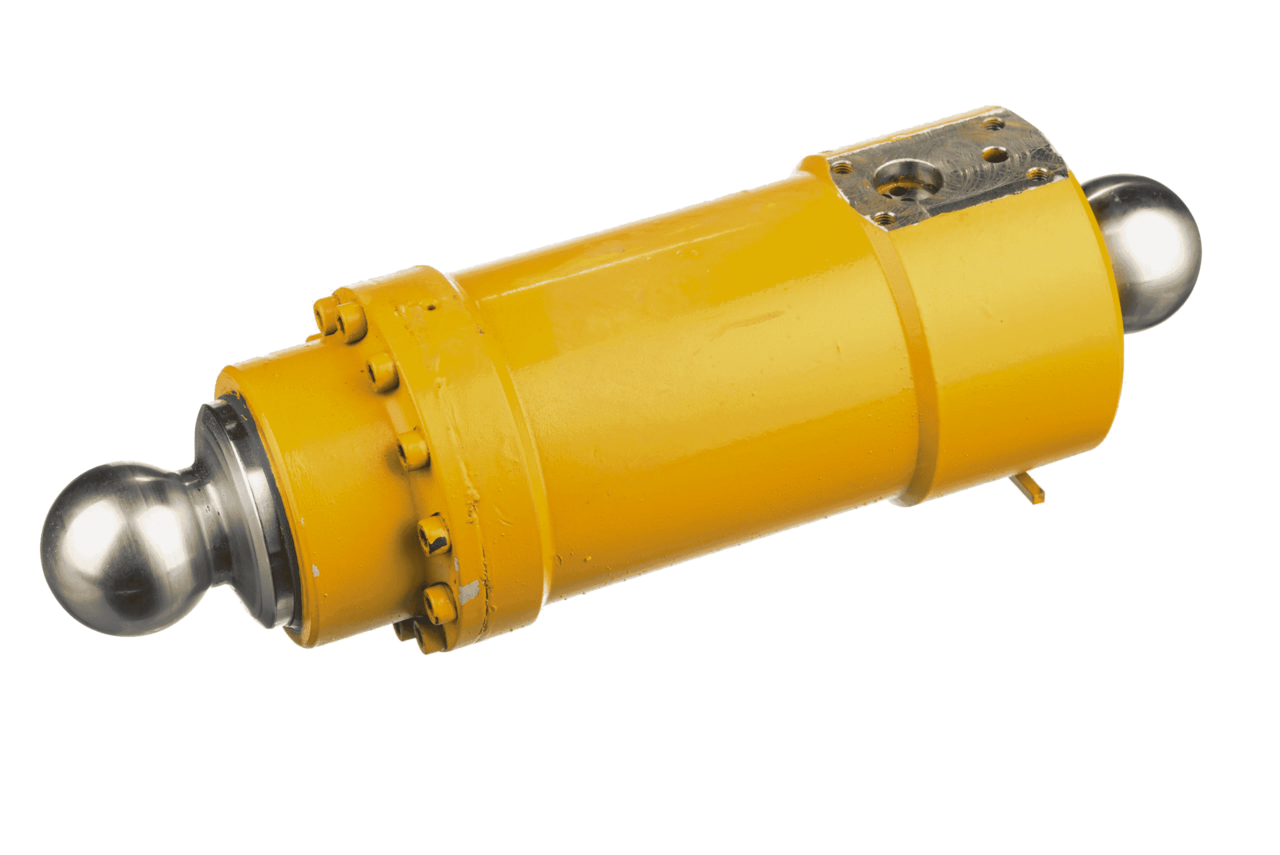

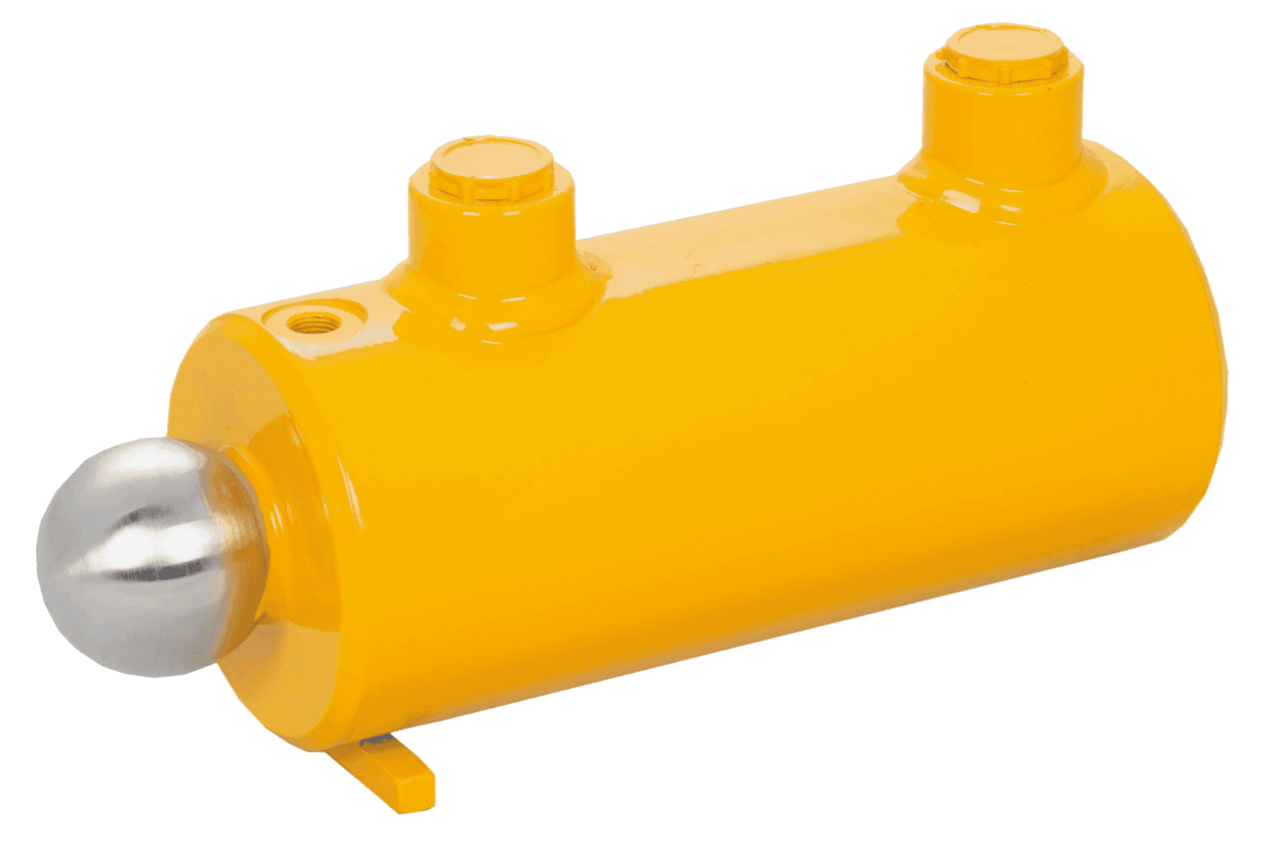

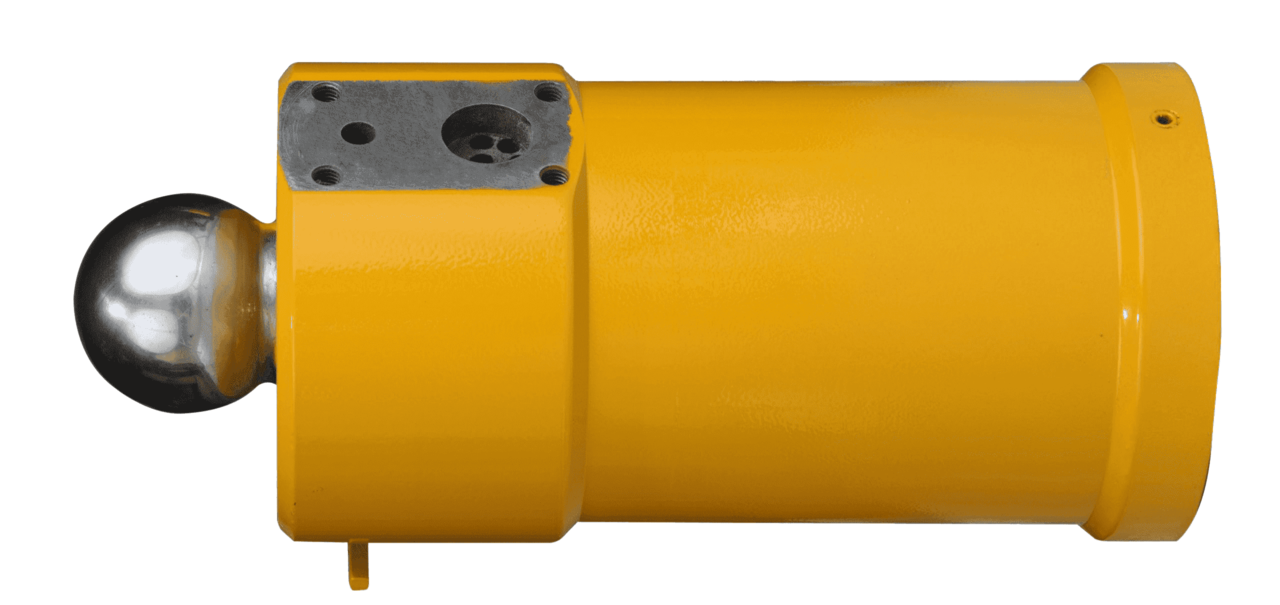

Component Breakdown (As Seen in Product Images):

-

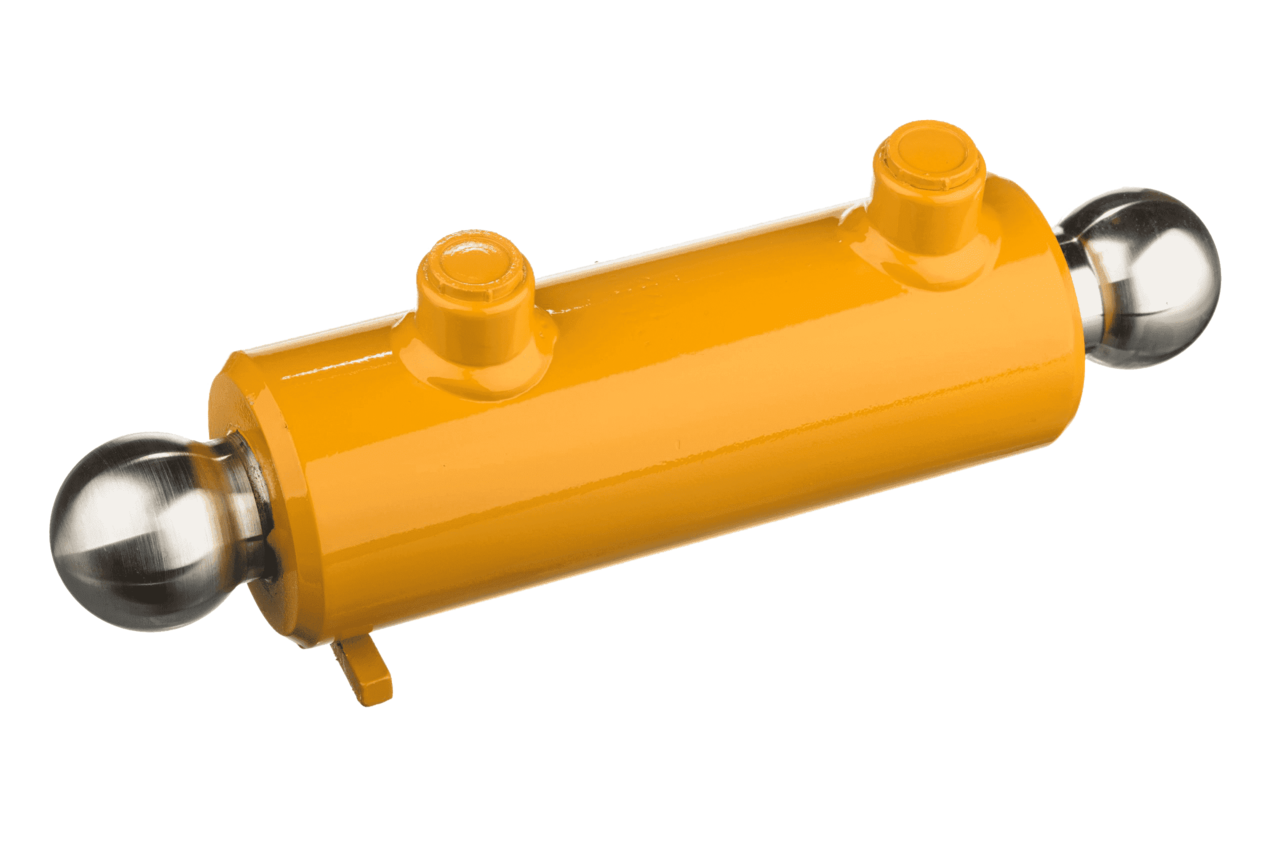

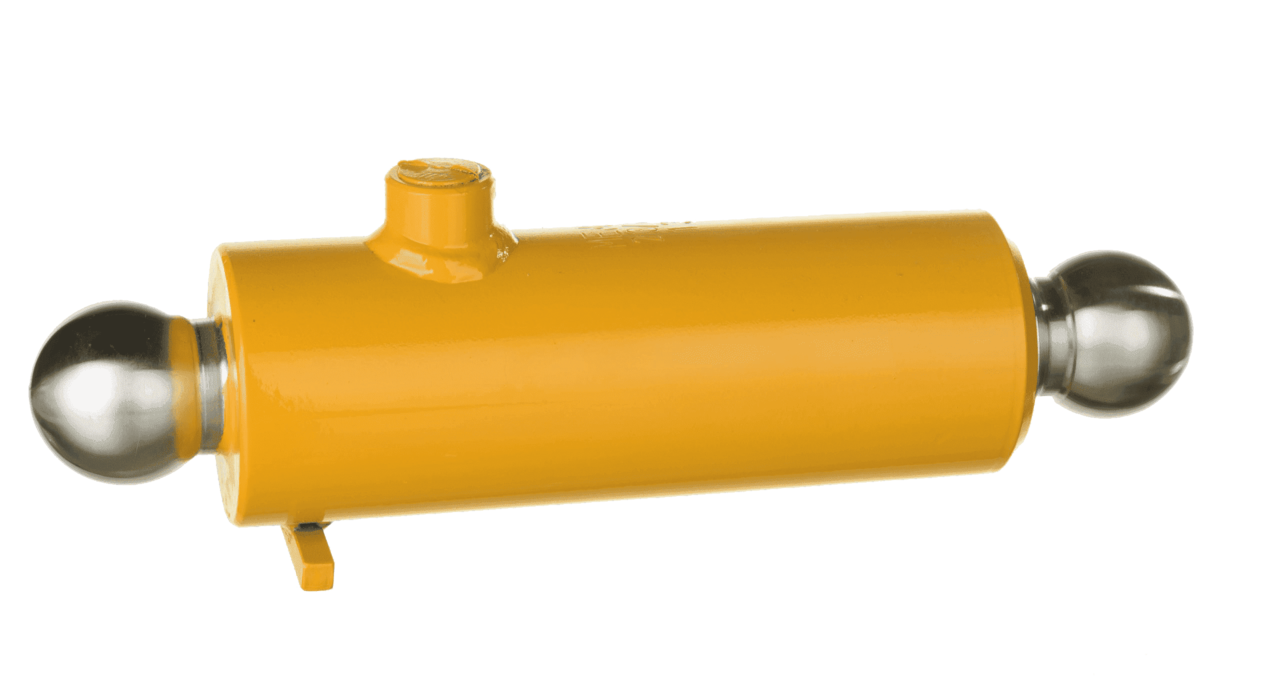

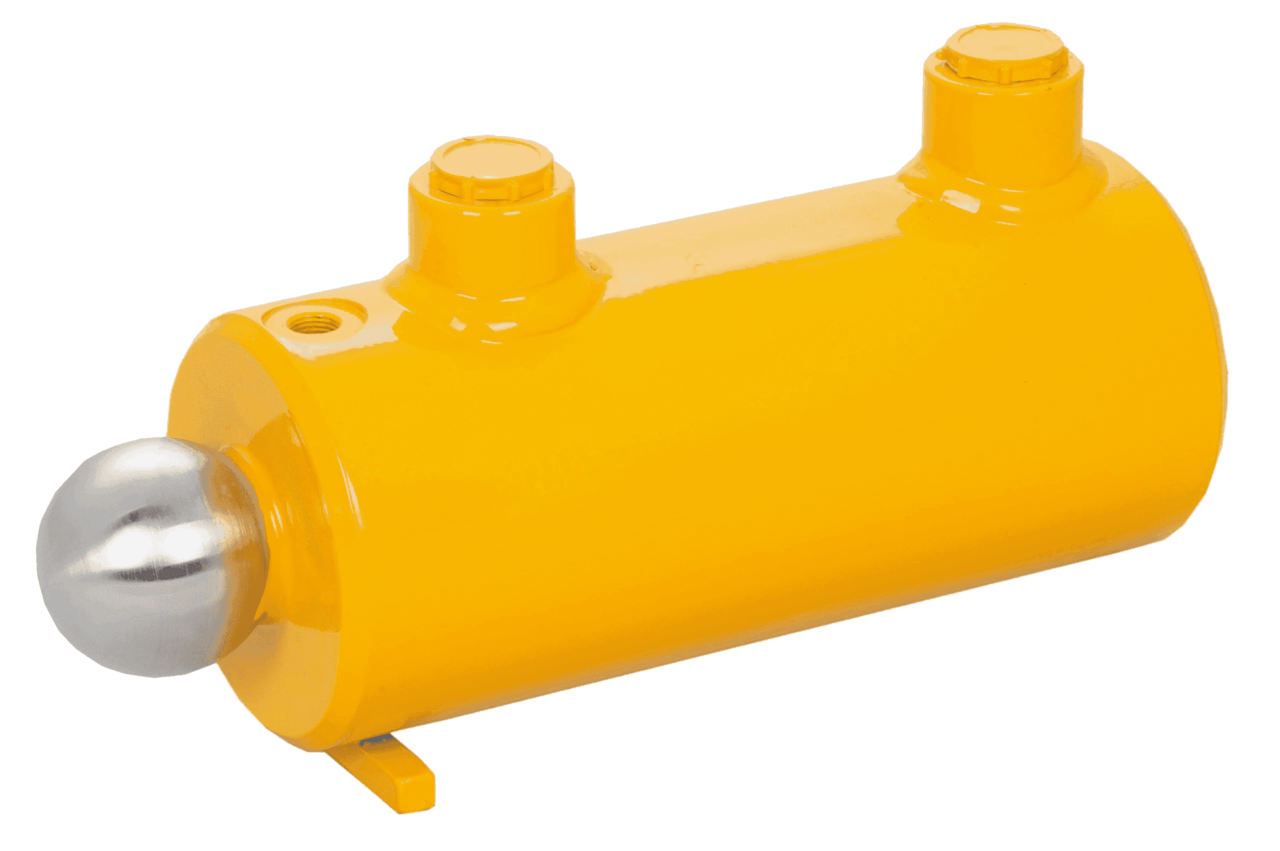

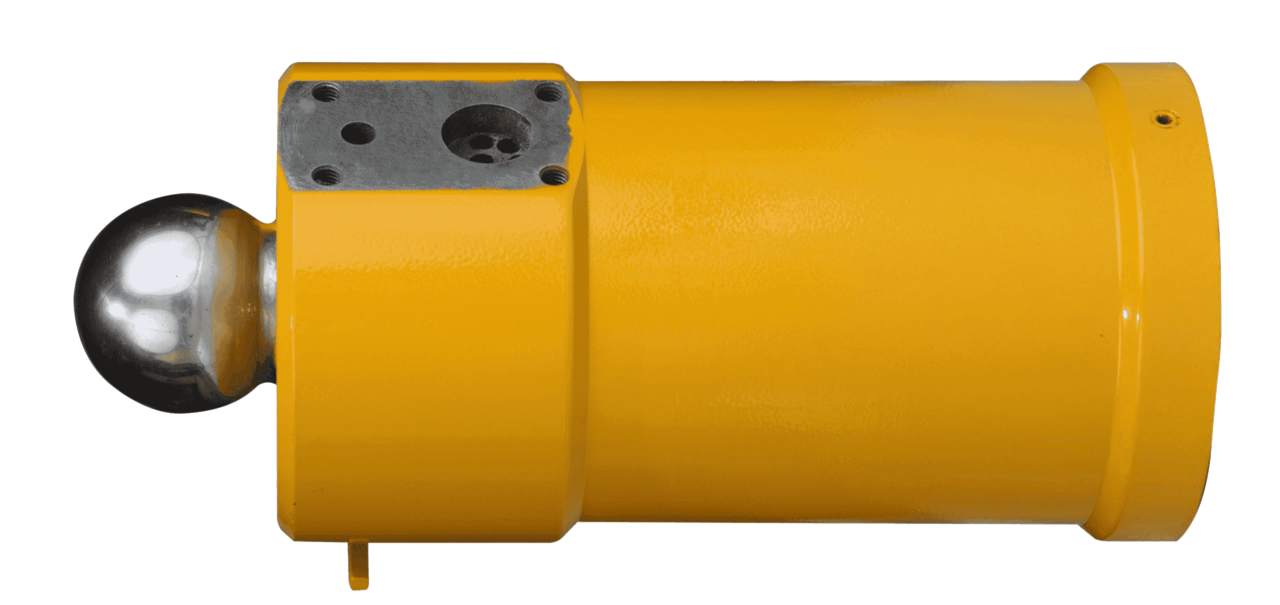

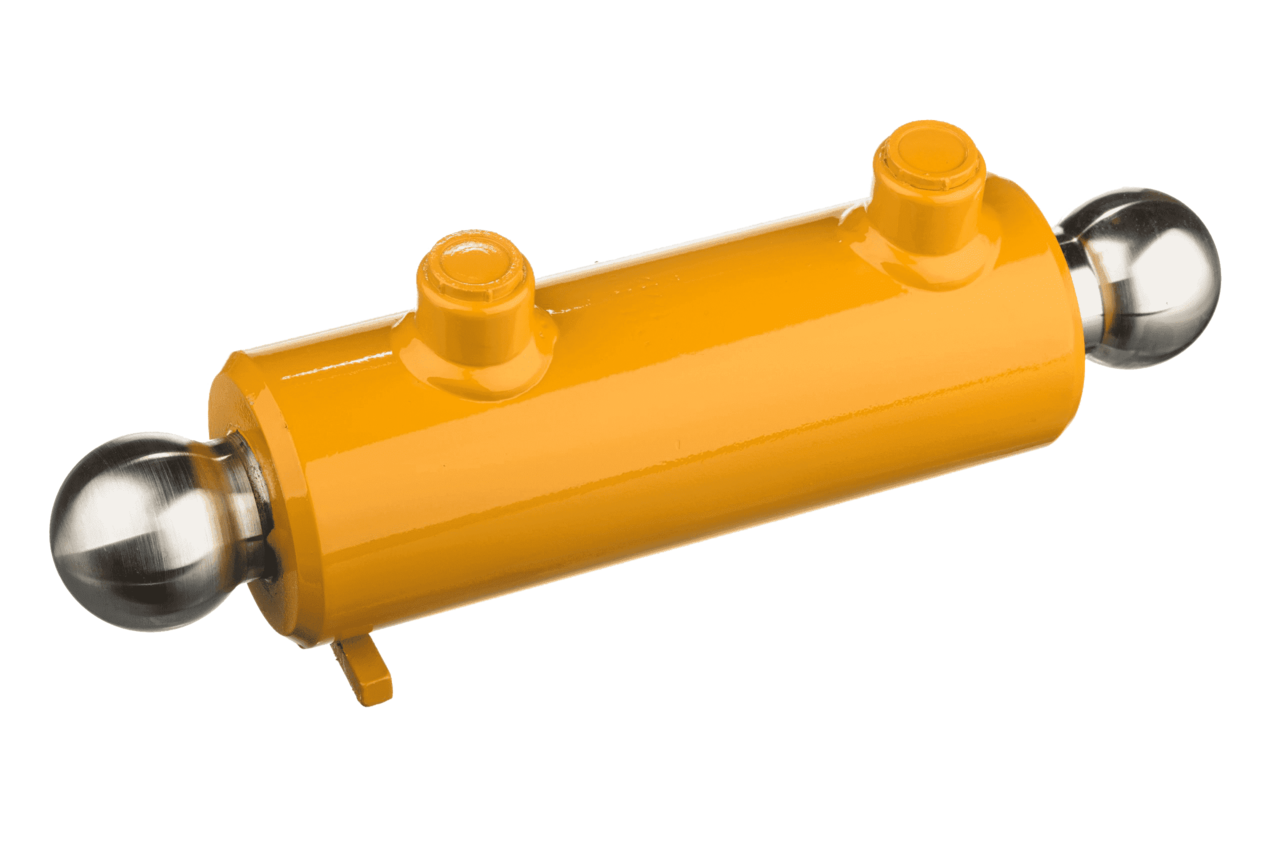

Complete Plunger Cylinders (Yellow Bodies):

Full cylinder assemblies with integrated mounting points, fluid ports, and a visible chromed plunger rod extending outward. -

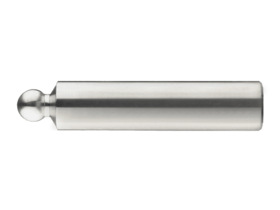

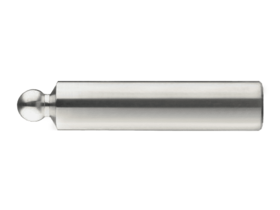

Plunger Rods (Silver Rods):

High-strength rods that convert hydraulic force into linear motion. These rods are chrome-plated for corrosion resistance and surface hardness. -

Cylinder Barrels / Housings (Black Cups):

Structural outer casings that house hydraulic fluid and the internal piston assembly. -

Piston Heads (Internal):

Attached to the plunger rod inside the barrel; these create the pressure chamber for force generation and directional movement. -

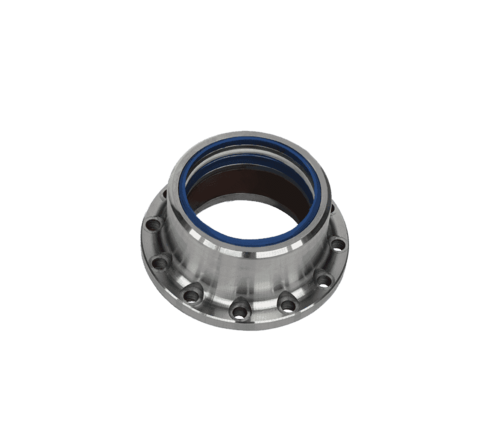

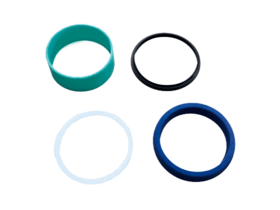

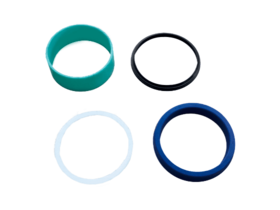

Hydraulic Seals (Green, Blue, Black Rings):

Made from oil-resistant elastomers, these seals ensure leak-free operation. They include piston seals, rod seals, and back-up rings. -

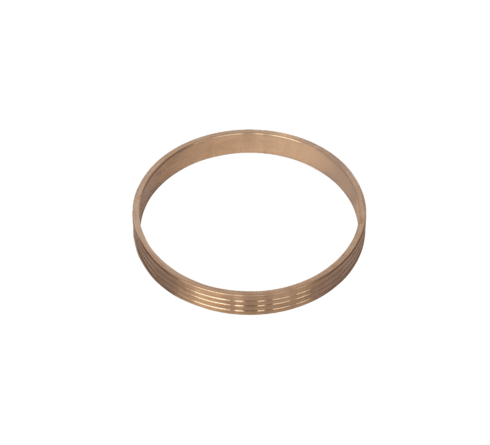

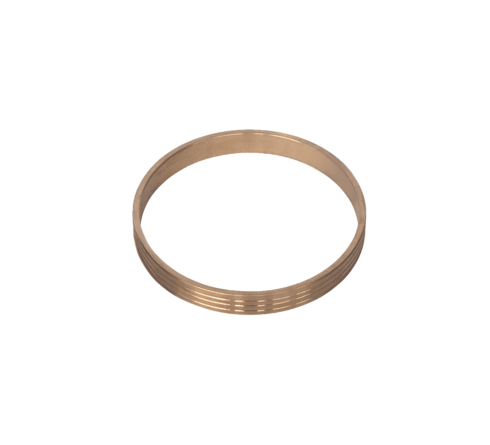

Wear Rings / Guide Rings (White & Brown Components):

Installed to absorb side loads, guide rod movement, and prevent metal-on-metal contact, thereby extending cylinder and seal life. -

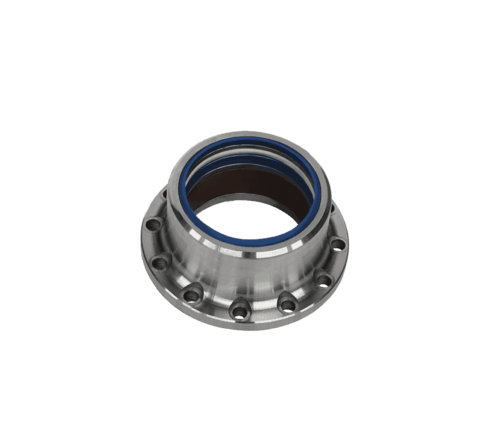

End Caps & Heads (Threaded Metal Components):

Seal the cylinder ends and include hydraulic ports for fluid in/outflow. They may also house integrated bearings or bushings. -

Mounting Hardware (Rod Ends / Spherical Bearings):

Allow for angular misalignment, ensuring smooth actuation and preventing stress or binding during operation.

Function Within a Putzmeister® Pump:

Plunger cylinders serve key auxiliary roles that support the overall concrete pumping process:

-

🔄 Actuating Hydraulic Valves:

Provides the thrust needed to shift valve spools or control fluid routing. -

⚙️ Linkage Control:

Moves mechanical linkages used in hopper operations, pipeline switching, or delivery direction control. -

🚪 Operating Small Access Gates or Doors:

Offers linear actuation for controlling gates that manage concrete or fluid movement. -

🧩 Adjusting Components:

Enables positional control for stabilizers, guide arms, or other pump features requiring remote hydraulic adjustment.

Why These Cylinders Matter:

Though not directly involved in pumping concrete, plunger cylinders are vital to the reliability and responsiveness of the entire hydraulic system. Malfunctions in these cylinders can lead to:

-

Inaccurate valve control

-

Inoperable flow gates

-

Pump shutdowns

-

Increased maintenance time and costs

Need the Right Fit?

To select the correct Putzmeister® Plunger Cylinder for your machine:

-

Refer to Putzmeister® OEM Parts Catalogs

-

Check cylinder diameter, stroke length, and mounting type

-

Verify seal kit compatibility

-

Match hydraulic pressure ratings and fluid types

Proper selection and maintenance of these components ensure seamless operation of your pump's control and support systems—keeping your worksite productive and your pump running efficiently.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...