Putzmeister

Putzmeister® Distributor Gearboxes & Accessories Series

Putzmeister® Distributor Gearboxes & Accessories Series

Putzmeister® Compatible Distributor Gearboxes & Accessories Series

Precision Power Transmission for High-Performance Concrete Pumping

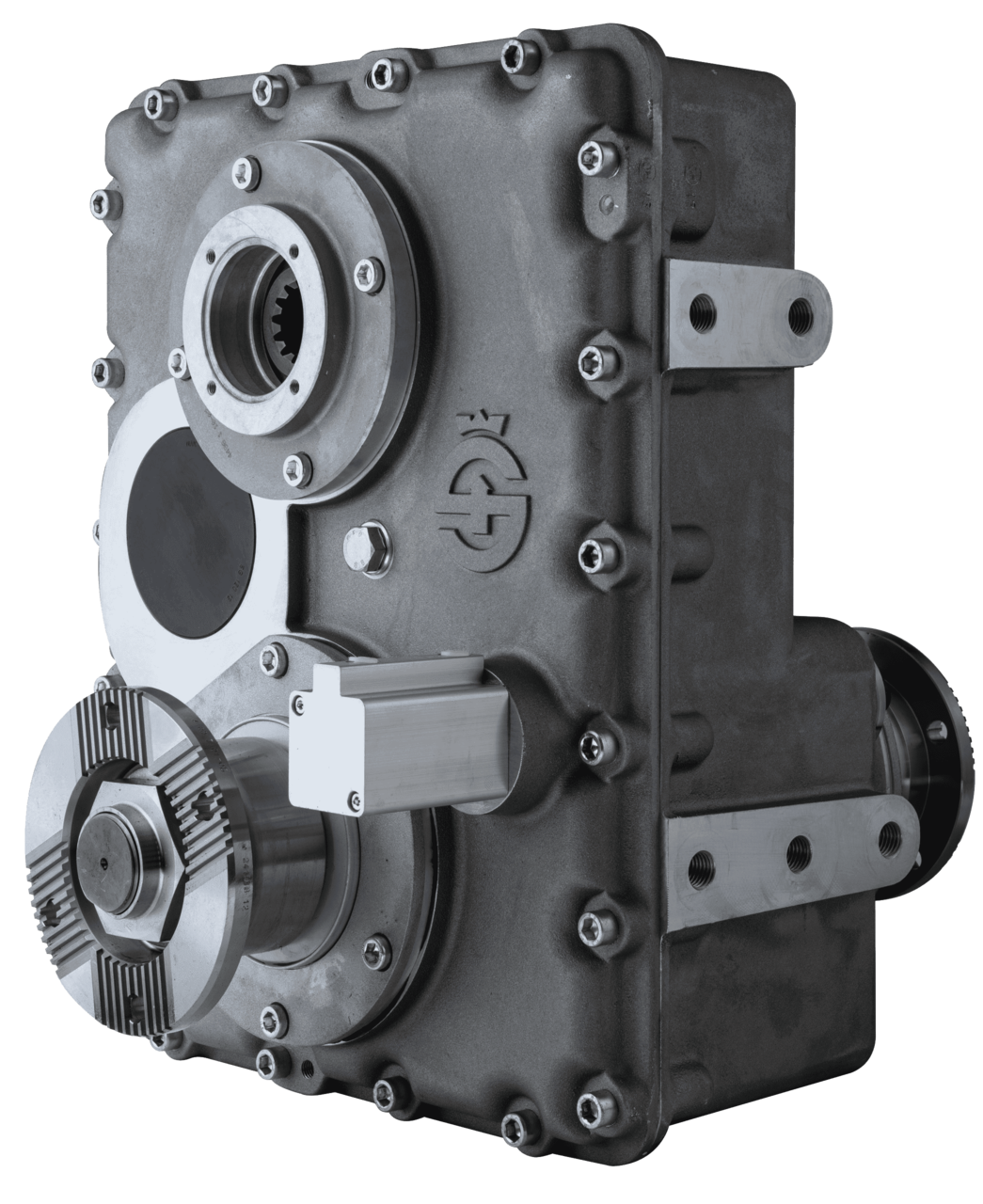

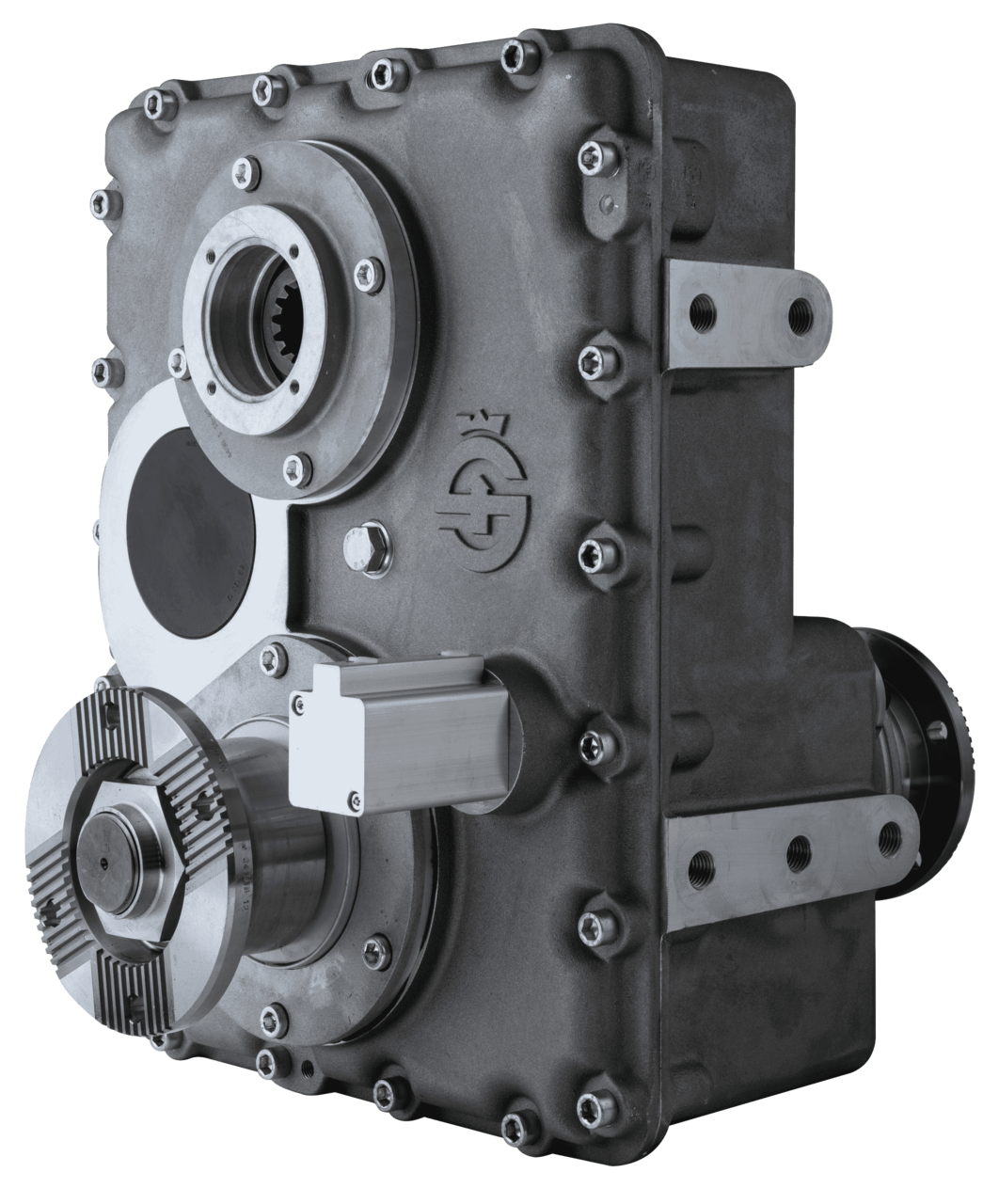

The Distributor Gearboxes & Accessories Series features robust gearbox assemblies and critical drivetrain components that enable reliable and efficient power distribution throughout the pump system. These units ensure optimal performance and synchronized operation of core components like agitators, hydraulic pumps, and auxiliary systems.

⚙️ Key Features & Advantages:

-

Efficient Torque Transfer

Engineered with precision gear ratios to ensure effective power distribution from hydraulic motors to pump subsystems. -

Heavy-Duty Construction

Built from high-grade alloy steel and advanced heat-treated components to endure high loads and extended operation cycles. -

Extended Service Life

Wear-resistant internals, premium seals, and high-precision bearings contribute to long operational lifespan with minimal maintenance. -

Compact & Integrated Design

Space-saving assemblies help simplify installation and service, ideal for confined or modular pump layouts. -

Versatile Configuration Options

Available in multiple input/output ratios and flange types to suit a wide range of Putzmeister® pump models and applications. -

Seamless System Integration

Designed for plug-and-play compatibility with Putzmeister® hydraulic and mechanical systems.

🛠️ Component Breakdown:

| Component | Function |

|---|---|

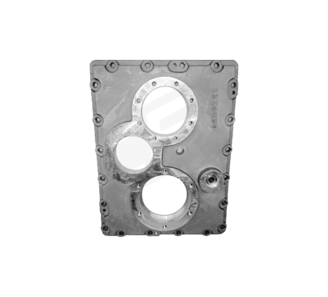

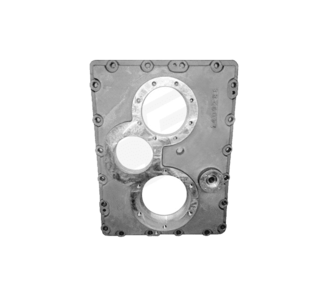

| Complete Gearbox Assemblies | House the internal gearing and shafts responsible for power distribution. |

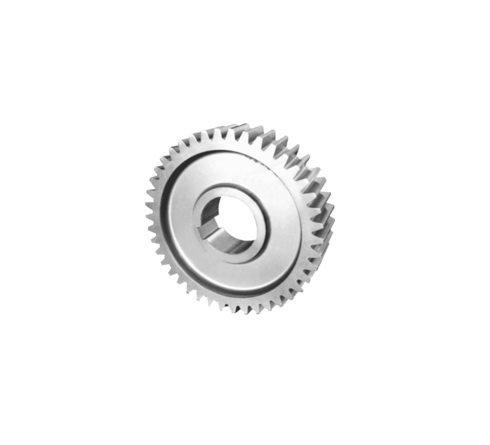

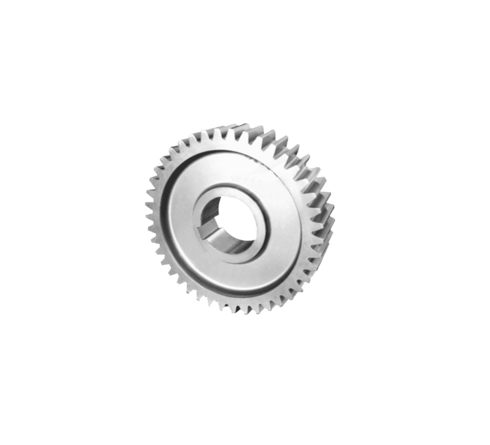

| Gears (Spur, Helical) | Transmit torque and adjust speed/torque within the gearbox. |

| Splined & Solid Shafts | Carry rotational power from the motor to internal gears or external components. |

| Bearings & Bushings | Ensure smooth shaft rotation and reduce wear under load. |

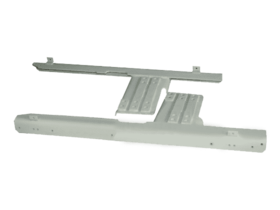

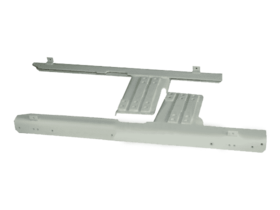

| Mounting Flanges/Brackets | Allow secure installation onto the frame or baseplate of the concrete pump. |

| Seals & Gaskets | Prevent fluid leakage and block dust and concrete contamination. |

| Couplings & Adapters | Facilitate precise connections between the gearbox and other drive components. |

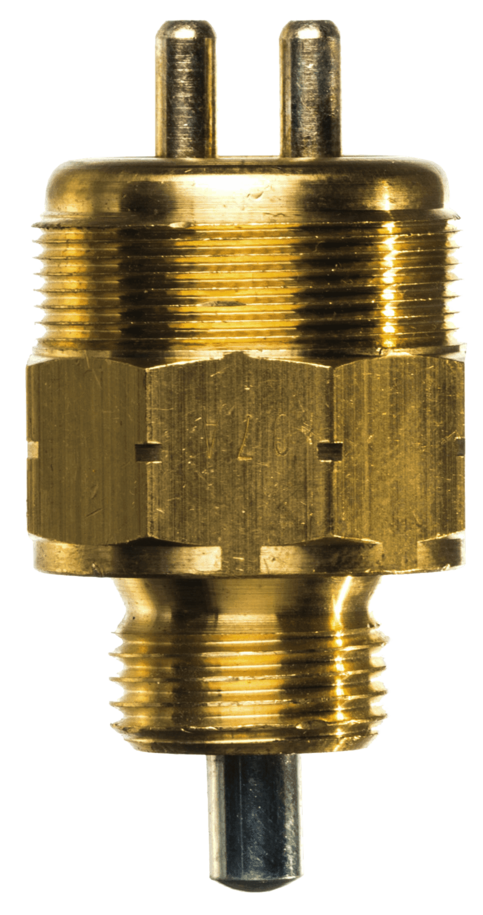

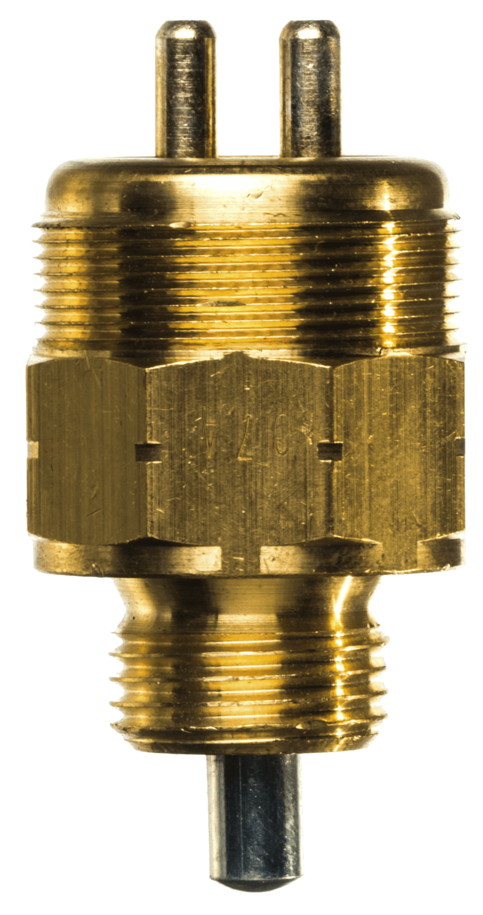

| Sensors & Switches | Provide real-time feedback on rotation speed, position, or pressure for automation/safety. |

🔄 Functional Role in Putzmeister® Concrete Pumps:

Distributor gearboxes are core power management units responsible for:

-

Transferring Power from the Hydraulic Motor

Driving downstream components such as:-

Agitators

-

Water pumps

-

Auxiliary circuits

-

Main hydraulic pump units

-

-

Controlling Speed & Torque

Through internal gear ratio selection, the gearbox matches output power to the load demands of each subsystem. -

Synchronizing Component Movements

Ensures coordinated function of mechanical systems, critical to maintaining concrete flow consistency.

📈 Benefits for Concrete Pumping Operations:

-

Increased Pump Efficiency

Optimal power distribution results in smoother operation and improved energy usage. -

Minimal Downtime

Reliable gear engagement and robust construction reduce mechanical failures. -

High Output Stability

Gear synchronization helps maintain steady concrete delivery without pulsation or interruption.

📘 Technical & Selection Support:

To ensure accurate fitment, correct gear ratio, and proper integration, always refer to the relevant Putzmeister® parts catalogs or technical drawings. Cross-reference part numbers and performance requirements with our support team to confirm compatibility

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...