Sermac

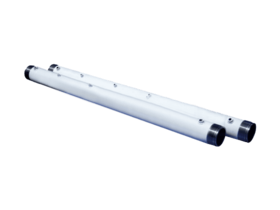

Sermac Main Pumping Cylinders

Sermac Main Pumping Cylinders

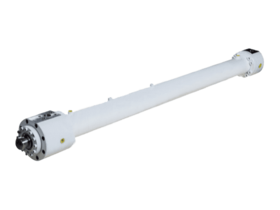

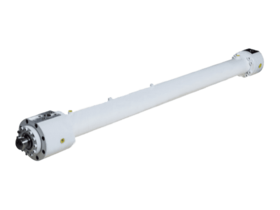

Main pumping cylinders are central to the operation of Sermac concrete pumps. These heavy-duty hydraulic cylinders alternate between suction and pressure strokes to draw concrete from the hopper and force it into the delivery line. Operating under high pressure and continuous motion, these cylinders are engineered to deliver maximum performance, durability, and efficiency even in the most demanding jobsite conditions.

Key Features:

-

High-Pressure Hydraulic Design: Double-acting cylinders built to handle the significant hydraulic forces involved in concrete pumping operations.

-

Heavy-Duty Construction: Fabricated from high-strength, wear-resistant steel to withstand internal abrasion and external stress.

-

Precision Machining: Ensures smooth piston movement and consistent pressure output, minimizing mechanical losses.

-

Integrated Sealing System: Equipped with high-performance seals to prevent leakage of hydraulic oil and concrete slurry.

-

Port Configuration: Includes hydraulic ports for pressure and return lines, matched to Sermac pump systems.

-

Corrosion and Wear Protection: Interior surfaces often treated or lined to reduce wear from abrasive concrete mixes.

Applications (Within Sermac Pumping Systems):

-

Suction Stroke: Draws concrete into the cylinder from the hopper.

-

Pressure Stroke: Forces concrete through the delivery pipeline to the discharge point.

-

Piston Seal Support: Maintains seal integrity for efficient, leak-free operation.

-

Flow Regulation: Enables continuous, alternating action between dual cylinders for uninterrupted concrete flow.

Component Breakdown (Based on Typical Assemblies):

-

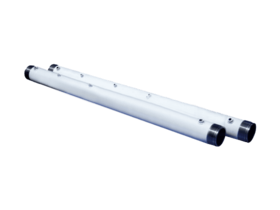

Main Cylinder Barrel: The large-diameter cylindrical body housing the piston movement.

-

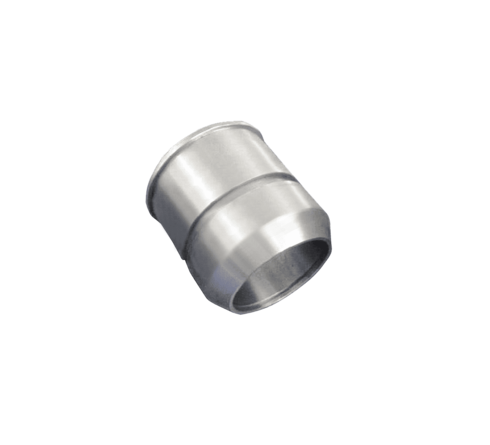

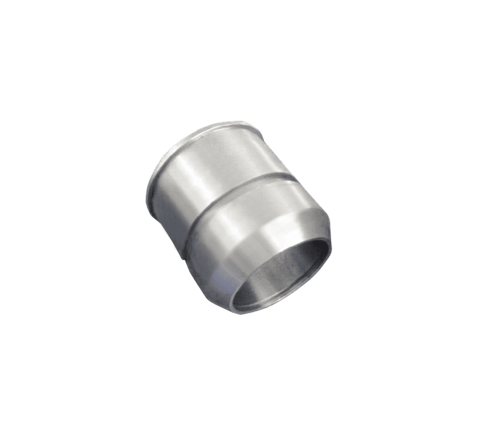

Cylinder Liner (or Sleeve): Replaceable inner sleeve providing wear protection and extending service life.

-

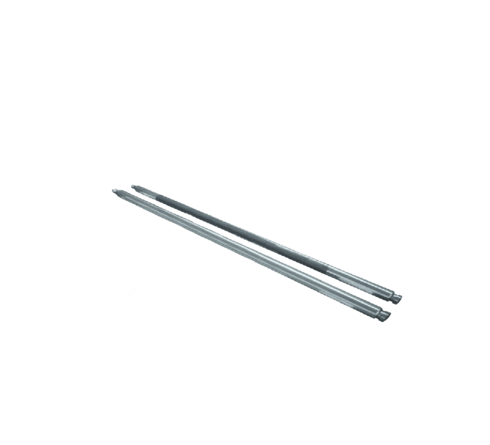

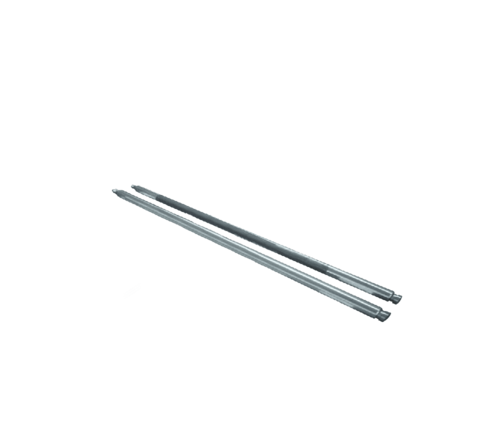

Piston Rod: Transfers force from the hydraulic piston to the concrete.

-

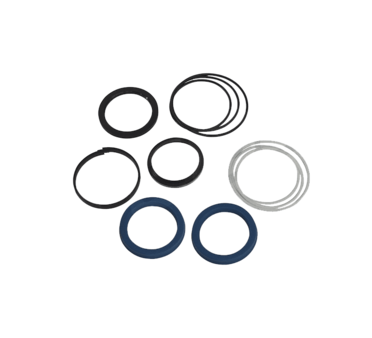

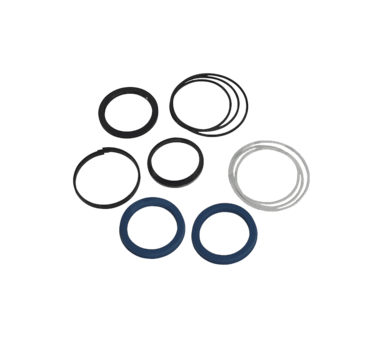

Seal Kits and Rings: Used to prevent leakage and maintain pressure integrity throughout the stroke cycle.

-

Tie Rods / Connecting Rods: Structural elements linking pistons to hydraulic actuators or other moving parts in the assembly.

Identification Guidelines:

To ensure accurate selection of main pumping cylinders or replacement parts for your Sermac pump:

-

Confirm the exact Sermac model and serial number.

-

Refer to the OEM parts manual or technical diagram.

-

Inspect for part numbers, stampings, or dimensional markings on the current cylinder.

-

Measure bore diameter, rod diameter, and stroke length.

-

Verify mounting type and hydraulic connection specifications.

Note:

Using genuine or OEM-compatible main pumping cylinders is essential for maintaining flow efficiency, pump reliability, and equipment lifespan. Always consult with a certified Sermac parts distributor for component compatibility and installation support.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...