Schwing

Schwing Wear Parts

Schwing Wear Parts

Wear parts in Schwing concrete pumps are vital components exposed to high levels of stress and abrasion, due to the constant movement of concrete slurry and the high pressures associated with pumping. These parts are engineered to withstand such challenging conditions, but they inevitably wear out over time. Regular replacement of wear parts is essential for maintaining the pump's efficiency, minimizing downtime, and ensuring a long service life. These parts are often made from durable materials such as hardened metals, specialized alloys, or engineered polymers designed to resist the harsh environment inside the pump.

Key Features

-

High Wear Resistance: Manufactured from materials known for their exceptional durability and resistance to the abrasive nature of concrete, including hardened steel, tungsten carbide coatings, and specialized polymers.

-

Precision Fit: Each wear part is carefully machined or molded to precise dimensions to ensure correct function and sealing within the pump's assembly.

-

Application-Specific Design: Designed to fit specific locations within the pump, such as the pumping cylinders, rock valve, hopper, or delivery lines, to effectively handle the stresses of concrete pumping.

-

Easily Replaceable: Wear parts are designed for easy replacement, allowing for minimal downtime when components reach their wear limit.

-

Contributes to Sealing: Many wear parts also assist in sealing critical areas to prevent concrete leakage and help maintain the pressure within the pumping system.

Potential Applications

Wear parts can be found throughout various sections of the concrete pump, including:

-

Main Pumping Cylinders: Parts like wear sleeves and piston wear rings, which are subject to constant friction.

-

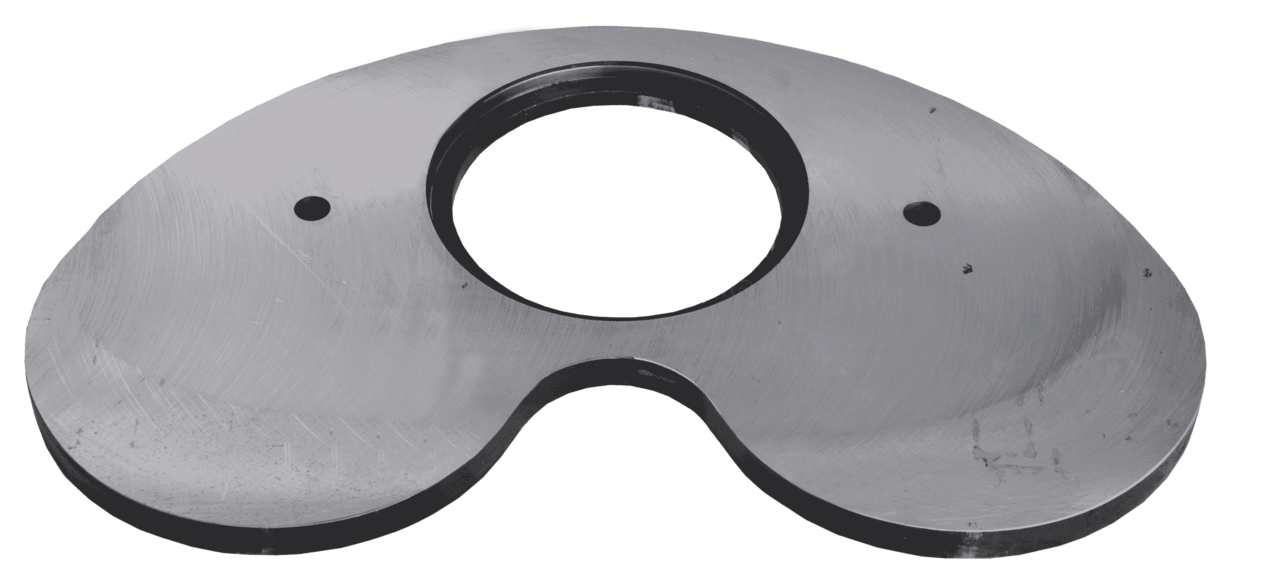

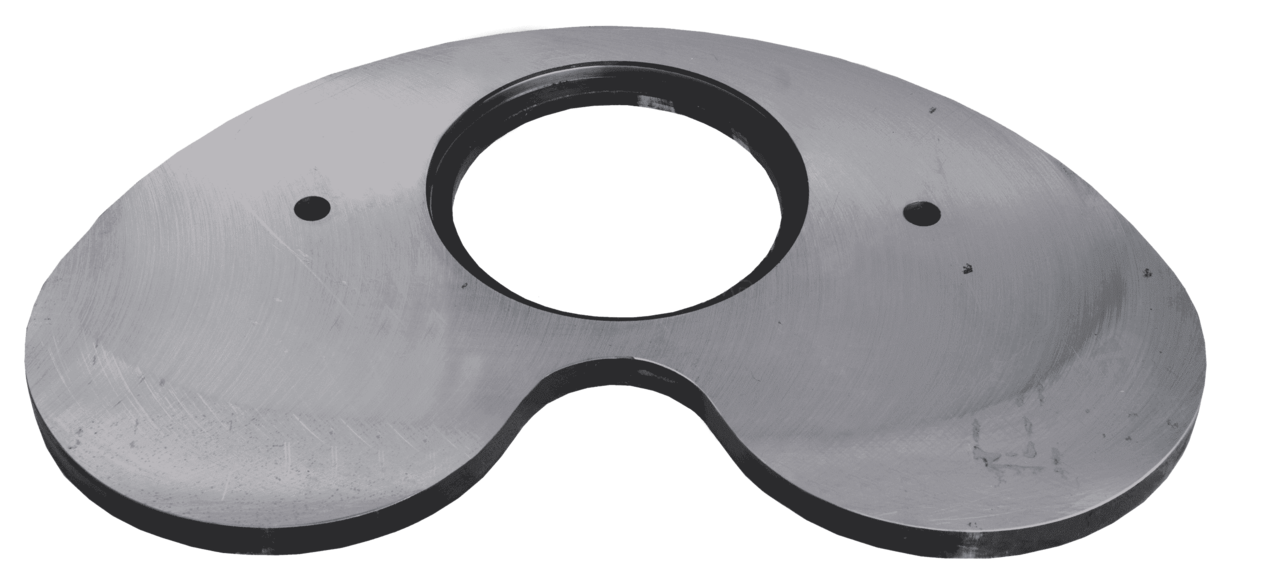

Rock Valve (S-Valve): Wear rings, wear plates, and sealing elements are essential for the valve's operation and to prevent leaks.

-

Hopper: Wear liners or plates are placed in areas where concrete slurry causes abrasive wear.

-

Delivery Line Connections: Seals and wear rings in couplings and flanges to maintain effective connections and prevent leaks.

-

Agitator (If Applicable): Wear plates or paddles inside the agitator, which mix the concrete.

-

Sealing Components: Various seals and gaskets that naturally degrade over time due to friction, pressure, and exposure to concrete.

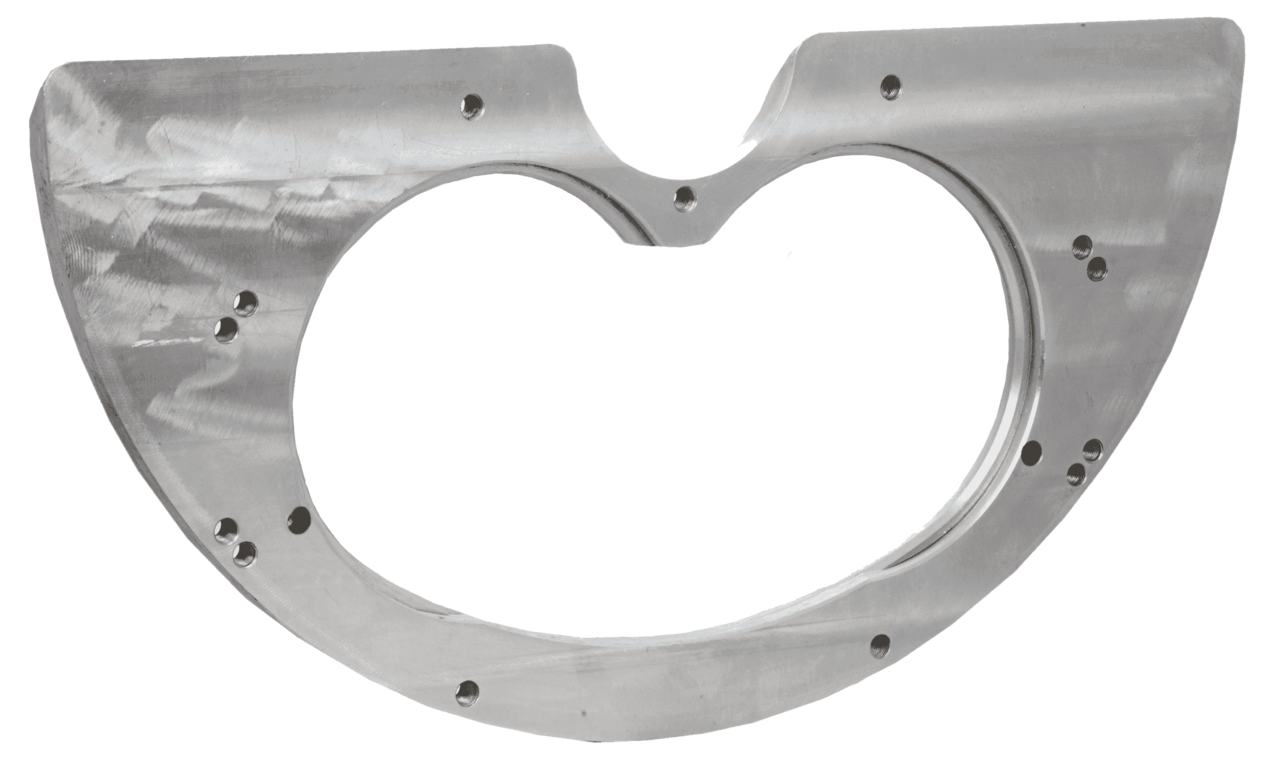

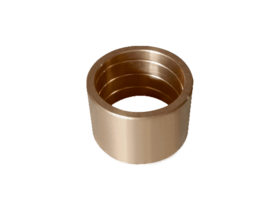

Common Wear Parts (Identified Based on Visual Cues)

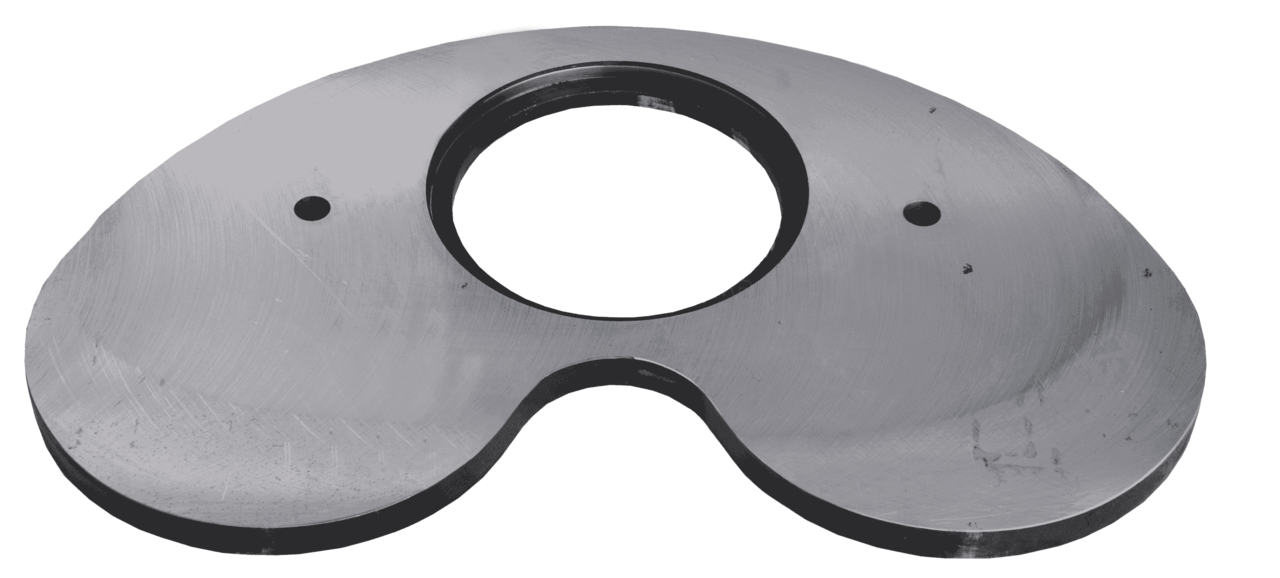

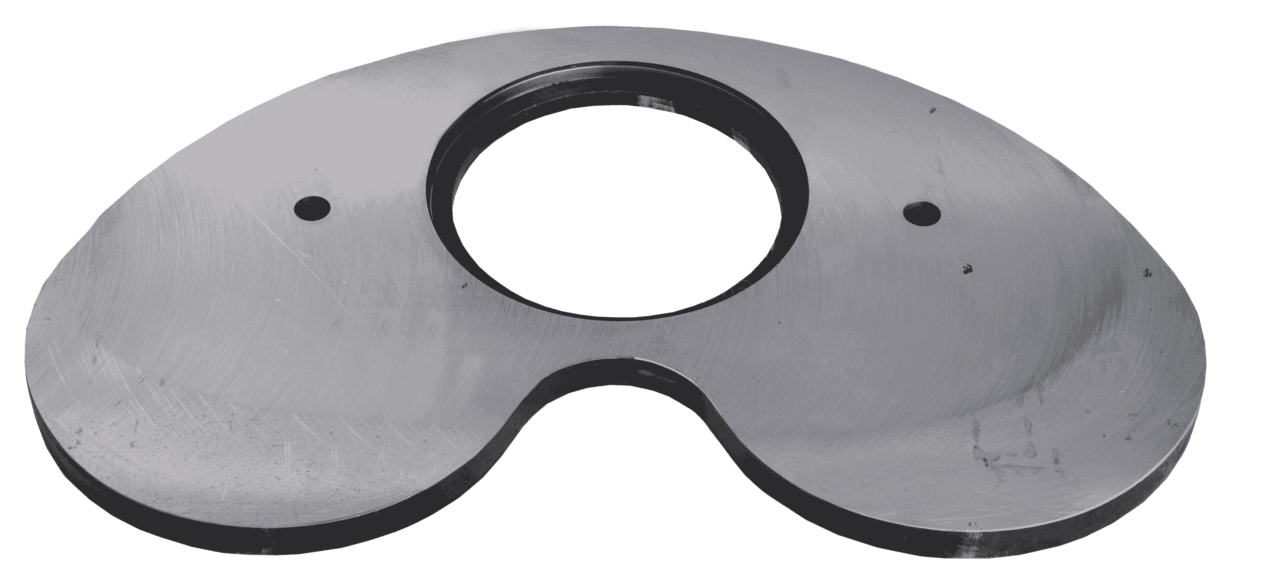

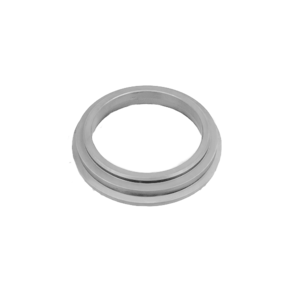

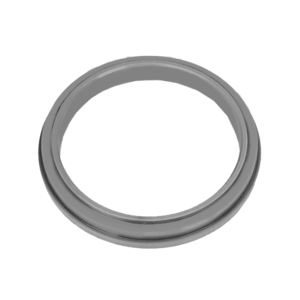

The wear parts shown are indicative of the many components that suffer wear and tear during concrete pumping operations:

| Component Type | Description |

|---|---|

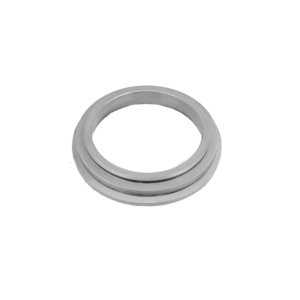

| Metallic Rings and Sleeves | Cylindrical components, often made of metal, used in pumping cylinders, rock valve, or other moving parts. Their internal grooves or steps suggest a design to retain lubricant or seals. |

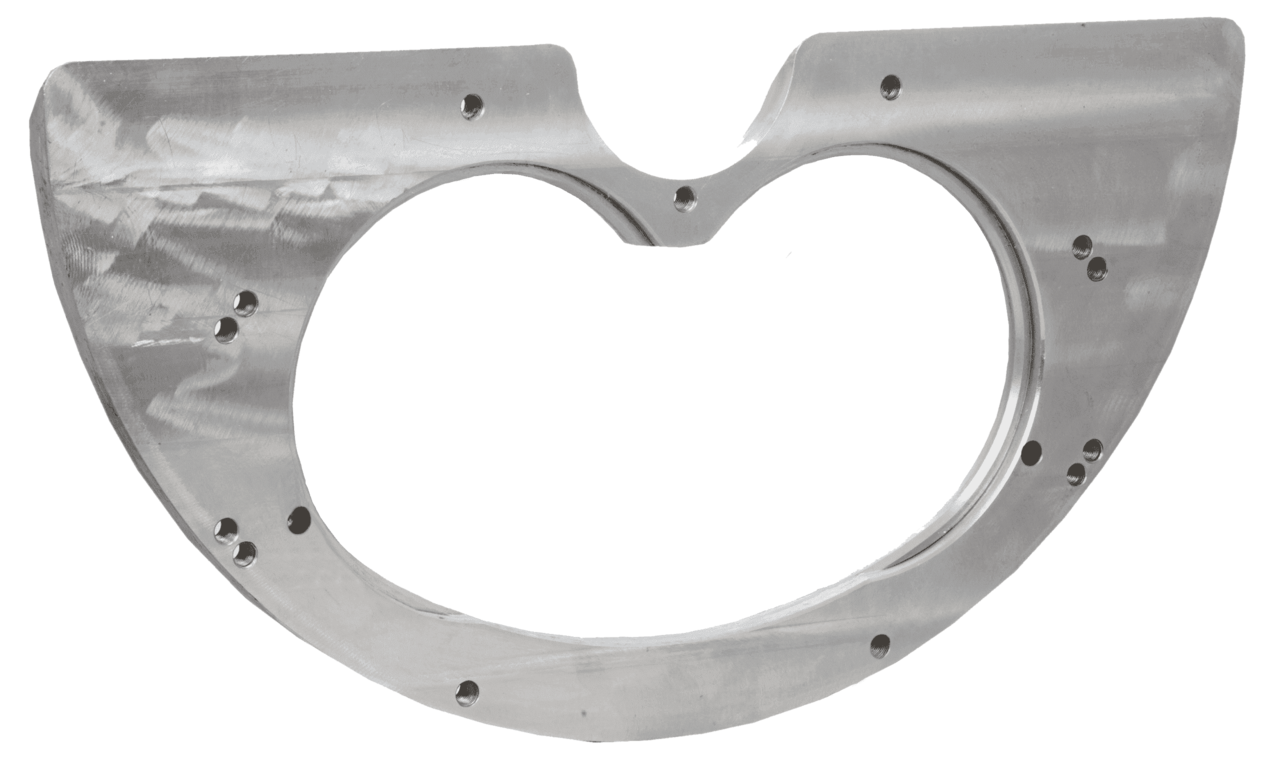

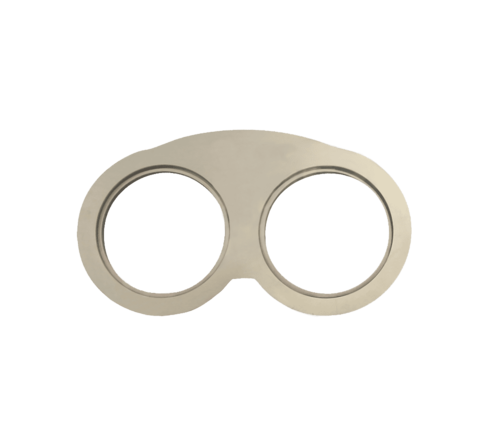

| Figure-Eight Shaped Components | Likely wear plates or sealing elements specifically designed for the oscillating rock valve. |

| Circular and Oval Rings (Black, Brown, Silver) | O-rings, U-cups, and other seals that help prevent concrete or hydraulic fluid leakage. These may be made from polymers or metals. |

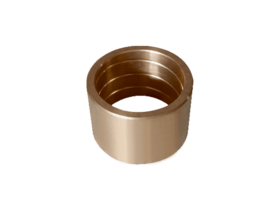

| Flanged Components with Bushings | Parts with flanges and inserted wear-resistant bushings, typically used at pivot points where rotational movement occurs. |

| Segmented Metallic Components | Likely wear rings or guides that fit around cylindrical components to manage wear during movement. |

| Yellow Polymer Components | Potential wear sleeves or guides made of durable polymer materials to resist abrasion in high-stress areas. |

Selection Guidelines

To ensure the correct replacement wear parts for a Schwing concrete pump, please consider the following:

-

Model and Serial Number: Confirm the exact model and serial number of your Schwing concrete pump to ensure compatibility.

-

Existing Part Number: Look for the part number on the worn component for easy identification.

-

Location within Pump Assembly: Specify where the part fits within the pump, such as the main cylinder, rock valve, or hopper.

-

Dimensions and Identifying Marks: Provide the exact dimensions and any additional marks to ensure an accurate replacement.

-

Use of Genuine Schwing Parts: Always use genuine Schwing parts for optimal performance, as non-original components can cause premature failure, reduced efficiency, and potential damage to other pump components.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...