Schwing

Schwing Water Pump

Schwing Water Pump

The water pump in a Schwing concrete pump is a vital component designed to provide high-pressure water for cleaning the concrete delivery system, including the hopper, pumping cylinders, and delivery lines. Additionally, the water pump may serve other functions such as cooling hydraulic systems or aiding dust suppression at the pour site. A reliable water pump ensures the efficient maintenance of the equipment and extends the life of the concrete pump by facilitating effective cleanup.

Key Features

-

Durable and Corrosion-Resistant Construction: Made from materials such as cast iron, stainless steel, or specialized alloys to withstand wear and corrosion, especially when handling water with abrasive concrete residue.

-

Self-Priming Design: Many Schwing water pumps are self-priming, which means they can draw water from a source without needing to be manually filled, ensuring ease of use.

-

High Flow Rate and Pressure: Engineered to provide sufficient flow and pressure to effectively clean the concrete pumping system after each use.

-

Drive Type Flexibility: Can be powered by either an electric motor or a hydraulic motor, depending on the pump model and the system configuration.

-

Sealed for Leak Prevention: Incorporates high-quality seals to prevent water leakage and maintain optimal performance.

-

Compact and Space-Efficient: Designed to fit within the limited available space on a concrete pump, without compromising on performance.

Common Applications

-

Cleaning the Hopper: Facilitates cleaning the concrete hopper to remove residual concrete after pumping operations.

-

Flushing Pumping Cylinders and Delivery Lines: Ensures that residual concrete is removed from the cylinders and delivery lines, keeping the system ready for the next job.

-

High-Pressure Cleaning System: Supplies water to a high-pressure cleaning system (if equipped) for more intensive cleaning of the pump components.

-

Hydraulic Cooling (If Equipped): Some models use the water pump to help cool hydraulic oil coolers and heat exchangers.

-

Dust Suppression: Provides water to aid in dust suppression at the end of the boom during concrete placement.

Typical Components in This Category

| Component Type | Description |

|---|---|

| Water Pump Unit | Main centrifugal pump with volute housing, inlet/outlet ports, and drive shaft. |

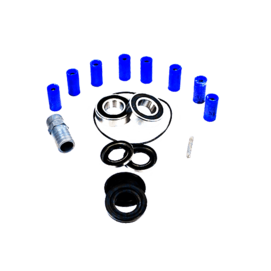

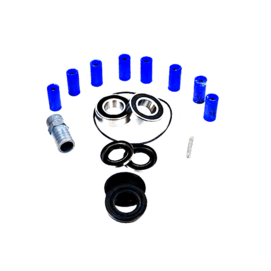

| Repair Kit / Seal Set | Contains seals and O-rings necessary for pump maintenance and leak prevention. |

| Pump Housing | The outer casing of the pump that houses the internal components like the impeller. |

| Impellers | Rotating components that move water through the pump. Typically made of durable, corrosion-resistant material. |

| Drive Components | Includes motor connections (electric or hydraulic) for powering the pump. |

| Mounting Brackets | Hardware for securely mounting the pump to the concrete pump system. |

| Hoses and Fittings | Various hoses and fittings for connecting the water pump to the system, such as the outlet for cleaning. |

Selection Guidelines

When selecting or replacing a water pump, ensure compatibility by confirming the following:

-

Pump Model and Serial Number: Ensures you choose the correct pump model for your specific concrete pump.

-

Drive Type: Determine whether the pump is powered by an electric or hydraulic motor.

-

Required Flow Rate and Pressure: Make sure the pump's specifications meet the needs of your cleaning system.

-

Existing Part Number: If replacing a component, check the existing part number for direct compatibility.

-

System Requirements: Consider any additional features, such as cooling or dust suppression, that your pump may be designed to handle.

Portfolio

View all-

Mixers Parts

Explore our collection of high-quality parts for top concrete mixer brands including...

-

Pumps Parts

Find premium parts for leading concrete pump brands like Putzmeister, CIFA, SERMAC,...

-

WAM Products

An industry leader in silo equipment and material conveying solutions for solid...